Air bearing type manipulator gravity compensation device based on annular air bearing platform

An air-floating platform and air-bearing technology, which is applied to the simulation device of space navigation conditions, manipulators, transportation and packaging, etc., can solve the problems of no multi-joint space manipulator gravity compensation system, etc., and achieve easy understanding and implementation, structure Simple, highly simulated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

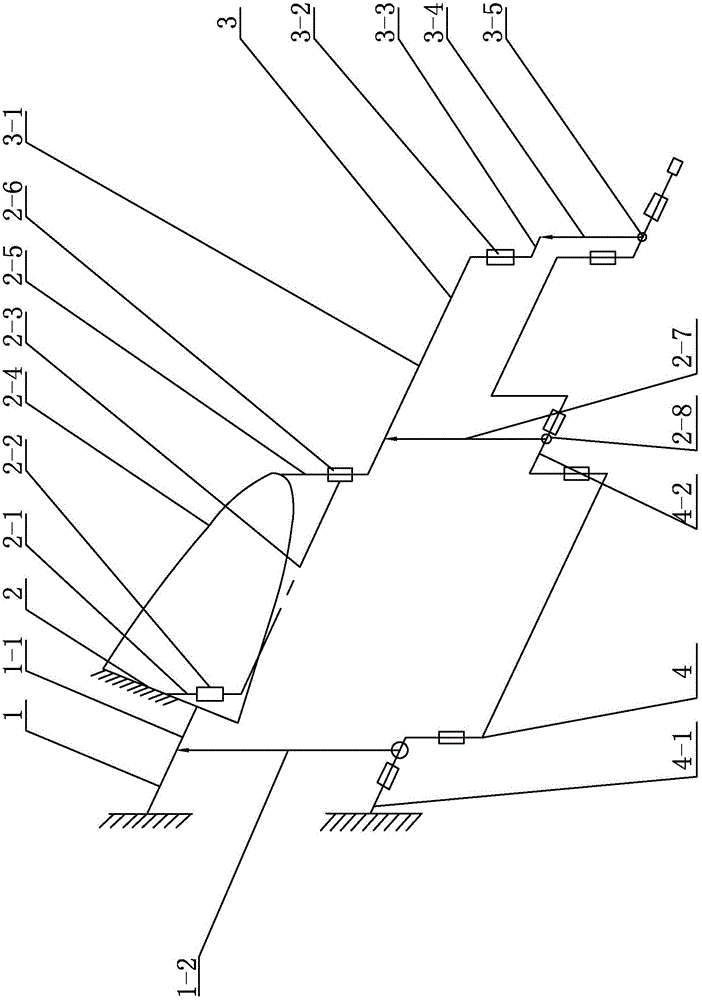

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the air bearing type manipulator gravity compensation device based on the annular air bearing platform in this embodiment includes a fixed suspension mechanism 1, a main rotary arm air bearing platform tracking suspension mechanism 2 and a secondary rotary arm tracking suspension mechanism 3 , the fixed suspension mechanism 1 and the main rotary arm air-floating platform tracking suspension mechanism 2 are installed on the steel frame, and one end of the auxiliary rotary arm tracking suspension mechanism 3 is connected with the main rotary arm air-floating platform tracking suspension mechanism 2.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment, the fixed suspension mechanism 1 of the air bearing type manipulator gravity compensation device based on the annular air bearing platform in this embodiment includes a first rod 1-1, a first suspension plate 1-2 and a first bearing , the upper end of the first suspension plate 1-2 is connected with the middle part of the first bar 1-1, and the lower end of the first suspension plate 1-2 is connected with the first mechanical arm bar 4-1 of the mechanical arm 4 through the first bearing. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, the main rotary arm air bearing platform tracking suspension mechanism 2 of the air bearing type manipulator gravity compensation device based on the annular air bearing platform in this embodiment includes a second rod 2-1, a first rotary joint 2 -2. Main slewing arm 2-3, air bearing platform 2-4, third rod 2-5, second rotating joint 2-6, second suspension plate 2-7 and second bearing 2-8, air bearing platform One end of 2-4 is connected with one end of the first rod 1-1, the other end of the air-floating platform 2-4 is connected with the upper end of the third rod 2-5, and the upper end of the second rod 2-1 is connected with the air-floating platform 2- 4 connection, the lower end of the second rod 2-1 is connected with one end of the main rotary arm 2-3 through the first rotary joint 2-2, and the other end of the main rotary arm 2-3 is connected with the third rotary arm 2-6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com