Semiconductor porcelain plate sand blasting machine

A sandblasting machine, semiconductor technology, applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve tinnitus and other problems, and achieve the effect of a good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

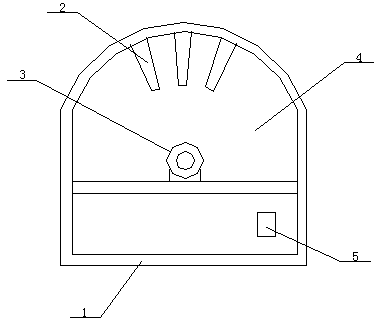

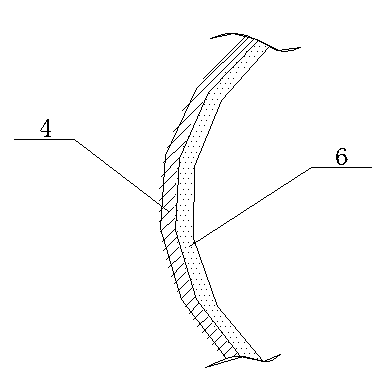

[0011] see figure 1 , figure 2 , the specific embodiment adopts the following technical solutions: it includes frame 1, spray gun 2, turntable 3, anti-skid cover 4, spray gun switch 5, several spray guns 2 are arranged on the inner wall of the upper end of frame 1, and several spray guns 2 In the same orientation, a turntable 3 is provided inside the frame 1, and the turntable 3 is arranged in the direction of several spray guns 2. A dust cover 4 for preventing mortar from flying is provided on the frame 1. The lower end of the dust cover 4 is set A spray gun switch 5 is provided, and a sound-absorbing material layer 6 is also arranged on the inner wall of the dust cover 4 .

[0012] The sound-absorbing material layer 6 is slag wool.

[0013] In this specific embodiment, when sandblasting, the semiconductor device to be sprayed is placed on the turntable 3, the spray gun switch 5 is turned on, the mortar is ejected from several spray guns 2, and the turntable 3 is rotated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com