Production process device for rebar with ribs at three sides

A threaded steel bar and production process technology, which is applied in the field of iron and steel metallurgy, can solve the problems of low strength level of steel bars, loose bonding, hidden dangers of building safety, etc., and achieve the effect of large rolling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

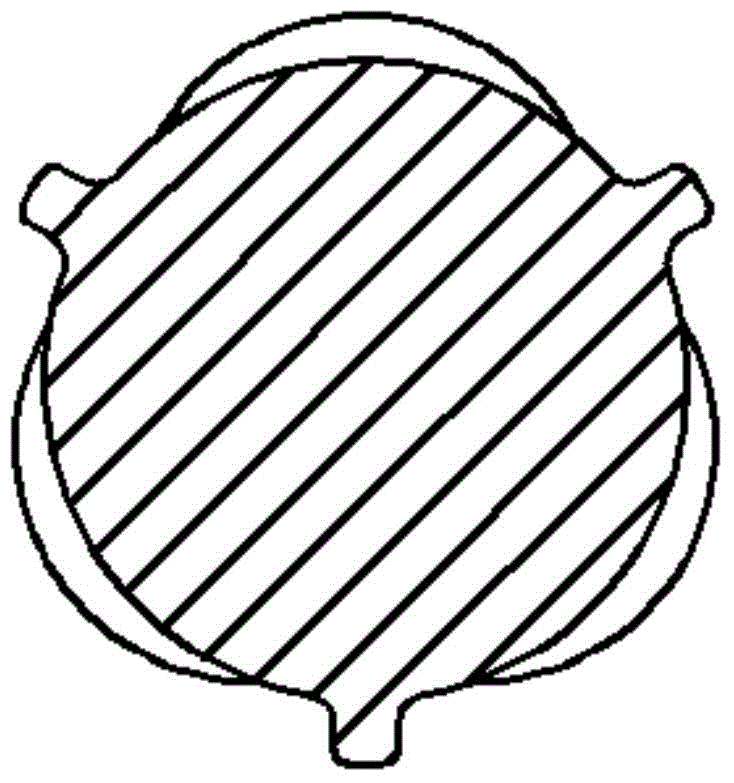

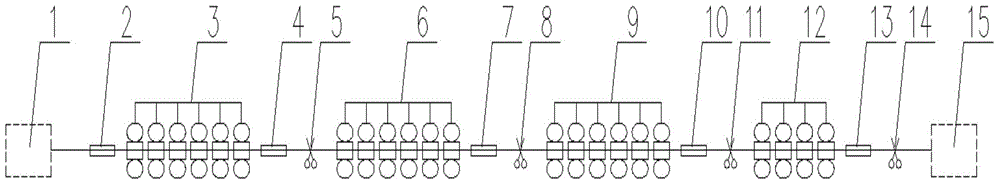

[0019] As shown in the figure, a production process layout of ribbed rebar on three sides includes pre-processing steps 1, roughing mill 3, first shearing equipment 5, intermediate rolling mill 6, and second shearing equipment 8 in sequence. , Finishing mill 9, third shearing equipment 11, reducing and sizing mill 12, fourth shearing equipment 14, and post-processing process 15, the rough rolling mill, intermediate rolling mill, finishing mill and reducing sizing mill are all A high-strength three-high rolling mill is adopted, and the roll surface of the last three-high rolling mill of the finishing mill is engraved with crescent-shaped rib grooves that match the shape of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com