A positioning device for visual inspection equipment

A technology for visual inspection and positioning device, which is applied to workpiece clamping devices, manufacturing tools, etc., and can solve problems such as visible defects in cylinder blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

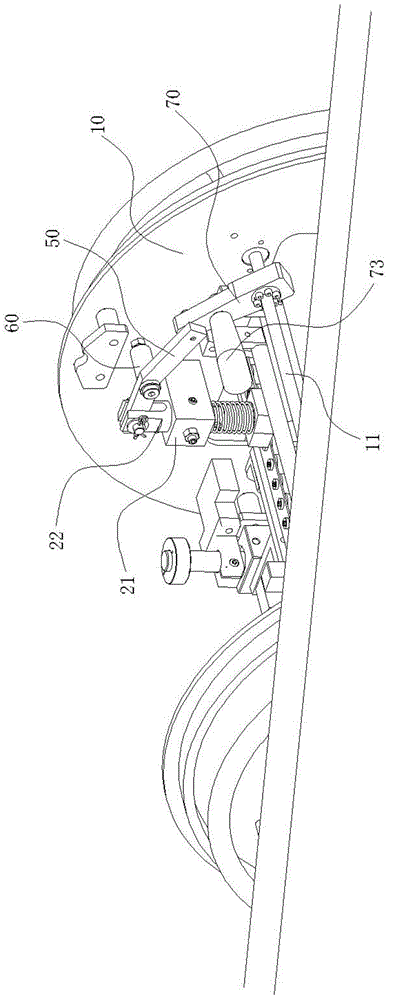

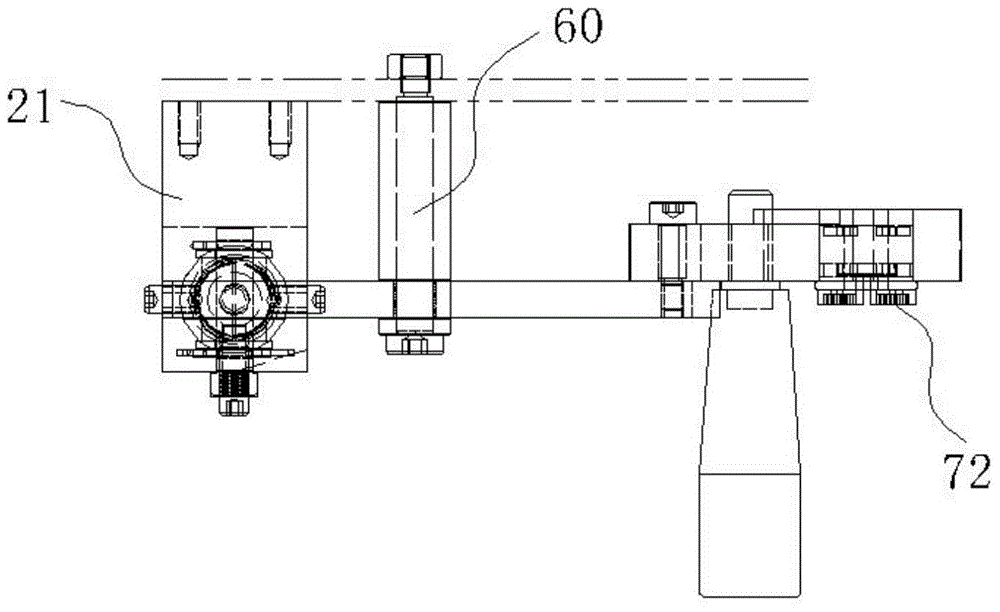

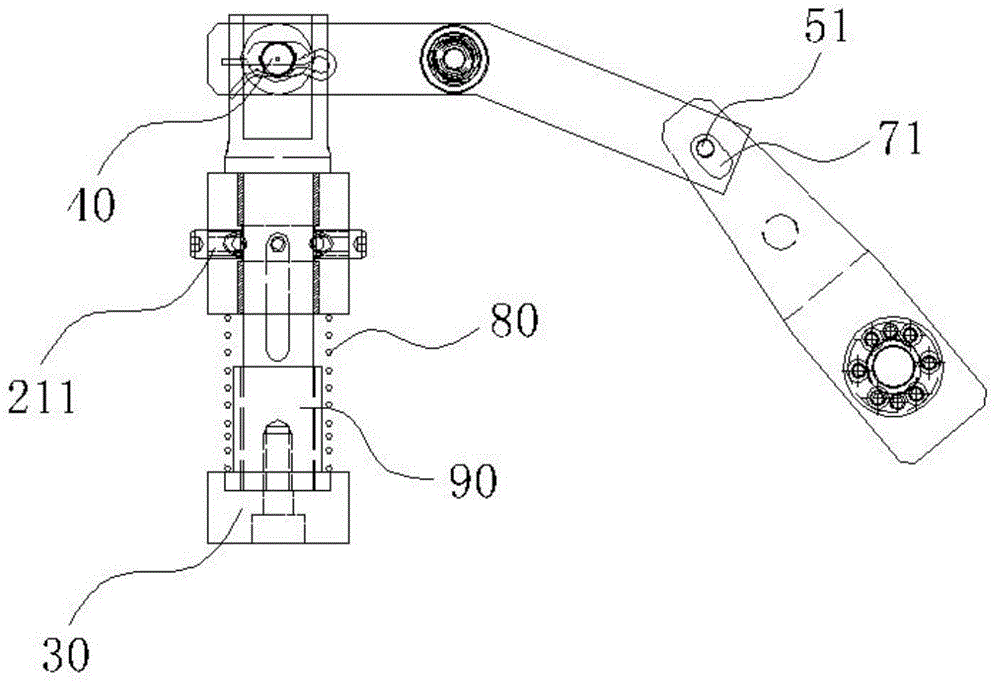

[0025] Such as Figure 1 to Figure 3 As shown, a positioning device for visual inspection equipment includes a shaft seat 21 fixed on the main body 10 of the visual inspection device, a first shaft 22 used in conjunction with the shaft seat 21, a positioning block 30 installed at one end of the first shaft 22, The first hinge pin 40 installed on the other end of the shaft 22 and the V-shaped block 50 connected with the first hinge pin 40 .

[0026] The shaft seat 21 is equipped with a ball plunger 211, a spring 80 and a metal collar 90 are arranged between the shaft seat 21 and the positioning block 30, and the second shaft 22 is connected between the ball plunger 211, the spring 80 and the metal shaft. Under the action of the ring 90, it can reciprocate in the axial direction.

[0027] A second hinge pin 60 is arranged in the middle of the V-shaped block 50 , and the second hinge pin 60 is fixed on the main body 10 of the visual inspection equipment, and the V-shaped block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com