Cylinder type molded pulp package sizing device

A technology of pulp molding and setting device, which is applied in the direction of textiles and paper making, can solve the problems of difficulty in mold removal and low heating efficiency, and achieve the effects of shortening drying time, prolonging service life and facilitating mold removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

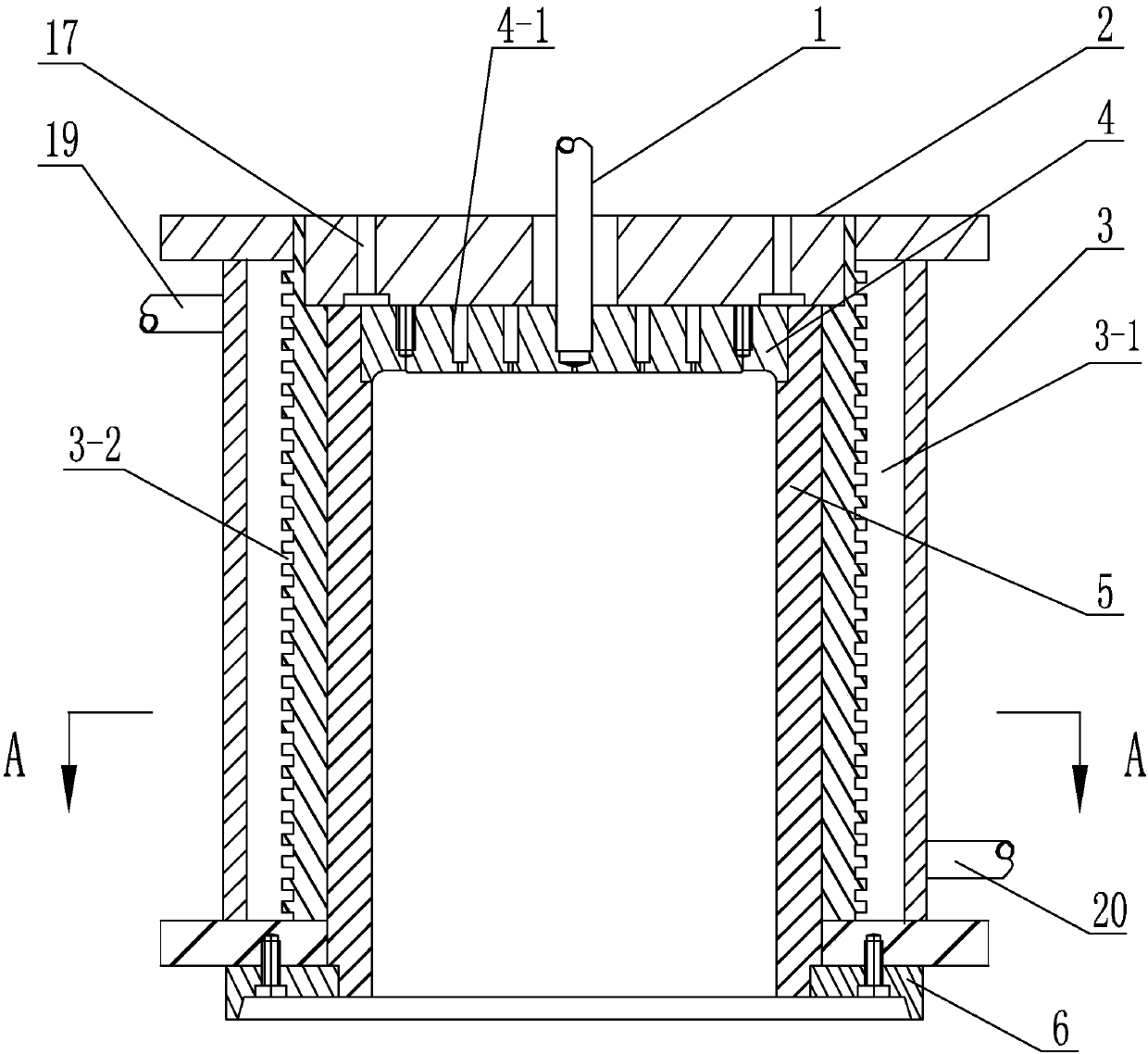

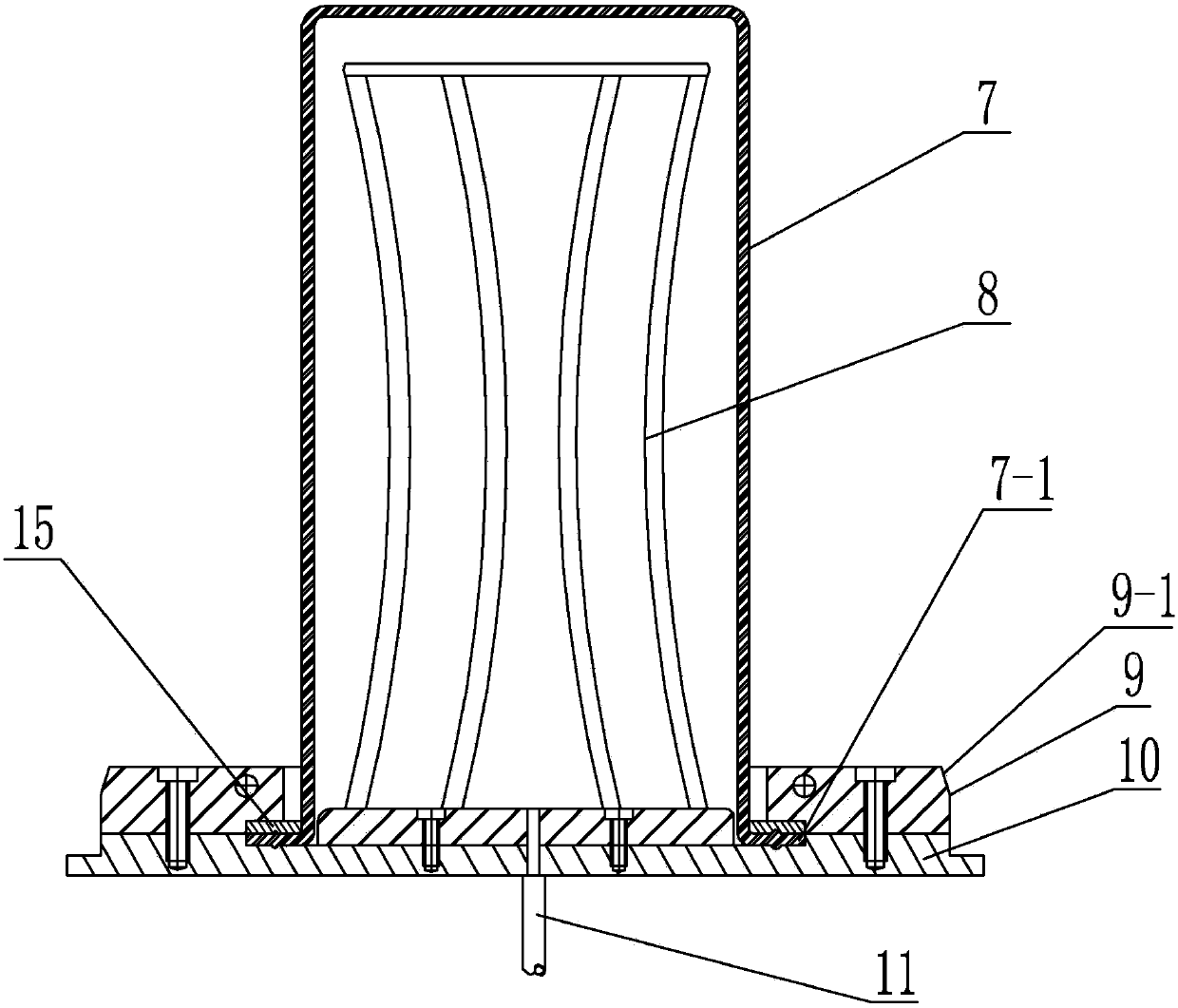

[0012] Specific implementation mode one: as Figure 1~4 As shown, the straight tube type pulp molding packaging shaping device of this embodiment includes an upper mold and a lower mold, the lower mold is located in the upper mold and the two are coaxially arranged; 3, bottom mold 4, mold cylinder 5 and positioning ring 6, heat conduction oil heater 3 is set on the outer wall of mold cylinder 5, heat conduction oil heater 3 is provided with annular heat conduction oil cavity 3-1 along the circumferential direction, close to the mold The wall surface of the heat-conducting oil chamber 3-1 of the cylinder 5 is provided with several annular grooves 3-2 in sequence from top to bottom. The upper part is provided with a heat transfer oil outlet 19; the bottom mold 4 is installed on the upper end of the mold cylinder 5, the upper end cover 2 is arranged on the upper end surface of the bottom mold 4, the positioning ring 6 is fixedly sleeved on the lower end of the mold cylinder 5, an...

specific Embodiment approach 2

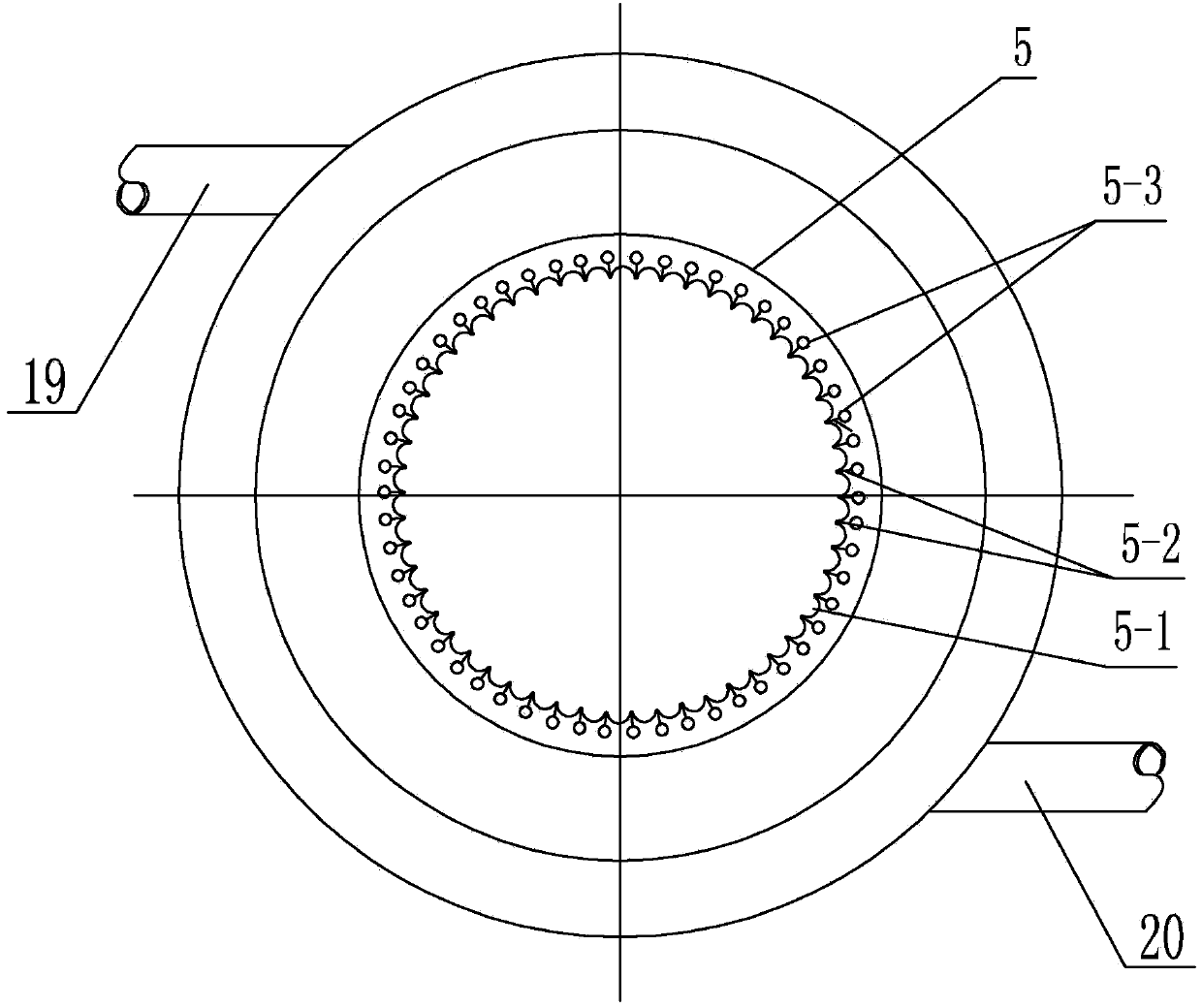

[0014] Specific implementation mode two: as image 3 As shown, the inner wall of the mold cylinder 5 in this embodiment is processed with several vertical arc-shaped grooves 5-1 along the circumferential direction. Such setting, compared with the existing smooth surface, greatly increases the compressive strength of the surface of the molded product. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: as image 3 As shown, in this embodiment, a slit 5-2 is provided along the vertical direction at the junction of two adjacent vertical arc-shaped grooves 5-1, and several vertical exhaust vents are processed on the mold barrel 5 along the circumferential direction. Holes 5-3, the number of slits 5-2 are set in accordance with the number of vertical exhaust through holes 5-3, each slit 5-2 communicates with a corresponding vertical exhaust through hole 5-3, each The upper ends of each vertical exhaust through-hole 5-3 are communicated with the second exhaust through-hole 17. This design facilitates the water vapor generated during the production of pulp molded products to be discharged through the slit 5-2, the vertical exhaust through hole 5-3, and the second exhaust through hole 17 in time. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com