Bypass type vector thrust device suitable for small unmanned aerial vehicle

A small unmanned aerial vehicle, vector thrust technology, applied in the direction of aircraft power plant, aircraft power plant components, aircraft parts, etc., can solve the problem of unmanned aerial vehicles without practical use, and achieve low cost, light weight, and technical implementation conditions mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

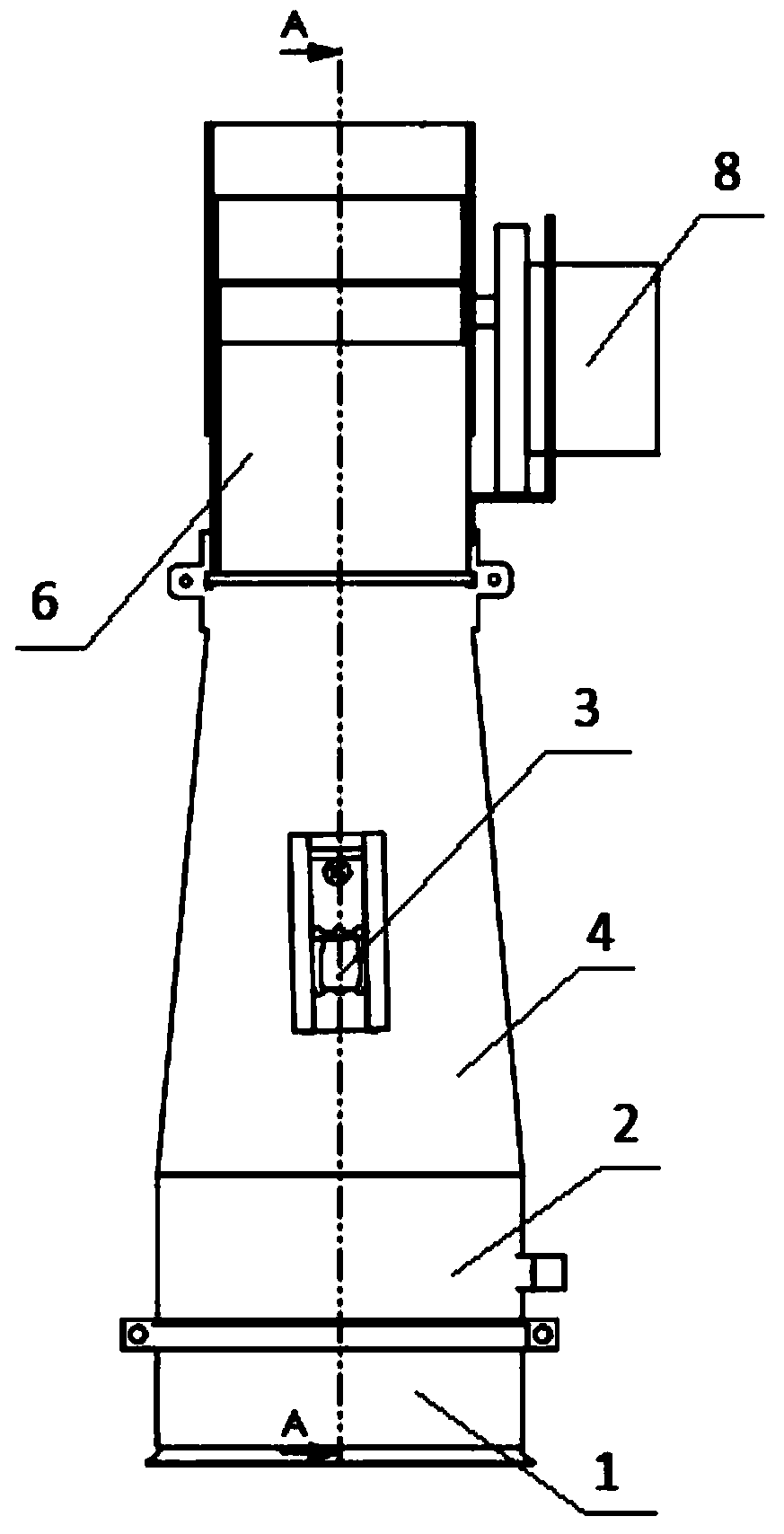

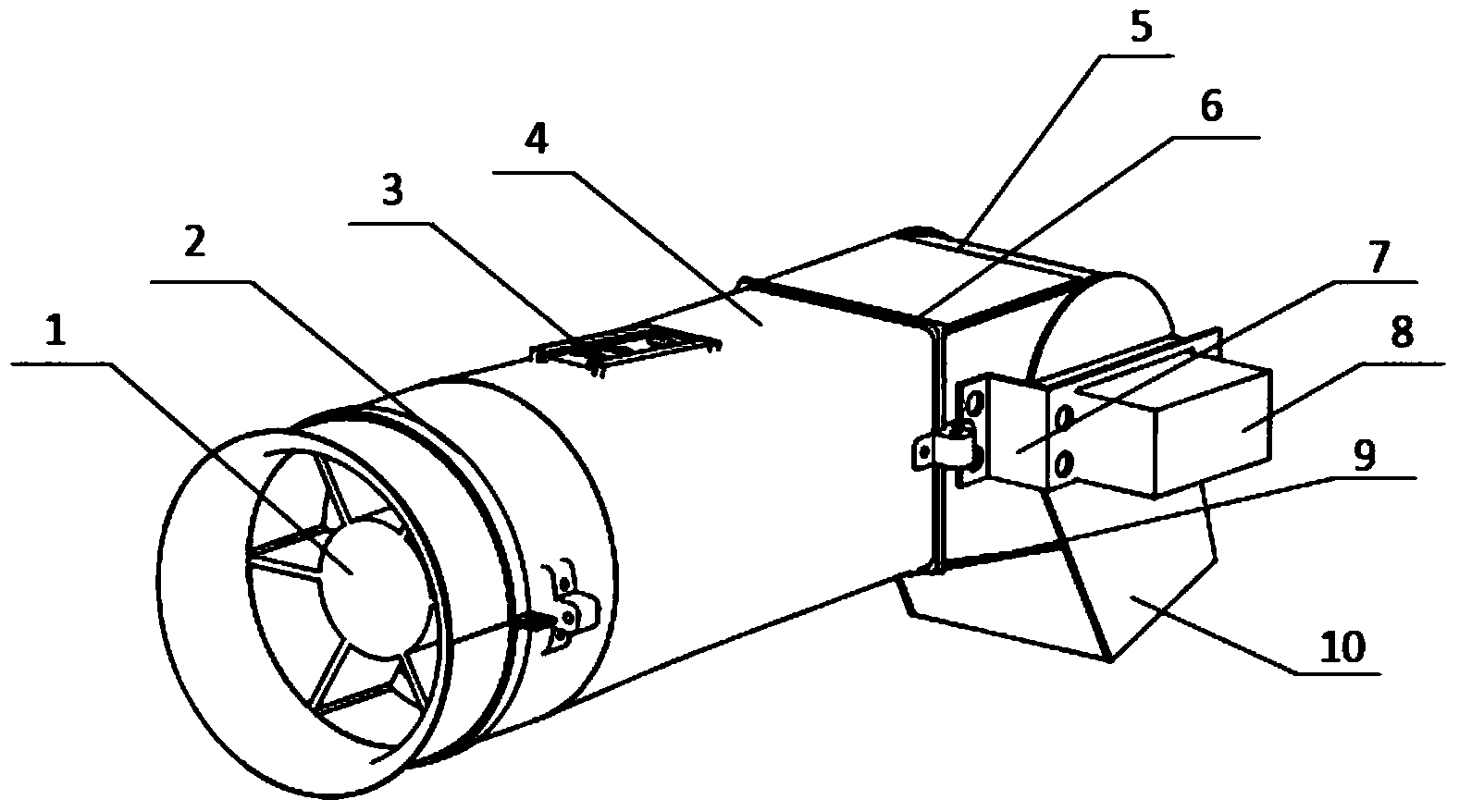

[0018] See attached figure 1 , 2 , 3, the ducted vector thrust device suitable for small unmanned aerial vehicles, it includes: the thrust generating device for generating the airflow, the vectoring nozzle assembly for changing the direction of the airflow and the connecting thrust generating device and the vectoring nozzle assembly diversion device;

[0019] The thrust generating device is a ducted fan 1;

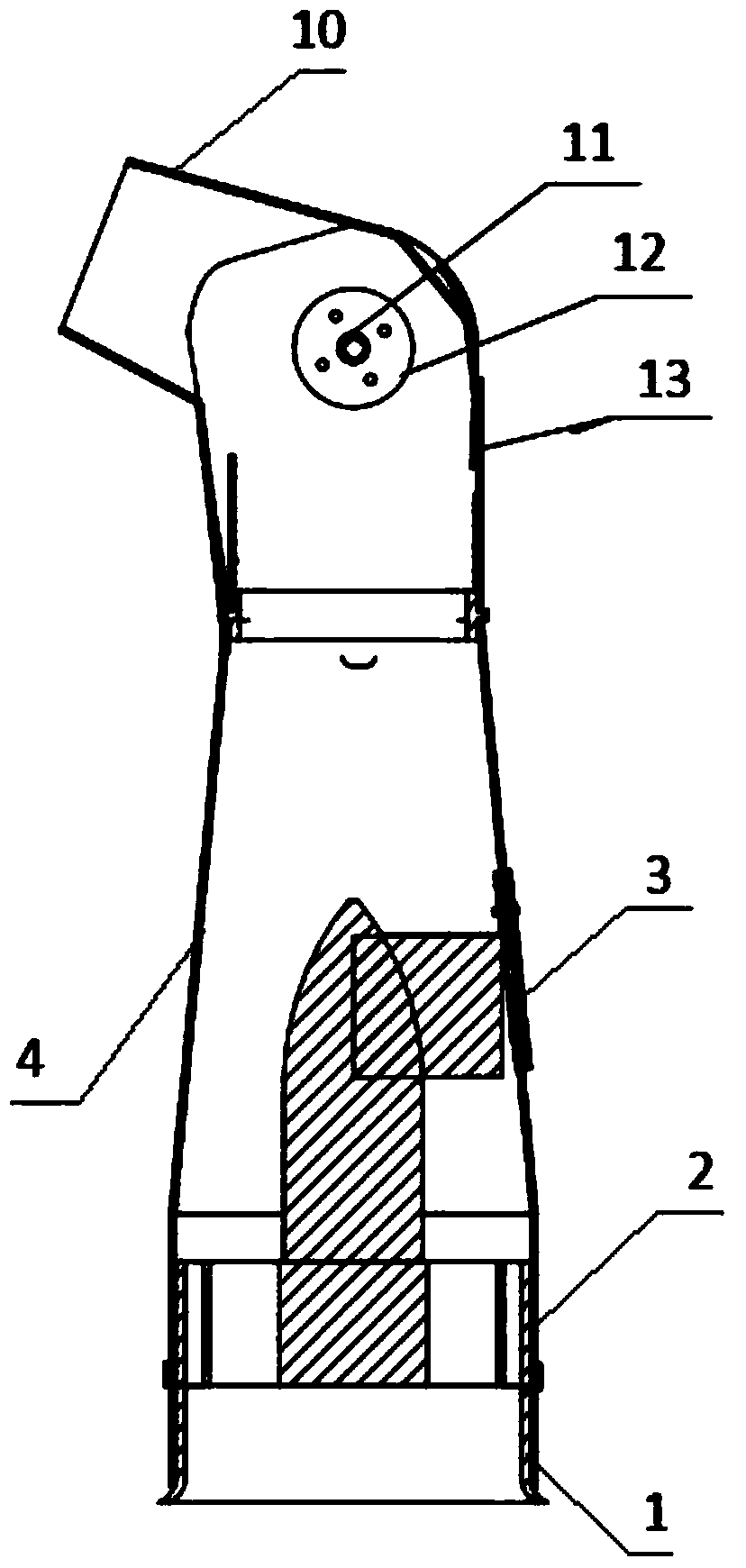

[0020] The diversion device includes: a pipeline 4 and a circular fixing ring 2 and a square fixing ring 6 installed at the front and rear ends of the pipeline 4; the front end port of the pipeline 4 is circular, the rear end port is square, and the middle part is contracted and smoothly transitioned; The middle part of 4 is provided with a lead window 3, which is used to lead out the power line and oil pipe of the ducted fan; the inner wall of the square fixing ring 6 is provided with an upper slideway 13 and a slideway 14;

[0021] See attached Figure 4 , 5 , the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com