Flow guiding pipeline guiding fluid to spirally go forwards

A pipeline and fluid technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of difficult to achieve ventilation effect, difficult to control the air flow, occupying space, etc., to achieve the effect of increasing the maximum air supply speed, occupying less space, and convenient manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

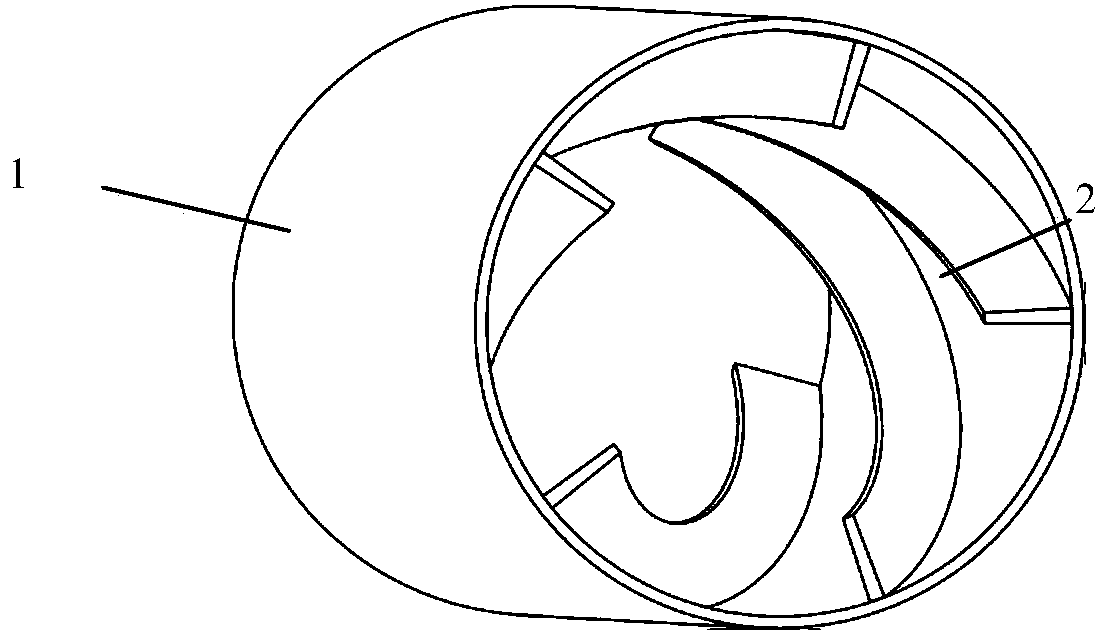

[0018] Such as figure 1 As shown, it is a diversion pipe that guides the fluid to screw in. The pipe body of the pipe is injection molded by PVC material. The inner diameter of the pipe is 100mm and the length is 300mm. The thickness of the pipe wall and the thickness of the fins can be determined according to the actual situation. The helical fins are injection molded together with the pipe. The height of the spiral fins is not less than 10% of the inner diameter of the tube. The number and length of the spiral fins can be determined according to the actual situation. The spiral fins are evenly arranged around the tube wall. The helix angle of the helical fin (the angle between the tangent of the helix and the axis) is not greater than 25°, and the number of turns of a single helical fin around the axis is within three circles. The guide pipe is connected with the air outlet of the blower to optimize the air flow out of the blower.

Embodiment 2

[0020] The difference between the present embodiment and the first embodiment is that the pipeline is divided into two parts: the tube body and the fins. The pipe body is injection molded by PVC material. The inner diameter of the pipe is 100mm and the length is 300mm. The thickness of the pipe wall can be determined according to the actual situation. It is injection molded together with the pipe body. The fin material is made of flexible metal sheet, and the spiral fin is formed by inserting the metal sheet into the groove during installation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com