Calculation method of high-speed airflow friction coefficient based on strain

A technology of friction coefficient and high-speed airflow, which is applied in the field of drilling, can solve the problems of many interference factors and lack of gas-wall friction coefficient measurement methods, so as to improve accuracy, avoid the influence of empirical value of pipe wall roughness, Effects of Improving Applicability and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

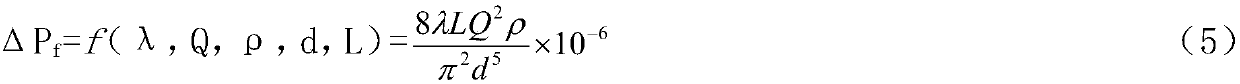

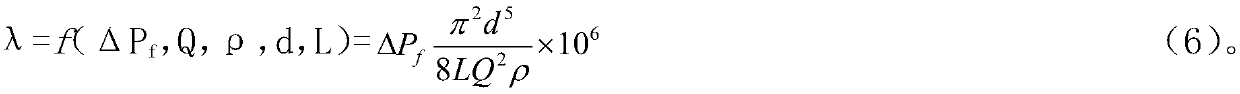

[0033] The present invention calculates the friction coefficient of the high-speed gas flow in the pipe string based on strain, that is, the present invention is mainly used for the test and calculation of the gas-wall friction coefficient in the pipe string, and the obtained friction coefficient can be further accurate for complex gas wells (three-high gas wells, reservoirs, etc.) Gas storage wells, etc.) in the pipe string to improve the applicability and reliability of the pipe string design.

[0034] The present invention is realized by the following technical solutions:

[0035] 1) Axial strain test of the test tube

[0036] Axial strain gauges are pasted on the outer wall of the test tube, and the axial strain deformation ε of the test tube is measured after the high-pressure airflow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com