Ejection device of numerically controlled lathe

A technology of a jacking device and a numerically controlled lathe, which is applied in the field of machining, can solve the problems of difficult control of the parallelism between the end face of the workpiece and the reference plane, and the existence of a certain level, and the parallelism is difficult to meet the technical requirements, so as to control product quality and improve processing. Accuracy, the effect of solving the parallelism excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

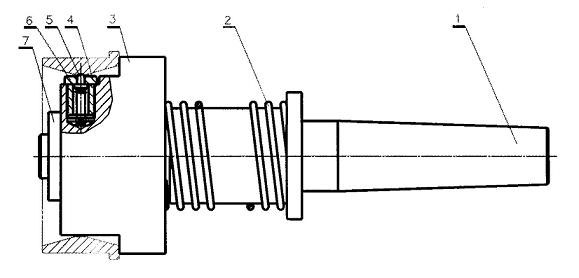

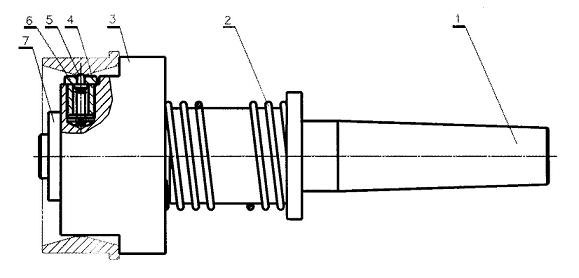

[0010] Such as figure 1 As shown, the CNC lathe jacking device of the present invention is mainly composed of a mandrel 1, a spring 2, a positioning body 3, a nut 4, a stop pin 5, a spring 6, and a nut 7. The mandrel 1 is the main body of the device and supports Function, the positioning body 3 can move axially on the mandrel 1, and the axial limit is carried out by the nut 7 and the spring 2. The limit pins 5 are located in the positioning body and are distributed in a 120° circle (as shown in Figure 2). Each limit pin Controlled by the spring 6, it can move radially, and the workpiece is fixed on the three-point positioning pin. This CNC lathe jacking device uses the hydraulic tailstock top system of the CNC lathe to study feeding and jacking, so that the jaws are in the clamping process. , to fully ensure that the positioning surface of the workpiece to be processed is fully in contact with the positioning surface of the fixture, the ejector device fixes the mandrel 1 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com