A Method of Sequentially Scanning Double Laser Beams for Precisely Machining Sapphire

A laser processing head, sapphire technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problem that the processing part is difficult to meet the surface roughness requirements of optical components, and the ultrafast laser beam energy density requires high and high energy density. The use of precision optics and other issues can reduce the processing time and equipment cost, improve the processing accuracy, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The invention provides a method for sequentially scanning double laser beams to precisely process sapphire, comprising the following steps:

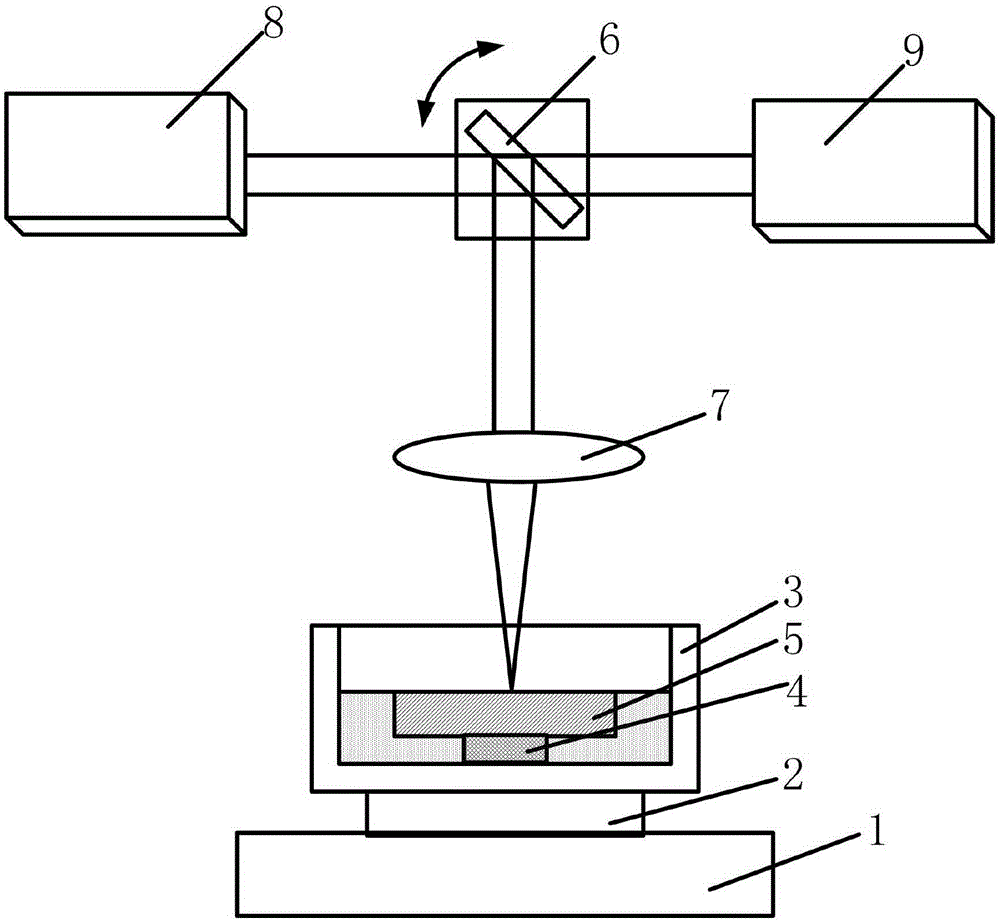

[0029] (1) if figure 1 As shown, an ultrasonic generator 2 is installed on the workbench 1, and a container 3 with a concave opening is fixedly installed above the ultrasonic generator 2. A clamping device 4 is provided in the container 3, and the sapphire workpiece 5 is passed through the clamp. The holding device 4 is fixed in the container; the purpose of the holding device 4 is to fix the sapphire workpiece 5, and its structure can be realized by using the prior art.

[0030] Said container 3 is equipped with a sapphire chemical etching solution, and the liquid level of the sapphire chemical etching solution is level with the upper surface of the sapphire workpiece 5 or lower by 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com