Method of manufacturing a sound absorbing panel

A technology of sound-absorbing panels and compartments, which is applied in the field of manufacturing sound-absorbing panels, which can solve problems such as the performance degradation of sound attenuation devices and the difficulty of integrating sound attenuation devices, and achieve the effect of small acoustic performance and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Throughout the drawings, the same or similar reference numerals refer to the same or similar structures or groups of structures.

[0046] Furthermore, in this specification, the terms "upstream", "midstream" and "downstream" are used to refer to sections of the nacelle, the upstream section corresponding to the upstream leading edge of the nacelle, and the downstream section corresponding to at the rear edge of the nacelle.

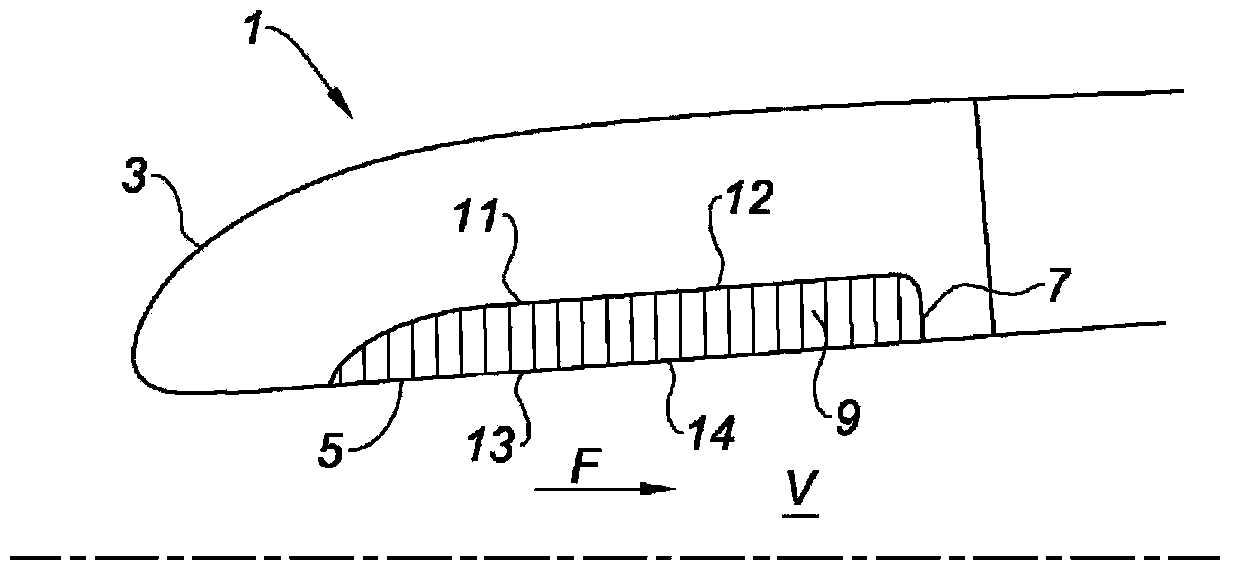

[0047] figure 1 A schematic diagram partially shows the upstream section of a nacelle 1 for a turbojet engine of an aircraft. This upstream section comprises the air intake lip 3 of the nacelle 1 , on the outside 5 of which is provided a sound-absorbing panel 7 for acoustically damping the noise and vibrations generated by the turbojet engine of said aircraft.

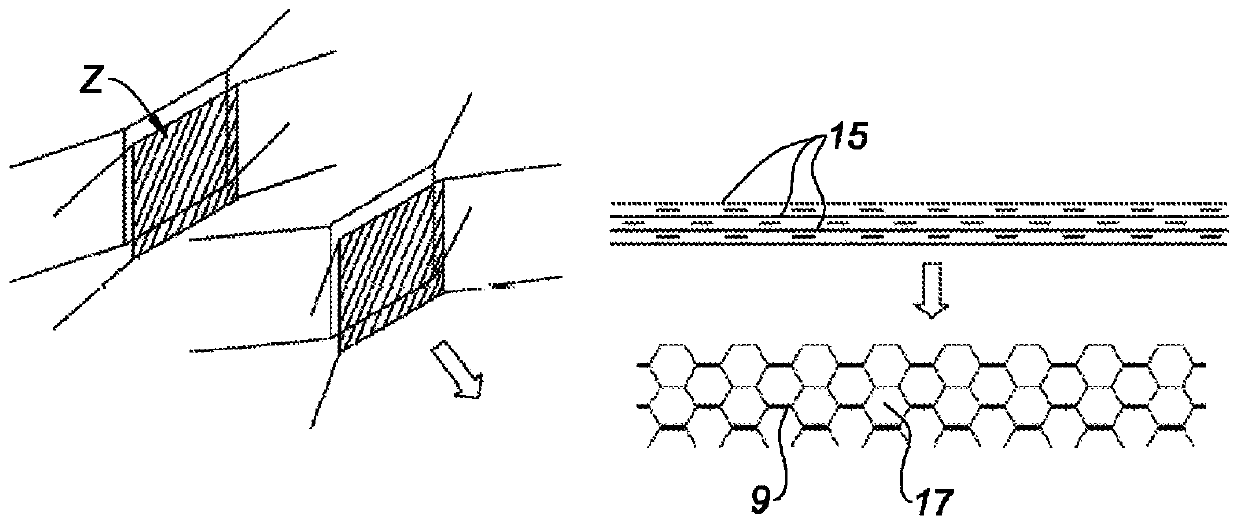

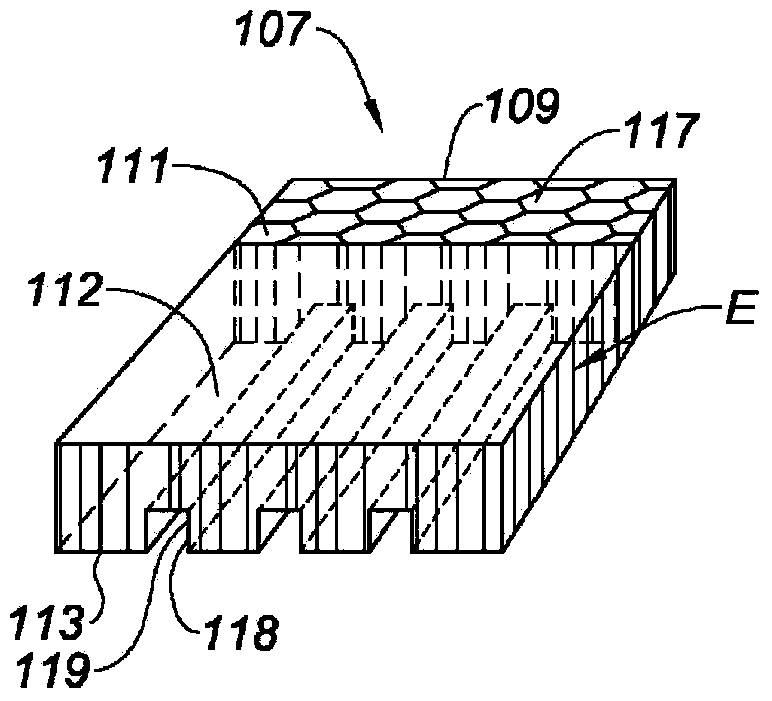

[0048] It is known that an acoustic panel comprises at least one set of acoustic cells to provide sound treatment, on its inner surface 11 is mounted an inner wall 12 and on its outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com