Automatic stamping machine

A stamping machine and automatic technology, applied in the field of stamping machines, can solve the problems of high space requirements, large size of the stamping device, and reduced size, and achieve the effect of reducing the size, increasing the flexibility of use, and reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

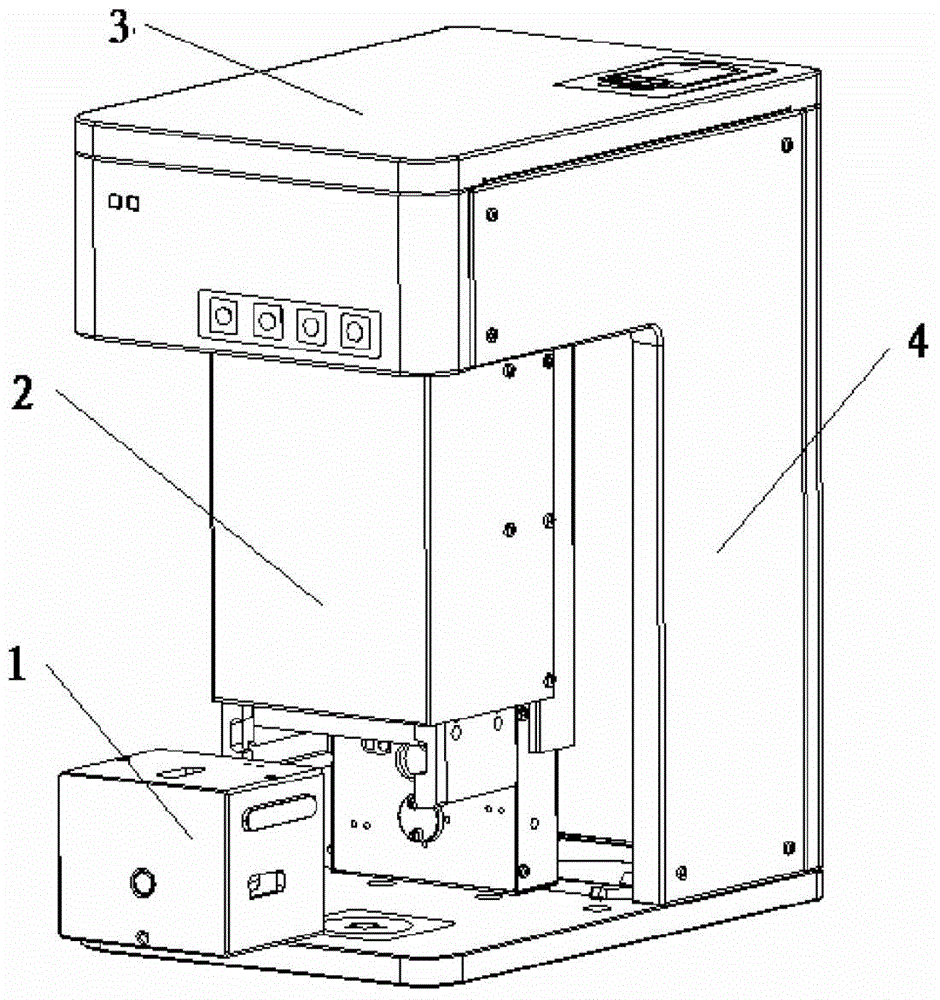

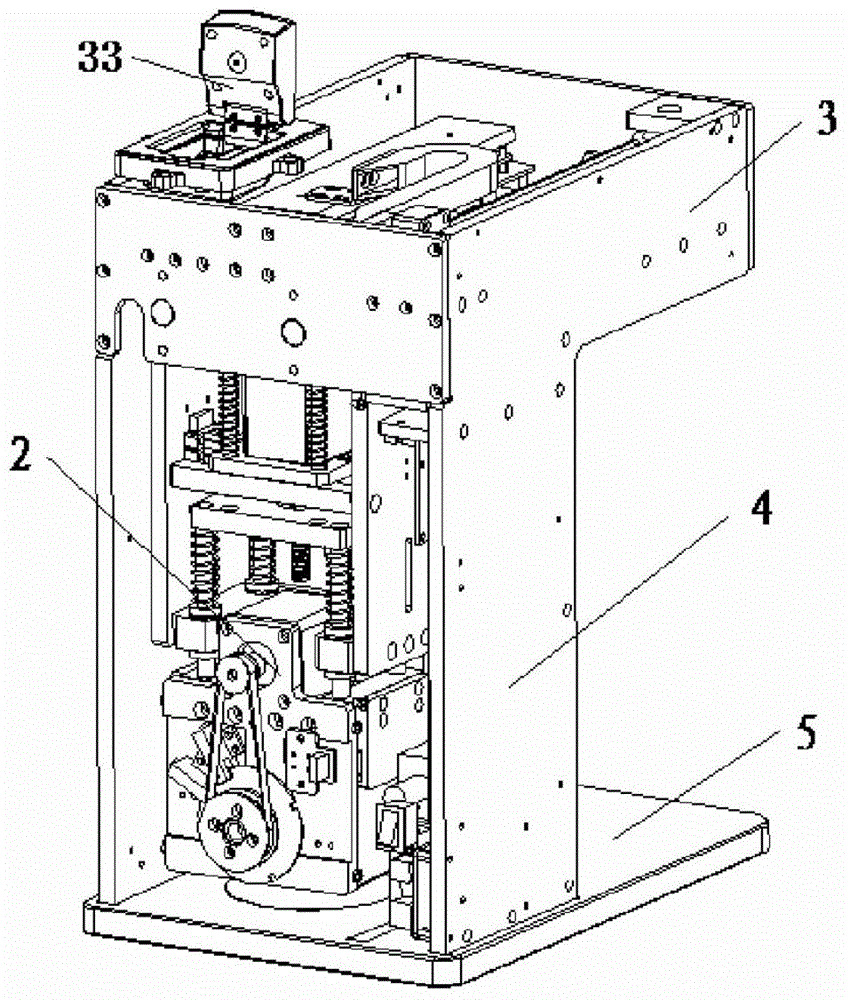

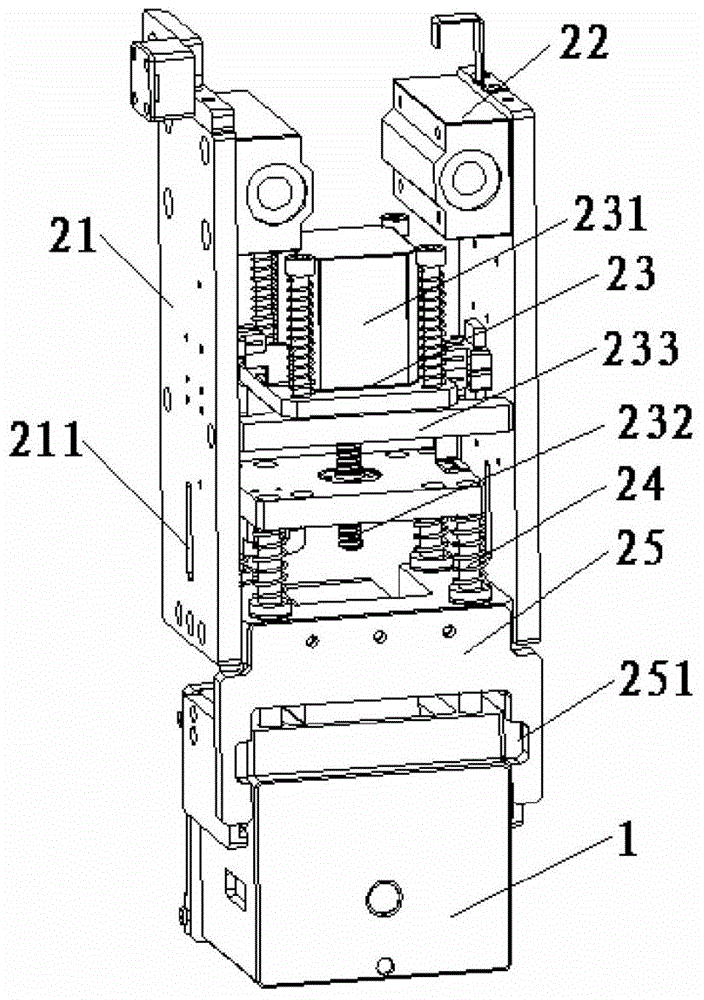

[0051] as attached figure 1 And attached figure 2 As shown, a schematic diagram of the overall structure of a kind of automatic stamp machine provided by a preferred embodiment of the present invention, including a stamp machine body and a stamp module 1 installed on the stamp machine body; Stamping platform 5, a support frame 4 extending upward along one side of the stamping platform 5 perpendicular to the plane where the stamping platform 5 is located, and a detection mechanism 3 extending parallel to the stamping platform 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com