A combined anti-buckling energy-dissipating support

A buckling-proof energy-consuming and combined technology, applied in earthquake-proofing, building components and other directions, can solve the problems of large amount of material, lowering of buckling-proof and energy-consuming support economy and technological difficulty, and failure to meet building requirements, so as to save materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

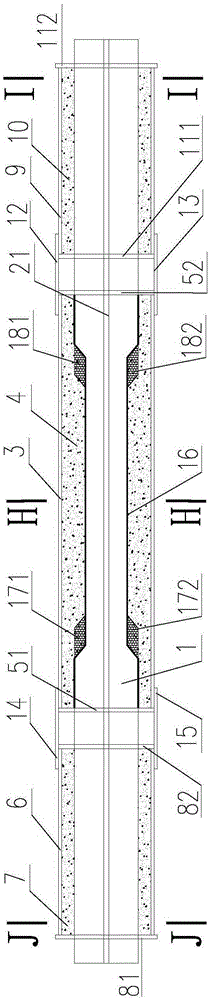

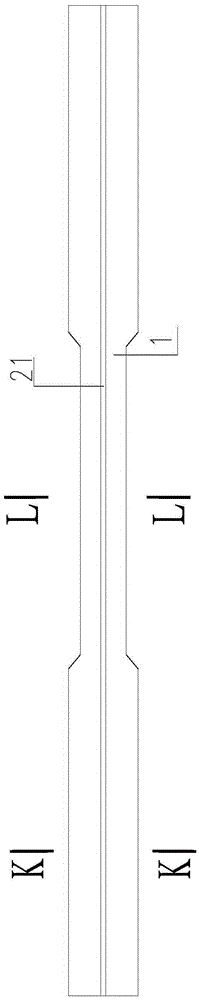

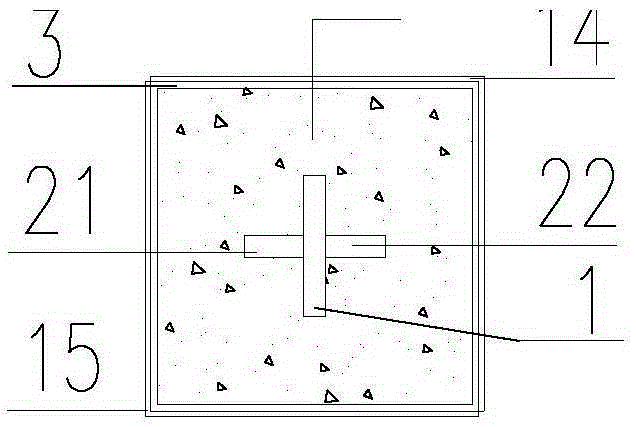

[0042] Reference Figure 1 ~ Figure 7 , A combined anti-buckling energy dissipation support, including a core force member and a restraining member. The core force member includes a main core force member 1, a first secondary core force member 21 and a second secondary core force member 22, Both ends of the core force-bearing member are respectively provided with a reinforced structural section, which is called the front non-yielding transformation section and the rear non-yielding transformation section. The constraining member includes a yield section restraint device for restraining the main core force member 1, and The left restraint device for the front non-yielding transformation section, and the right restraint device for restraining the rear non-yielding transformation section. The yielding section restraint device includes an intermediate sleeve 3, a grouting material 4, and an end plate. The intermediate sleeve 3 is sleeved on the periphery of the main core stress memb...

Embodiment 2

[0055] Reference Figure 8~Figure 16 In this embodiment, all the force-receiving members are divided into three sections.

[0056] See Figure 8 As shown, the main core force member, the first secondary core force member, and the second secondary core force member of this embodiment are divided into three sections respectively. The main core force member consists of the main connecting plate 25 and the left main connecting plate. 116 and the right main connecting plate 18; the first auxiliary core force member is composed of the first auxiliary connecting plate 211, the first left auxiliary connecting plate 171 and the first right auxiliary connecting plate 191. The second auxiliary core force member is composed of the first The second auxiliary connecting plate 212, the second left auxiliary connecting plate 172 and the second right auxiliary connecting plate 192 are composed. The outer surface of the main connecting plate 25 is provided with a non-adhesive material layer 16.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com