Large-rotation high-speed punching progressive die of multi-column electric motor stator

A motor stator, high-speed technology, applied in the field of multi-row motor stator large-turn high-speed punching and grading molds, can solve the problems of poor parallelism of iron cores, uneven thickness of raw materials, large differences, etc., to improve product quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

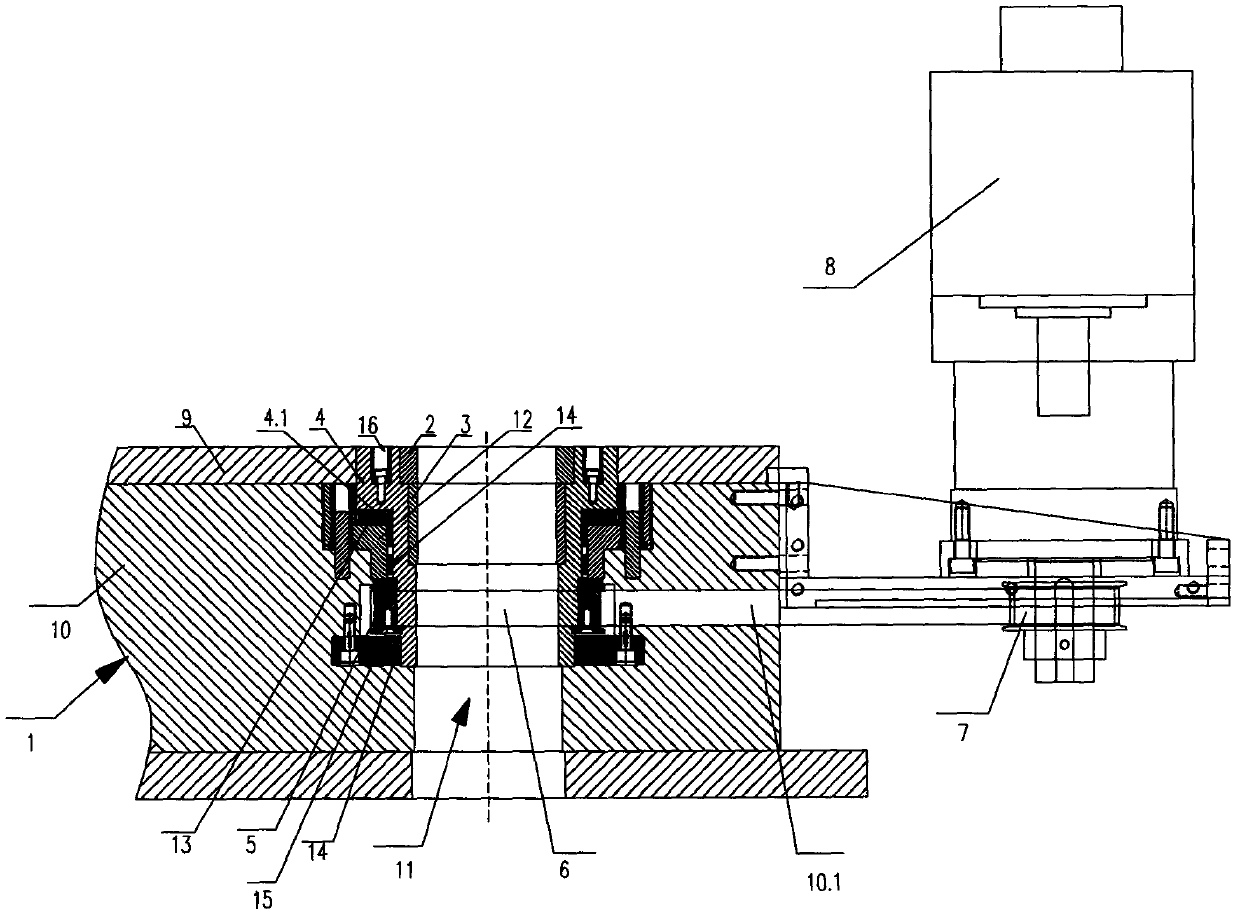

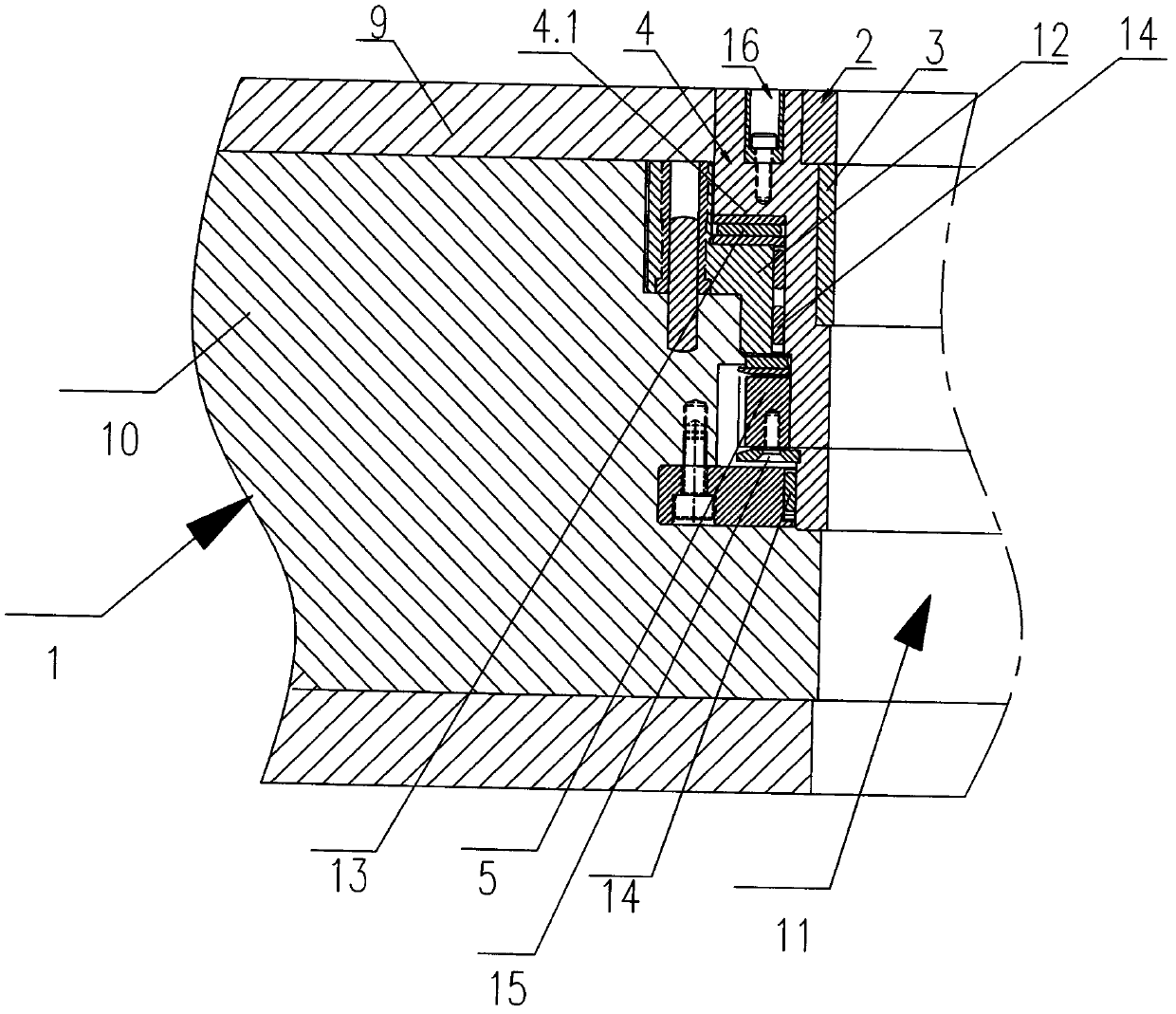

[0030] refer to figure 1 and figure 2 As shown, a multi-row motor stator large-rotation high-speed punching progressive die includes an upper die, a lower die 1, and other common features of existing progressive dies, such as multi-step stamping components, so it will not be described in detail here. This embodiment mainly describes the innovations of the present invention, and the present invention also includes a blanking die 2, a locking ring 3, a twist sleeve 4, a first synchronous wheel 5, a synchronous belt 6, a second synchronous wheel 7 and a servo motor 8, The lower mold 1 includes the concave template 9 and the lower mold base 10 from top to bottom. To limit and rotate in the circumferential direction; the blanking die 2 and the locking ring 3 are tightly fitted in the upper port of the twist sleeve 4, the locking ring 3 is located below the blanking die 2, and the inner diameter of the locking ring 3 is smaller than the blanking die The inner diameter of the die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com