Vehicle Load Measuring Displacement Sensors

A displacement sensor and vehicle technology, applied in the field of sensing, can solve the problems of heavy load, crushed installation structure, bumpy driving, etc., to achieve the effect of ensuring service life, increasing the amplitude of distance change, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

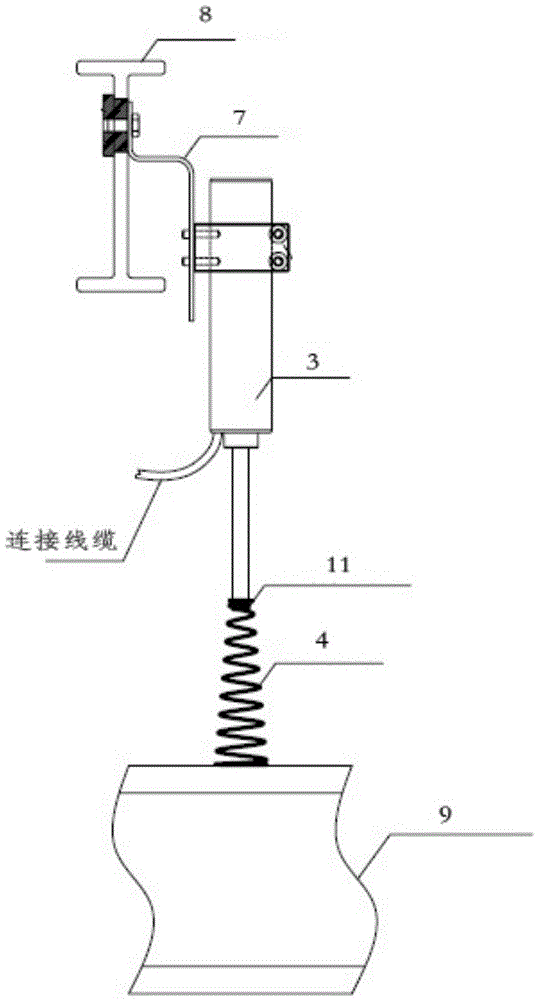

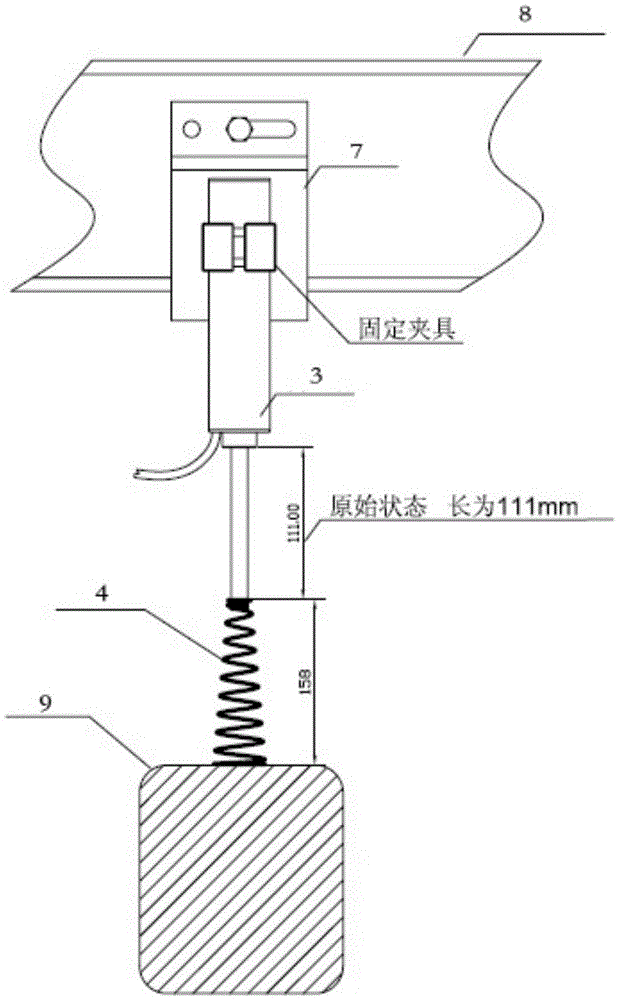

[0034] This embodiment not only provides a vehicle load-measuring displacement sensor, but also provides a corresponding installation device for the sensor, and an installation method using the above-mentioned sensor and the installation device.

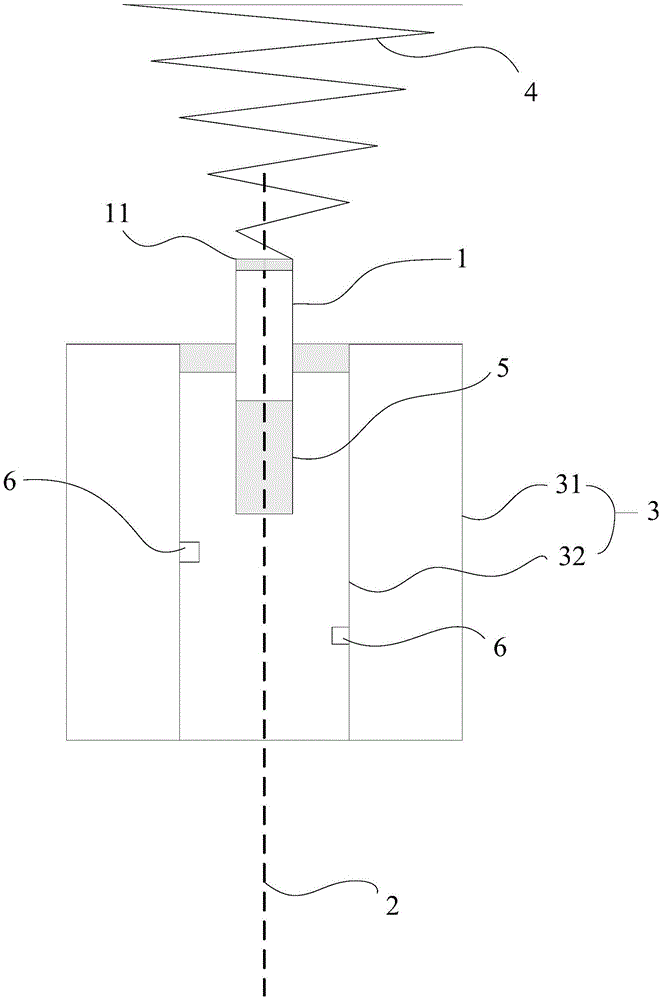

[0035] Such as figure 1 As shown, the vehicle load measurement displacement sensor of this embodiment is a magnetic induction displacement sensor, which mainly includes: a moving part 1, and a limiter 3 that is movably installed on the moving part 1 and used to limit the movement of the moving part 1 along the axial direction 2, During the relative movement between the moving part 1 and the limiting part 3, the displacement sensor will generate an indication signal for representing the load capacity of the vehicle. The end of the moving part 1 opposite to the limiting part 3 is provided with: extending away from the limiting part 3 And an elastic member 4 capable of producing deformation in the axial direction 2 . Specifically, a magn...

Embodiment 2

[0041] The main difference between this embodiment and the above-mentioned embodiments is that the elastic member 4 can also adopt cylindrical helical compression springs with the same radial size. Certainly, its recovery force is worse than that of the conical helical compression spring, but it can also achieve the purpose of the present application.

Embodiment 3

[0043] The main difference between this embodiment and the above embodiments is that the elastic member 4 can also adopt symmetrical conical helical compression springs (commonly known as waist drum springs) with different radial sizes. It has better restoring force than cylindrical helical compression spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com