A rotary flapping-driven aircraft

An aircraft, left-rotation technology, applied in the field of aircraft, can solve the problems of low efficiency, difficulty in taking off and landing at short distances, and high requirements on the fatigue strength of flapping wings, and achieves the effect of high efficiency and convenient short-distance take-off and landing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

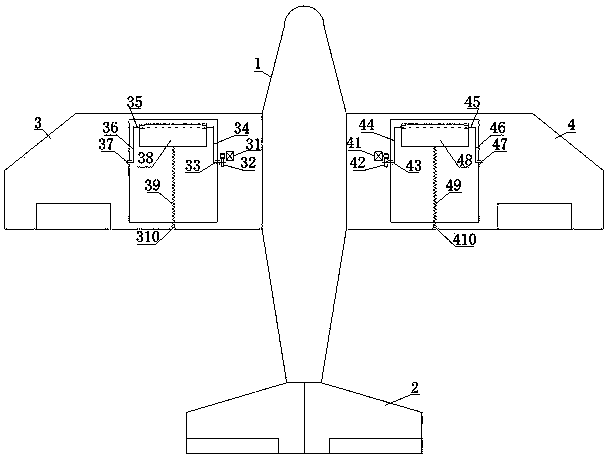

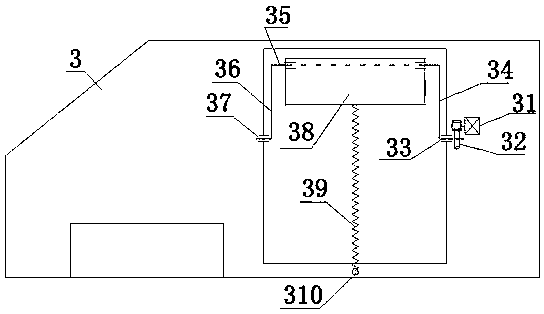

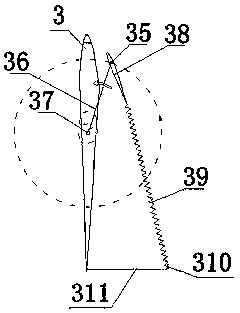

[0013] now attached figure 1 , attached figure 2 And attached image 3 The present invention is described by way of example: a kind of rotary flapping wing driving aircraft is made up of fuselage 1, landing gear, empennage 2, left wing 3, right wing 4 and control system. The left wing 3 and the right wing 4 have the same structure, and are arranged symmetrically on the left and right sides of the fuselage 1; the middle part of the left wing 3 has a rectangular hole in which a left-rotating flapping wing device is installed; the right wing 4 The same rectangular hole is also arranged in the middle part, and a symmetrical right-rotating flapping-wing device with the same structure as the left-rotating flapping-wing device is installed in this hole. The left-rotating flapping-wing device and the right-rotating flapping-wing device are independently driven by respective engines to provide thrust for the aircraft. The aircraft has high efficiency, is convenient for short-distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com