Paper packing plate and paper packing case

A technology for packaging boards and boxes, which is applied in packaging, transportation and packaging, and packaging of vulnerable items. It can solve the problems of increasing manufacturing costs and increasing material management costs, and achieve cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

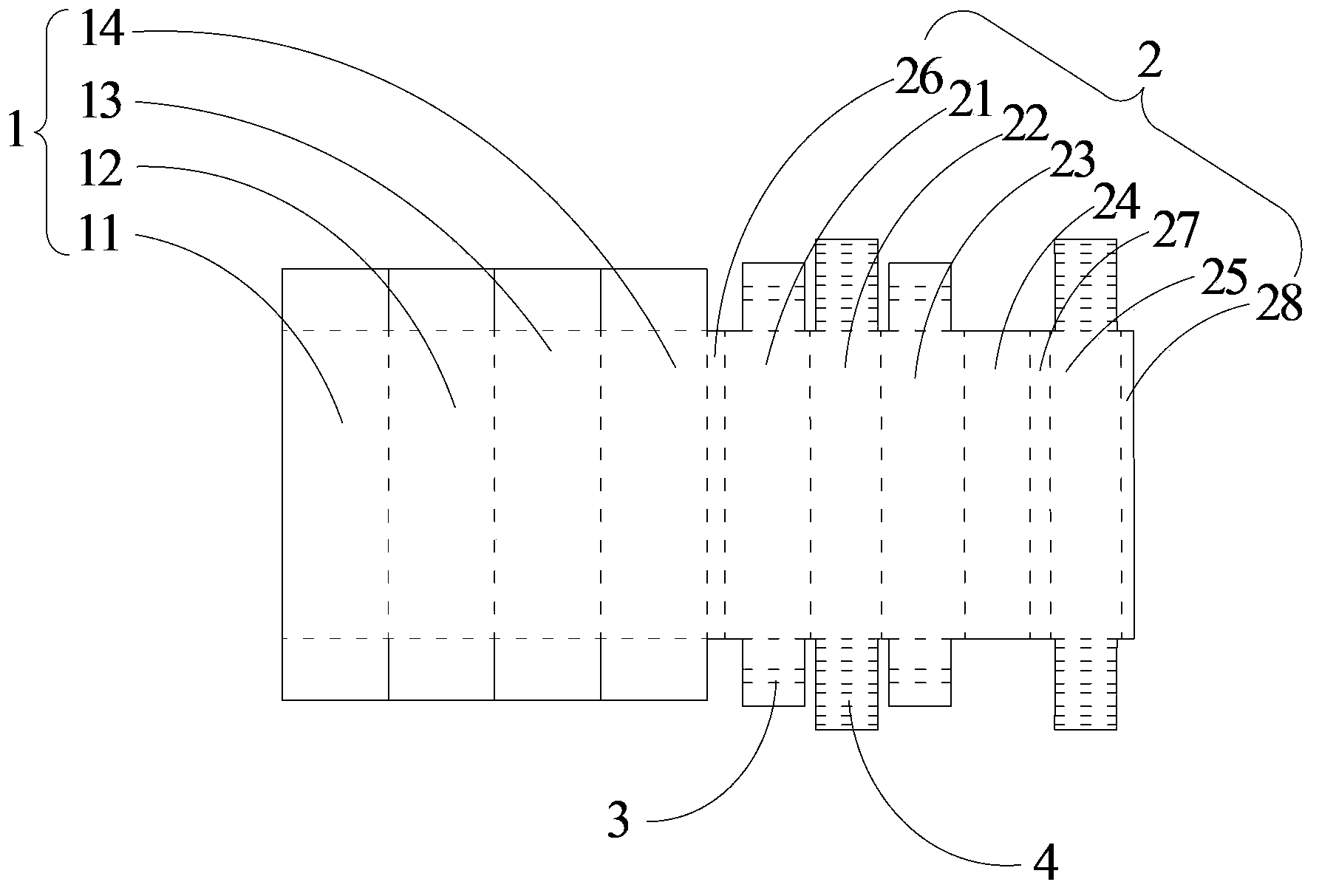

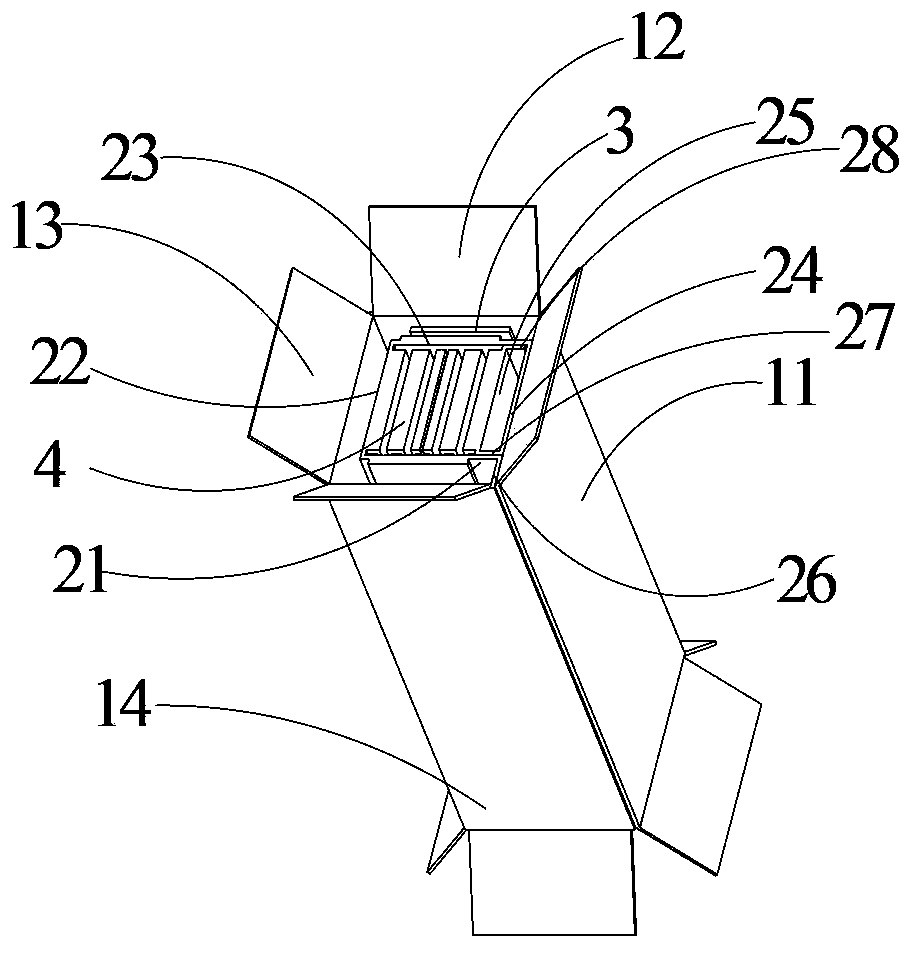

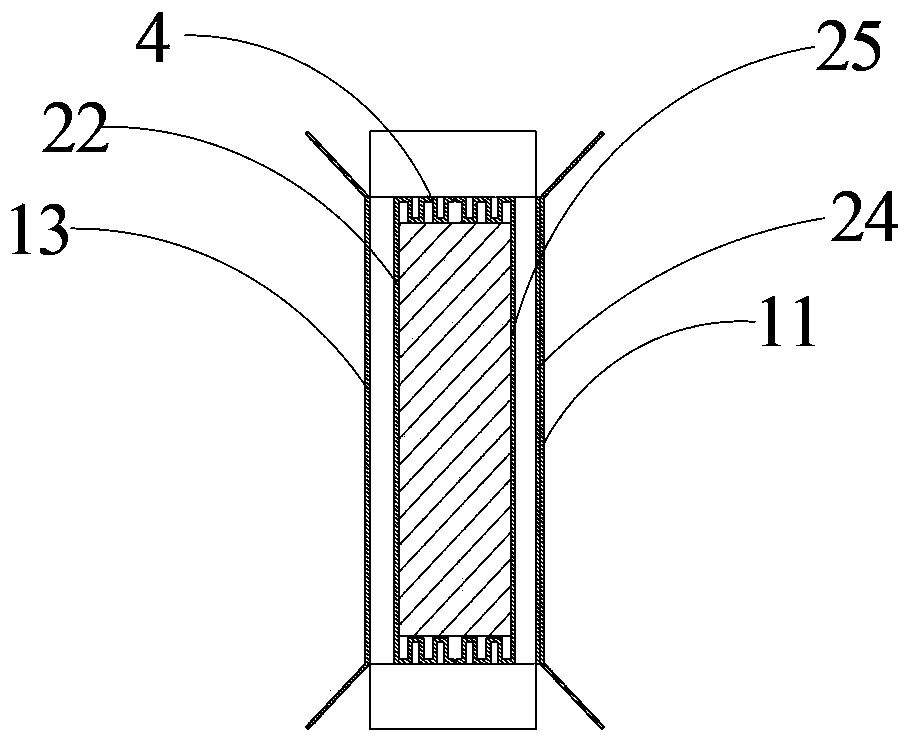

[0022] see Figure 1 to Figure 5 , The present invention provides a paper packaging board. The paper packaging board includes an outer box part 1, an inner box part 2, at least one supporting part 3 and at least one covering part 4, and the paper packaging board is integrally formed.

[0023] Outer box part 1, the outer box part 1 is rectangular, used for folding to form the outer box. In this embodiment, the outer box part includes four outer box side walls (11, 12, 13, 14), and the four outer box side walls (11, 12, 13, 14) are connected end to end in turn, and the outer box side walls ( 11, 12, 13, 14) are provided with creases at the joints. Selecting four outer box side walls (11, 12, 13, 14) is because the outer box is arranged as a cuboid. In other embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com