Trapping device and trapping method suitable for smoke released by tobacco material at heating non-burning state

A heating, non-combustion, and flue gas trapping technology, applied in the field of tobacco, can solve the problems of unsatisfactory flue gas release performance and flue gas sensory quality, and achieve the effects of simple and reasonable trapping device and stable parameter control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

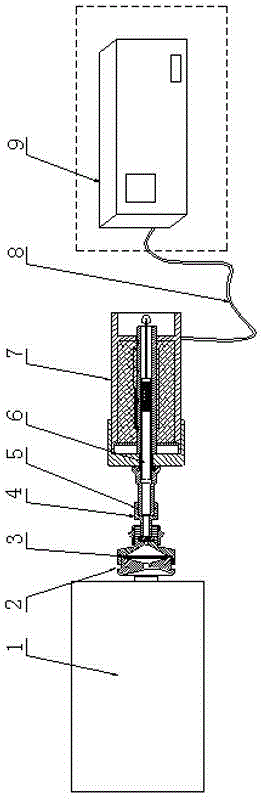

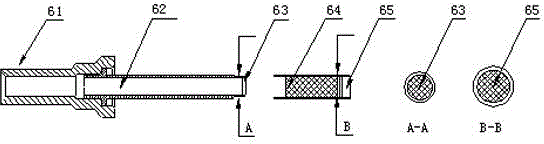

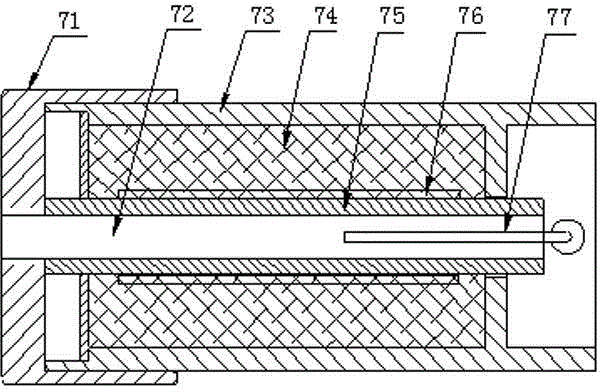

Image

Examples

Embodiment 1

[0031] Weigh an appropriate amount of shredded tobacco, fill it in the filling chamber of the suction pipe, and set the heating temperature to 200, 300, and 400° C. respectively. Canadian deep smoking mode (suction volume 50mL, suction time 2s, suction cycle 30s) and ISO suction mode (suction volume 35mL, suction time 2s, suction cycle 60s) were adopted respectively, and the The smoke pipes are used for smoking, each smokes 10 puffs, and the smoke particles produced by the 3 pipes are collected on a Cambridge filter. Five puffs were performed for each heating temperature. The analysis of total particulate matter in the flue gas from five puffs at different heating temperatures was carried out using standard methods. The analysis results are shown in the table below. It can be seen that the method of the present invention has good stability at different temperatures and different suction modes.

[0032] surface Total particulate matter in smoke under different temperature ...

Embodiment 2

[0035] Weigh an appropriate amount of shredded tobacco, fill it in the filling chamber of the suction pipe, and set the heating temperature to 200, 250, 300, 350, and 400°C, respectively. The Canadian deep smoking mode is adopted, that is, the suction volume is 50mL, the suction time is 2s, and the suction cycle is 30s. The particulate phase is captured on a Cambridge filter disc. Standard methods were used to analyze the total particulate matter, moisture, nicotine, and tar in the flue gas at different heating temperatures. The analysis results are shown in Table 2 below.

[0036] temperature / ℃ total particulate matter moisture Nicotine tar 200 20.3 10.1 1.3 8.9 250 28.2 13.3 1.8 13.0 300 31.2 14.9 1.8 14.5 350 33.7 13.4 1.5 18.8 400 37.5 13.6 1.3 19.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com