Injection Moulded Unupholstered Plastic Chair

A technology of injection molding and seats, applied to chairs, other seating furniture, stools, etc., can solve the problems of easily damaged cushions or upholstery, undesired cushions, increased seat costs and inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

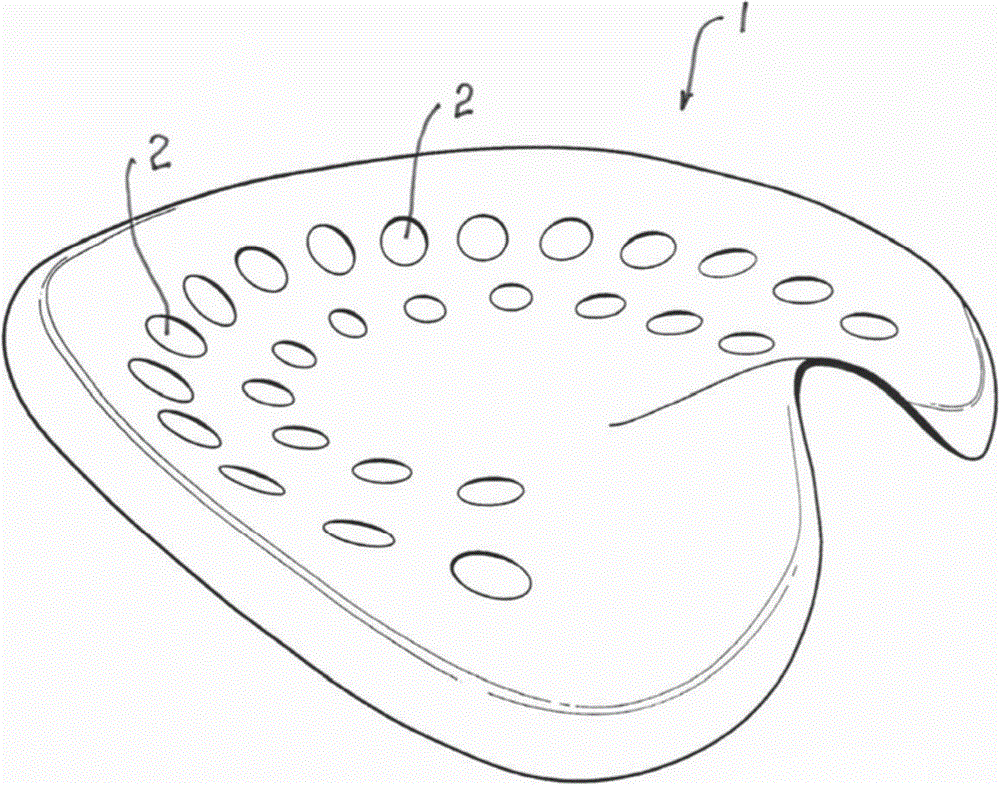

[0037] Referring now to the accompanying drawings, figure 1 An old tractor seat 1 stamped from metal is shown. Such tractors are required to be operated for a long period of time, the seat elasticity is poor and driver fatigue is a serious problem. Since the tractor has no cabin and does not have any roof or other shelter, the seat is provided with a relatively large number of openings 2 mainly to enable rainwater to drain from the seat. Such metal seats 1 were replaced by upholstered seats with the introduction of tractor cabins.

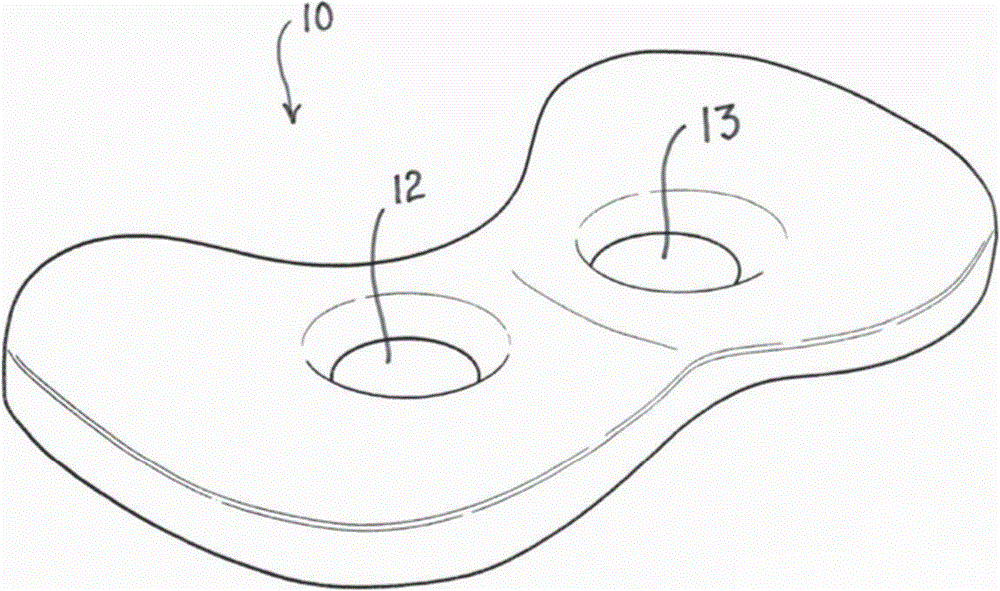

[0038] now refer to figure 2 , shows a conventional seat 10 for rowing boats used for more than 100 years with two through holes 12, 13 provided therein. The spacing between the through holes 12 and the through holes 13 approximately corresponds to the spacing between the ischial tuberosities of an adult male. The seat 10 is specifically designed to accommodate the back-and-forth rocking motion of the rower's spine during paddling, and the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com