A rotary flapping wing aircraft

A flapping-wing aircraft and left-rotating technology, applied in the field of aircraft, can solve the problems of poor maneuverability, low efficiency, and high fatigue strength requirements of flapping wings, and achieve the effect of strong maneuverability and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

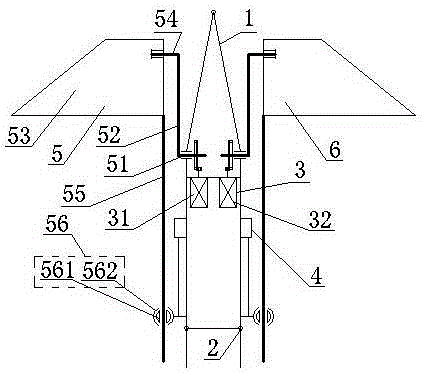

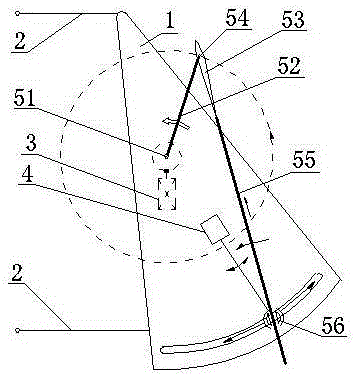

[0013] now attached figure 1 And attached figure 2 The present invention is described with an example: a rotary flapping wing aircraft includes a fuselage 1 , a landing gear 2 , a power system 3 and a control system 4 . Power system 3 includes left engine 31 and its speed regulating device, right engine 32 and its speed regulating device, left rotating flapping wing 5 and right rotating flapping wing 6; control system 4 includes engine control system and flight attitude control system; The wing 5 and the right-rotating flapping wing 6 have the same structure, and they are respectively symmetrically arranged on the left and right sides of the fuselage 1. The left-rotating flapping wing 5 is driven by the left engine 31, and the right-rotating flapping wing 6 is driven by the right engine 32; the left engine 31 and the Right motor 32 structures and parameters are all identical, and their gear reducer and speed regulating device are also identical. The aircraft can lift and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com