Concave bulletproof ceramic plate

A technology of ceramic sheet and concave shape, which is applied in the field of bulletproof ceramic sheet structure, can solve the problems of poor bulletproof performance of splicing parts, etc., and achieve the effect of strong defense ability, reduced looseness, and good bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

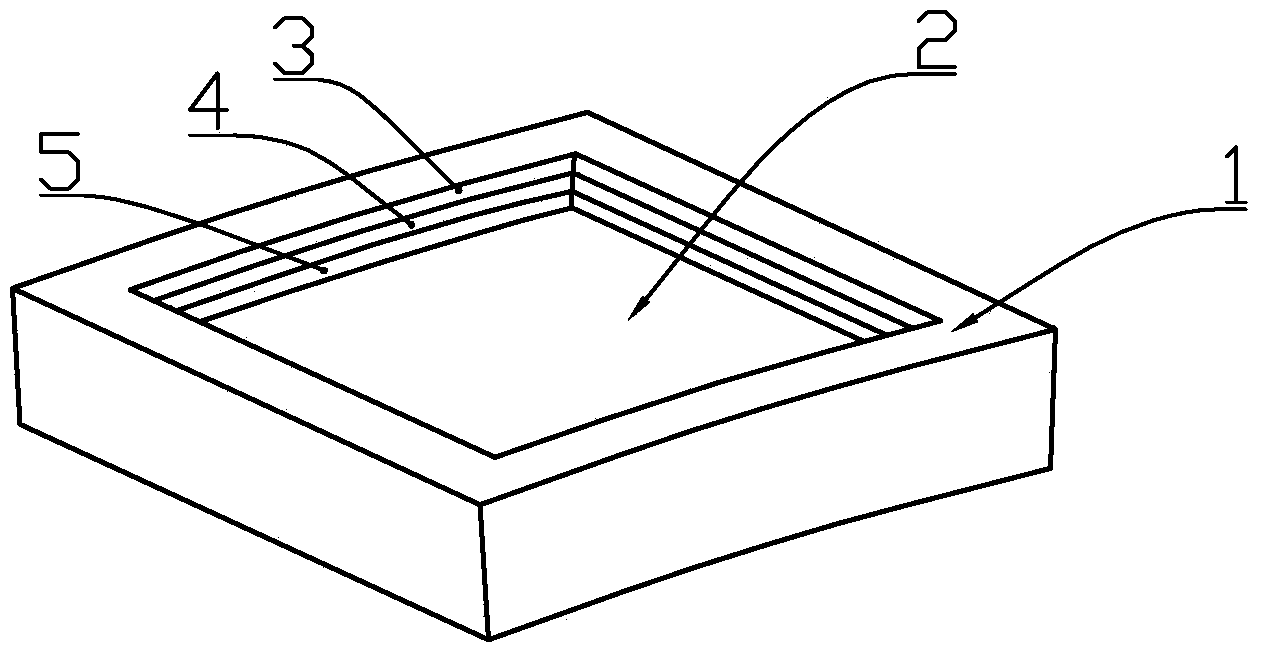

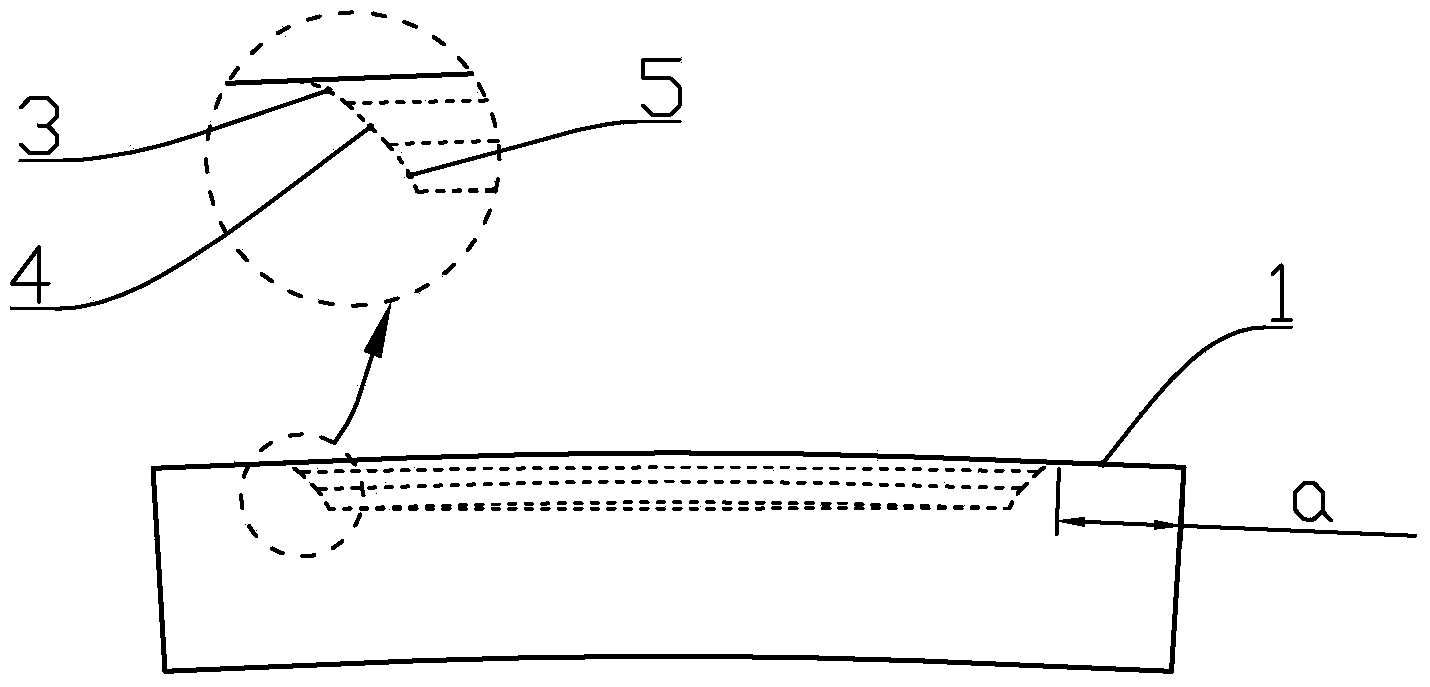

[0009] according to figure 1 and figure 2 As shown, a concave bulletproof ceramic sheet described in this embodiment, the ceramic sheet includes two arched surfaces parallel to each other, the line connecting the four vertices of the arched surfaces forms a square, and the center of the two arched surfaces faces The one protruding outward is the bullet-resisting surface 1, and a square notch 2 is provided above the bomb-resisting surface. The side walls of the notch from top to bottom are the first arc surface 3, the plane 4 and the second arc connected end to end. 5, and the angle between the extended surface of the plane and the bottom surface of the notch is 135 degrees; the distance from the upper edge of the side wall of the notch to the end of the arched surface is 1 / 9 of the length of the arched surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com