A device for continuously measuring the coefficient of friction between elastic fibers

An elastic fiber and friction coefficient technology, applied in the field of devices for measuring the friction coefficient between elastic fibers, can solve the problems of unreported, large data differences, and incomparability, etc., and achieve high accuracy and accurate detection results , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

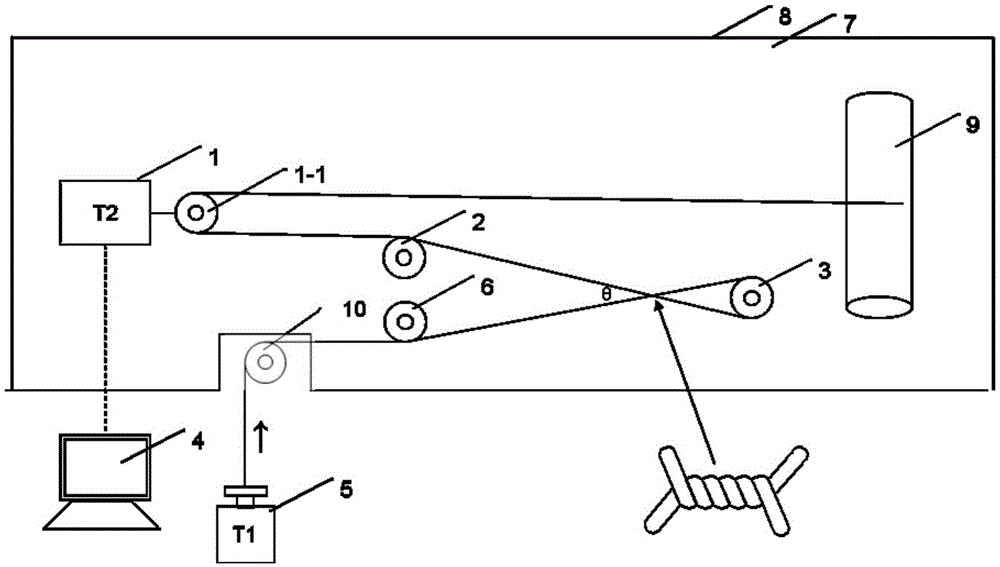

[0012] Depend on figure 1 As can be seen from the structure shown, the device includes: a tension sensor 1, a second yarn guide wheel 2, a third yarn guide wheel 3, a processor 4, a hanging load 5, a fourth yarn guide wheel 6, a panel 7, a fixed bracket 8, a roll Wrap around roller 9, steering guide wheel 10;

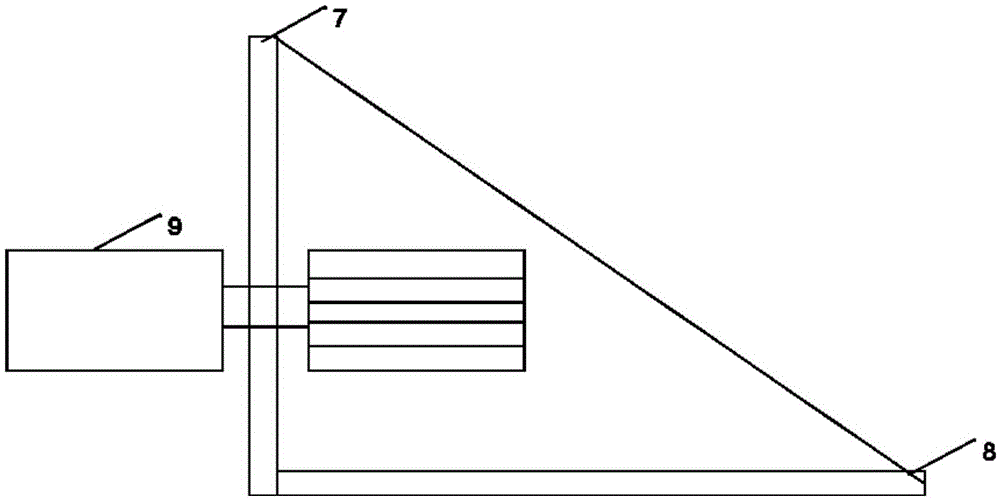

[0013] Wherein, a self-rotating winding roller 9 is located in the middle position on the far right of the panel 7, and the tension sensor 1 is located in the middle position on the leftmost side of the panel 7. The tension sensor 1 is provided with a first guide wheel 1-1, and the winding roller One side of 9 is provided with the third yarn guide wheel 3, the second yarn guide wheel 2, the fourth yarn guide wheel 6 are positioned between the first yarn guide wheel 1-1 and the third yarn guide wheel 3, and one end of the elastic fiber is fixed On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com