Ultrasonic inspection method, ultrasonic inspection device and integrated longitudinal wave, transverse wave and creeping wave ultrasonic angle beam probe

A technology of ultrasonic and oblique probes, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis and measuring devices using sound waves/ultrasonic waves/infrasonic waves. , to achieve the effect of improving flaw detection efficiency, improving accuracy and reducing missed detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Such as Figure 19 A method of ultrasonic flaw detection shown, comprising the following steps:

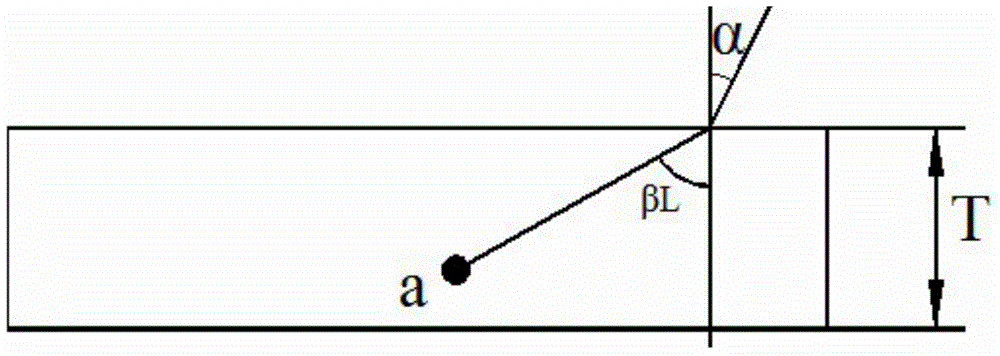

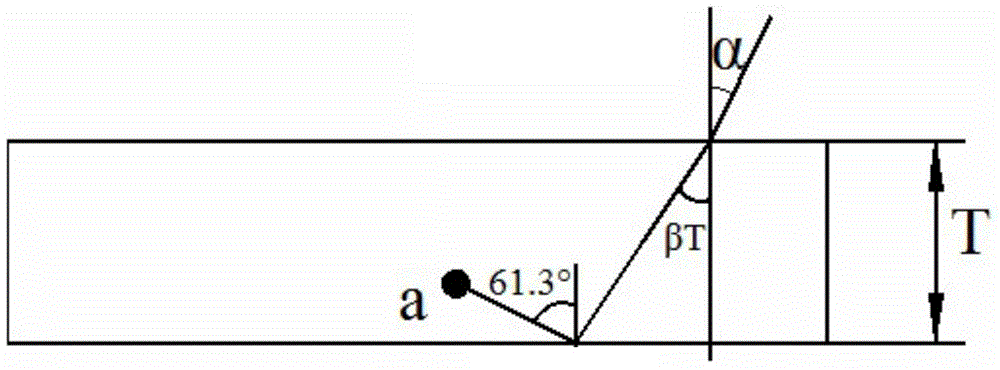

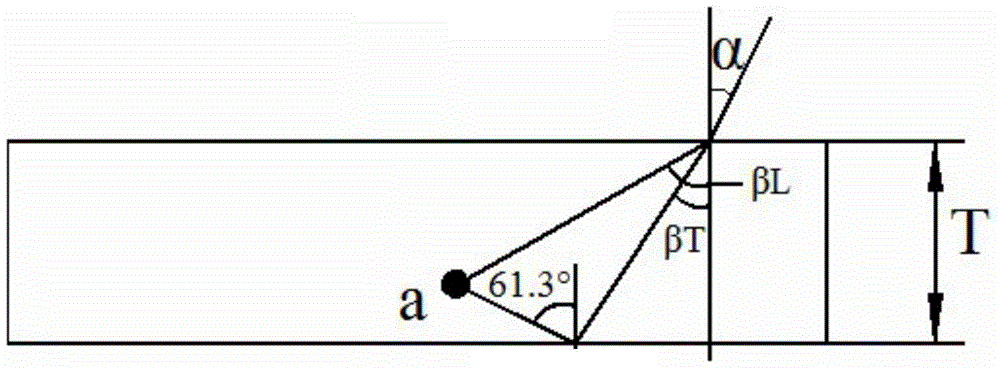

[0070]Step 1: Prepare an ultrasonic oblique probe with an incident angle of α, a longitudinal wave refraction angle of βL, and a shear wave refraction angle of βT. , and the speed of sound of the longitudinal wave and the shear wave in the second medium, combined with the preset condition that the refraction angle of the longitudinal wave and the refraction angle of the shear wave are complementary angles to each other to determine;

[0071] Step 2: Adjust the ultrasonic oblique probe;

[0072] Step 3: disposing the ultrasonic oblique probe on the outer surface of the workpiece to be inspected;

[0073] Step 4: sending out an ultrasonic beam from the ultrasonic oblique probe for flaw detection of the workpiece to be inspected;

[0074] Step 5: Judging whether the workpiece to be inspected has a defect and the corresponding defect position according to the reflected echo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com