Electromagnetic speed adjusting three-phase asynchronous motor

A three-phase asynchronous, electromagnetic speed regulation technology, applied in the direction of AC motor control, electrical components, emergency protection circuit devices, etc. The effect of preventing electric leakage accident and electric shock accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

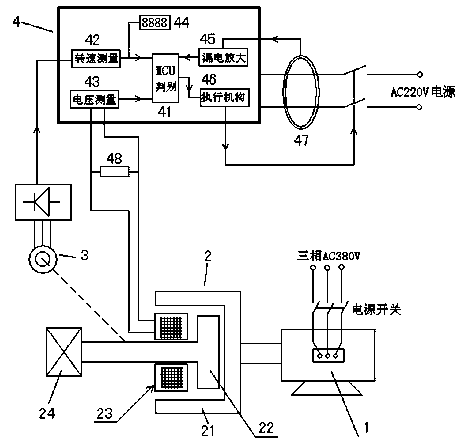

[0024] like figure 1 As shown, the electromagnetic speed-regulating three-phase asynchronous motor of the present invention includes a three-phase asynchronous motor 1, an electromagnetic slip clutch 2, and a speed controller 4. The three-phase asynchronous motor 1 is connected to an electromagnetic slip clutch 2, and the electromagnetic slip clutch 2 is set The speed controller 4; the stepless speed regulation of the motor is realized through the electromagnetic slip clutch 2;

[0025] Three-phase asynchronous motor 1 is powered by AC380V three-phase asynchronous motor power supply; speed controller 4 is powered by AC220V speed controller power supply;

[0026] The electromagnetic slip clutch 2 includes a cylindrical armature 21 and a claw-shaped magnetic pole 22. The three-phase asynchronous motor 1 is connected to the cylindrical armature 21, and the claw-shaped magnetic pole 22 is connected to the load 24 through the output shaft; the claw-shaped magnetic pole 22 is covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com