Vehicle-mounted particle concentration detector

A particle concentration and detector technology, applied in the field of detectors, can solve the problems of finding out the concentration change, particle damage to the internal structure, only detecting the particle concentration inside the vehicle, or the particle concentration outside the vehicle, etc., so as to achieve comprehensive detection results and avoid particulate matter. effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples.

[0020] Up, down, left and right described in the present invention are based on figure 1 The direction in which the detector is placed is determined. At the same time, the low concentration and high concentration described in the present invention do not need to be defined by specific values, and are obtained by comparing two environments with different concentrations.

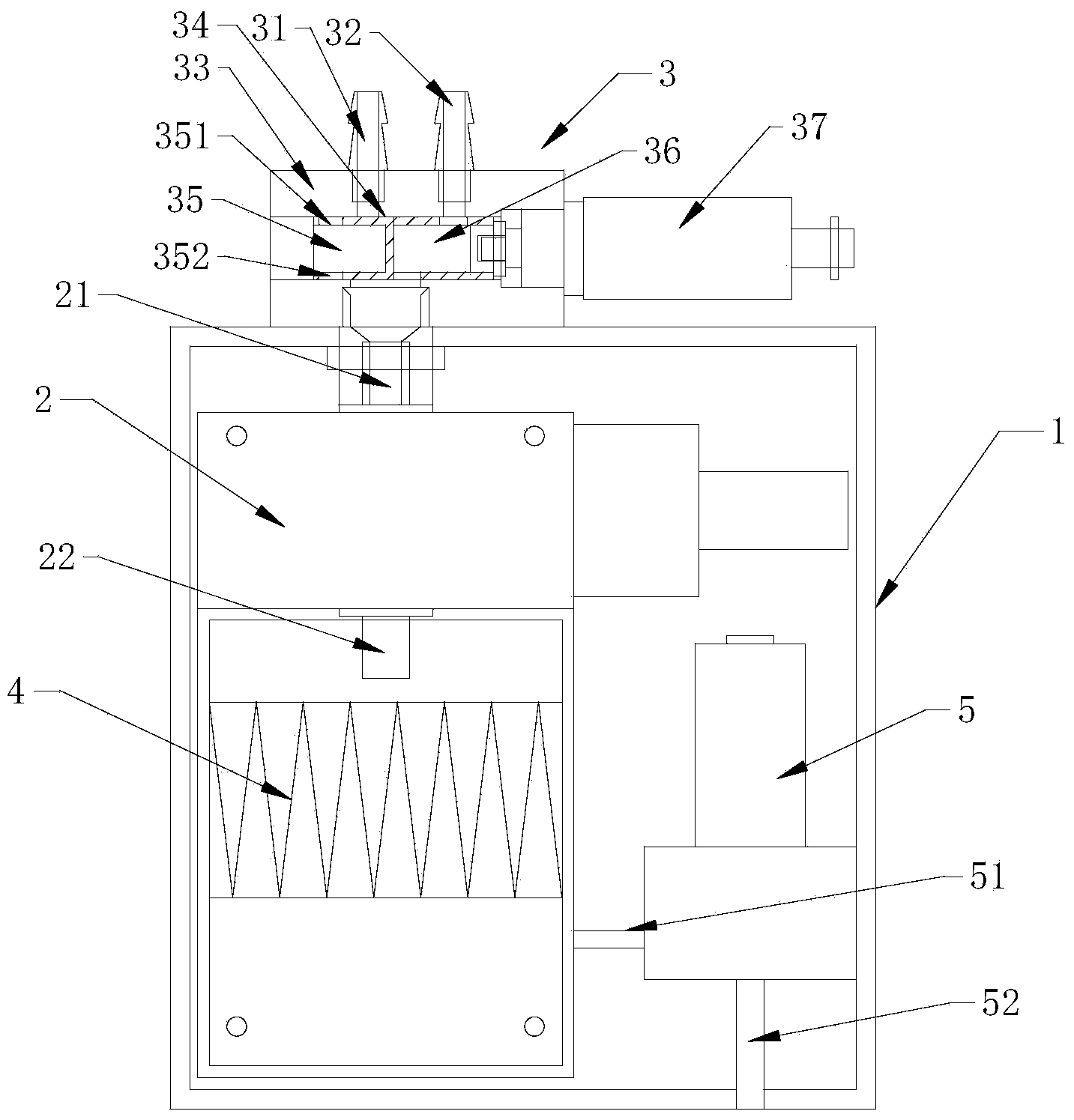

[0021] Such as figure 1 , 2 As shown, a vehicle-mounted particle concentration detector includes a housing, a laser dust concentration sensor, a sampling pump, and a sampling distribution valve.

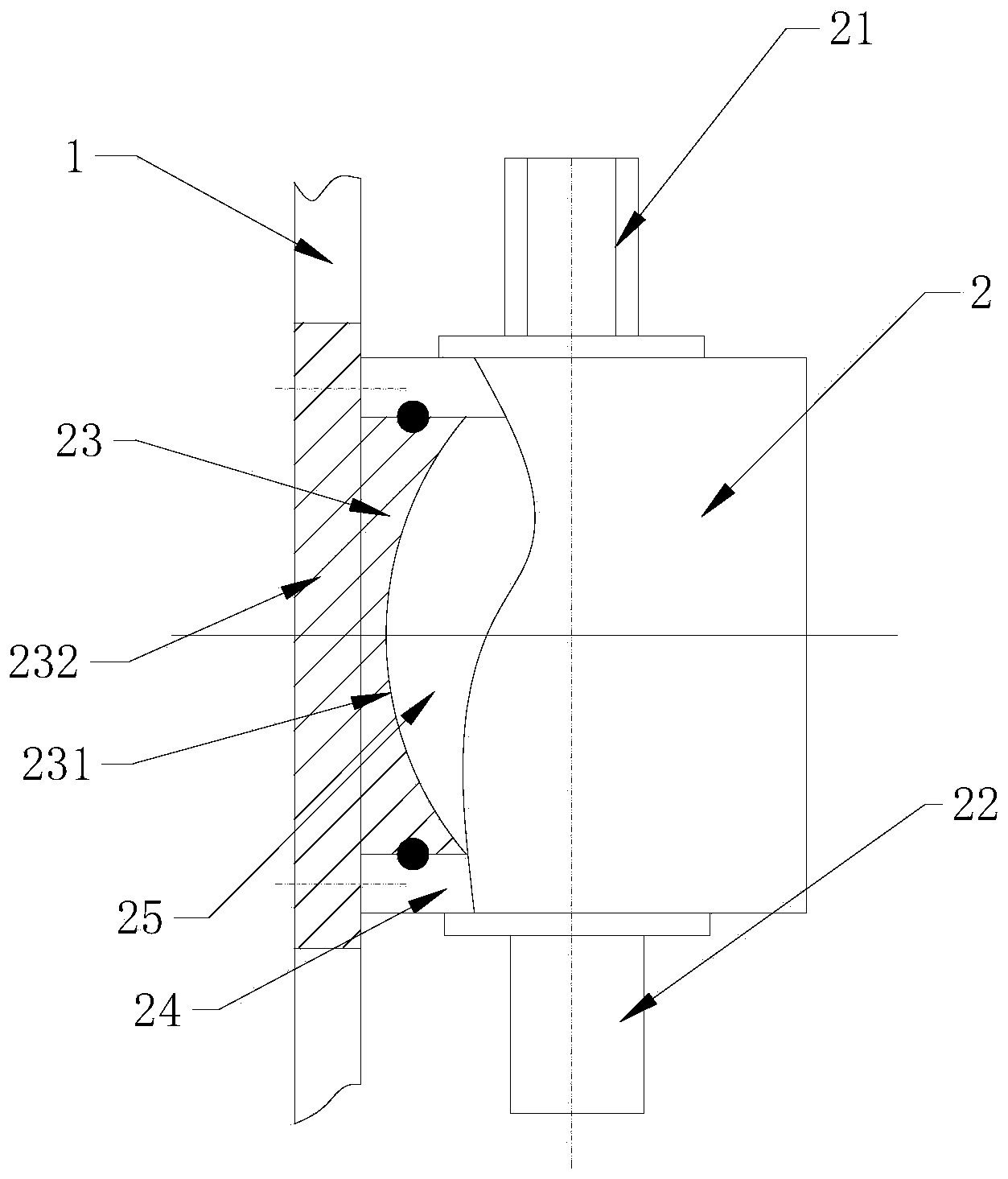

[0022] The laser dust concentration sensor is fixed in the casing, the laser dust concentration sensor includes a casing, a laser light source, a photoelectric detector and a spherical mirror, the casing is fixed in the casing, and a dust concentration detection chamber is arranged in the casing, The housing is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com