Cable tray plate positioning and square hole perforation device table mechanism

A technology of installation table and positioning punch, which is applied in positioning device, feeding device, peeling device, etc., can solve the problems of unreasonable design of installation table, affecting work efficiency, unstable positioning, etc., achieving reasonable design, improving work efficiency, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

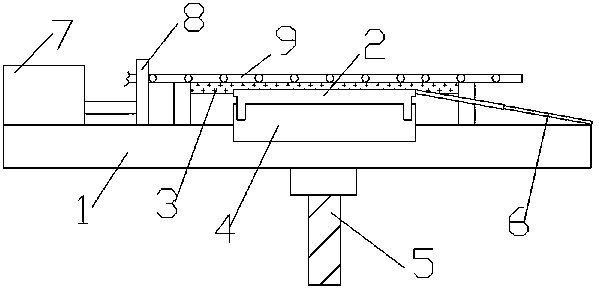

[0012] Such as figure 1 Shown: a device table mechanism for positioning and punching square holes of bridge plate in this embodiment, including a device table 1, a positioning mold 2, a positioning bar 3 and a mounting plate 4, wherein the mounting plate 4 is fixed on the recess of the device table 1 In the slot, an adjusting bolt 5 passes through the bottom of the device table 1 and is fixedly connected with the mounting plate 4 . The two ends of the bottom of the positioning mold 2 are respectively embedded and fixed on the mounting plate 4, the positioning strip 3 is positioned at the rear end of the positioning mold 2 and fixed on the device table 1; the top of the positioning strip 3 The ventilation pipe 9 is fixedly arranged, and several air outlets are arranged on the surface of the ventilation pipe 9; wherein the surface of the positioning bar 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com