A temperature self-monitoring ball bearing

A self-monitoring, ball bearing technology, applied in the direction of bearing components, shafts and bearings, bearing assembly, etc., can solve the problem of difficulty in obtaining the running state of the bearing in a timely and accurate manner, and achieve reasonable determination of configuration parameters, strong power generation capability, and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

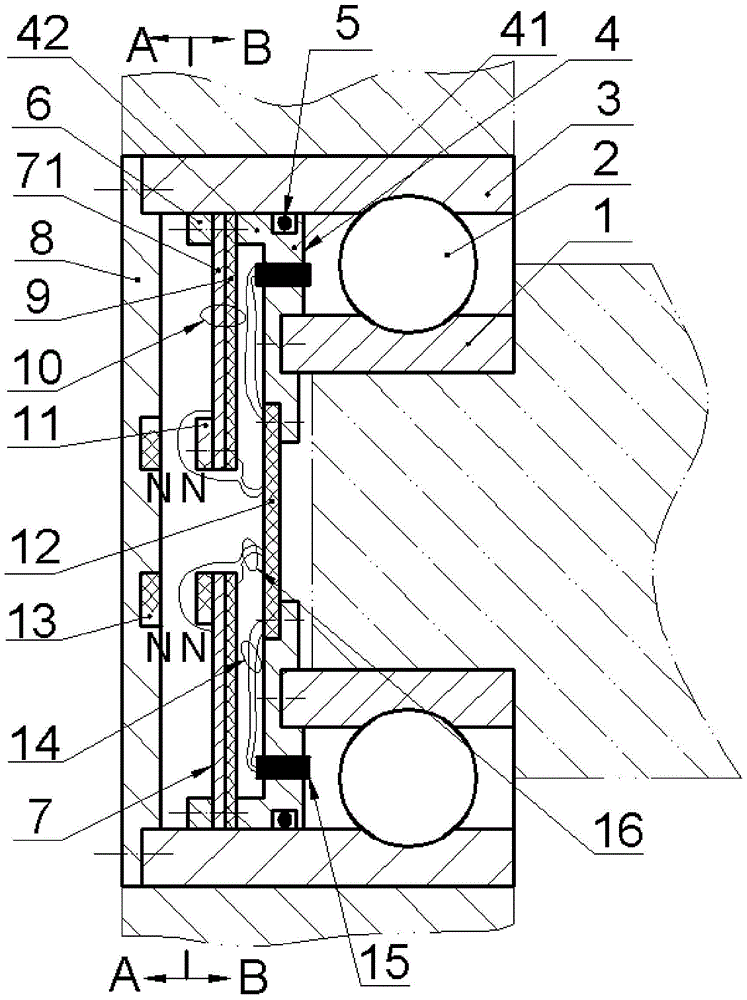

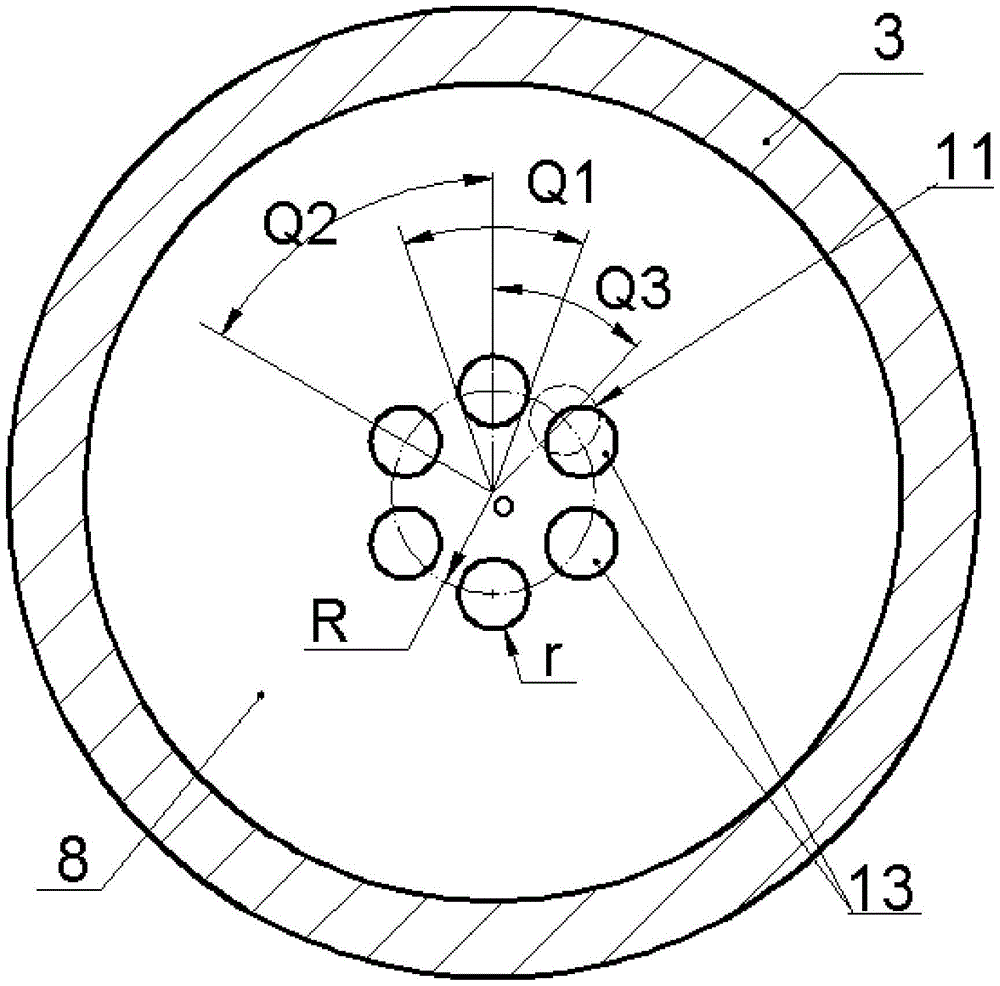

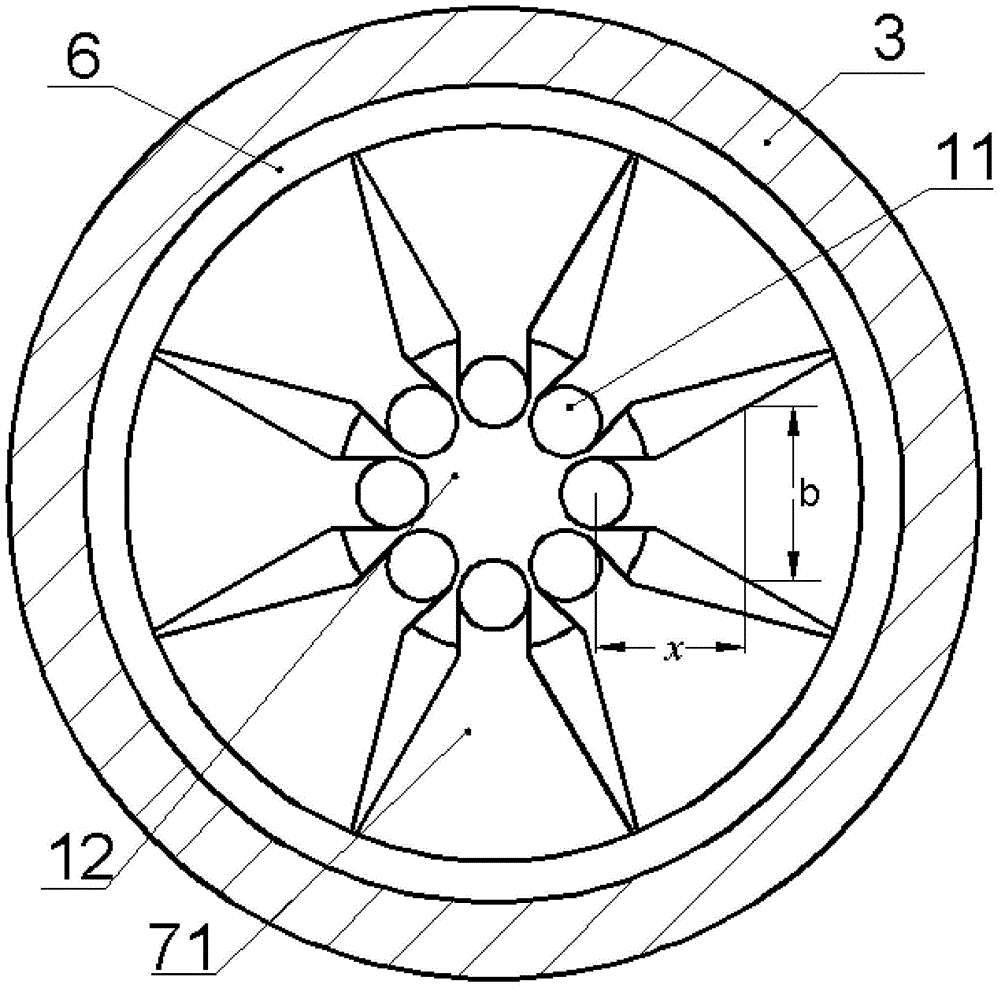

[0014] Such as Figure 1 to Figure 4 As shown, it includes the inner ring 1, the ball 2, the outer ring 3, the width of the outer ring 3 is greater than the width of the inner ring 1, and the inner ring 1 and the side of the outer ring 3 are aligned and installed; On the side, the end face of the inner ring 1 is fixed with a mounting tube 4 by screws, the end face of the outer ring 3 is fixed with an excitation disc 8, the excitation disc 8 is evenly inlaid with excitation magnets 13, and the bottom plate 41 of the installation tube 4 is installed with a circuit board 12 And the sensor 15, the end surface of the side wall 42 of the installation cylinder 4 is crimped with a metal film 7 through the screw and the pressure ring 6, and the O-ring 5 is installed between the outer surface of the side wall 42 of the installation cylinder 4 and the inner surface of the outer ring 3 , the metal film 7 is provided with a cantilever beam 71, the side of the free end of the cantilever bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com