Double-side container dumper

A technology for loading and unloading trucks and containers, which is applied in the directions of loading/unloading, transportation and packaging, etc. It can solve the problems of small outrigger span, large vehicle length, and large installation space, so as to increase the outrigger span and shorten the whole vehicle The effect of small length and installation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

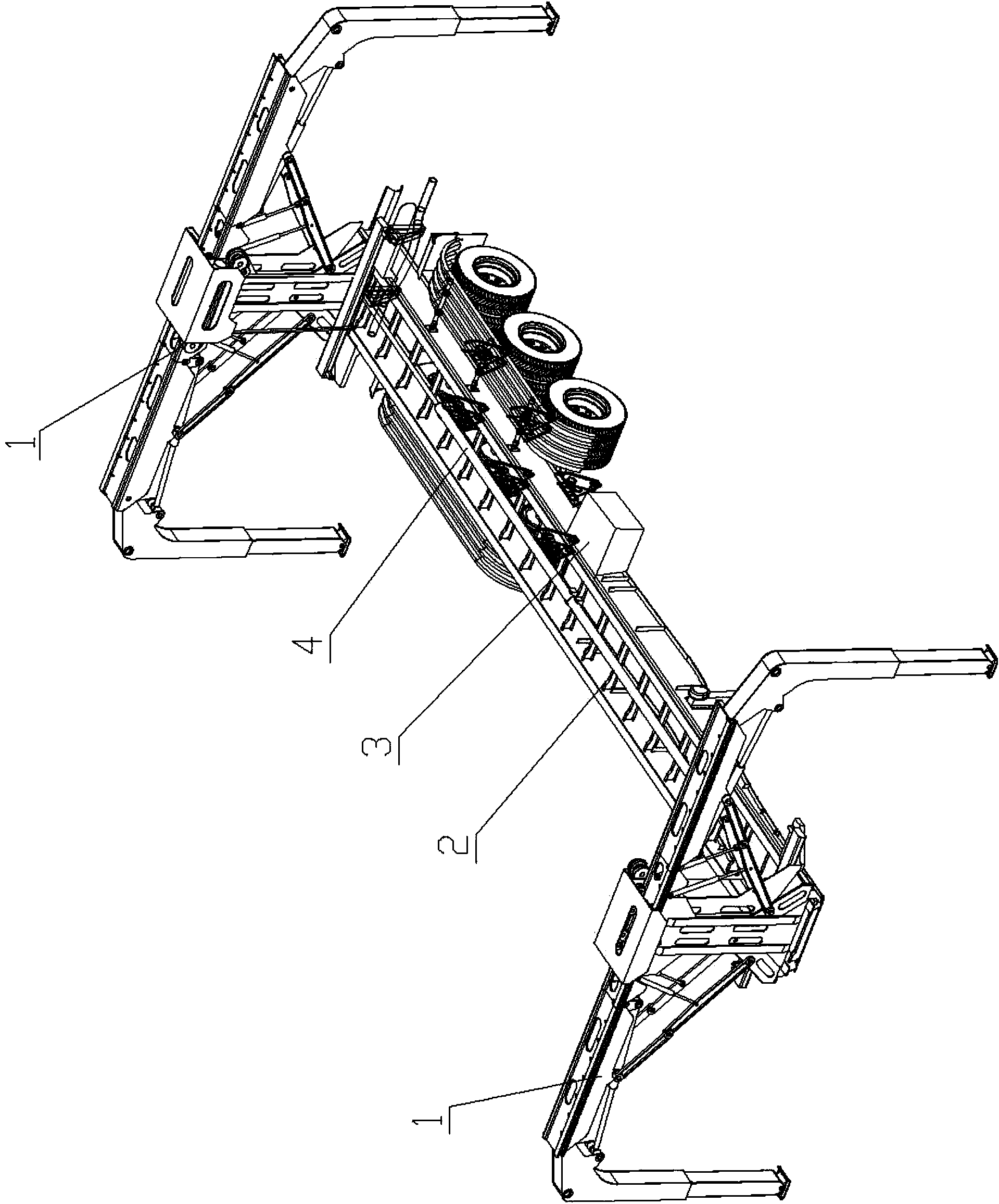

[0028] Please refer to the attached figure 1 to attach Figure 9 Shown, the present invention is a kind of container double-side self-loading truck, and it is made up of several parts such as trailer 2, crane 1 and mobile oil cylinder 4.

[0029] Wherein, the cranes 1 are respectively installed at the front and rear ends of the trailer 2, and the structures of the front and rear cranes 1 are the same. The two ends of the mobile cylinder 4 are respectively hinged on the lower part of the front and rear cranes 1, and the middle is hinged on the trailer 2. The expansion and contraction of the mobile cylinder 4 drives the crane 1 to move back and forth on the trailer 2 to meet the requirements of the 20" or 40" container. loading and unloading. A power system 3 can also be installed on the side of the trailer 2, if the tractor can output power, the power system 3 does not need to be installed.

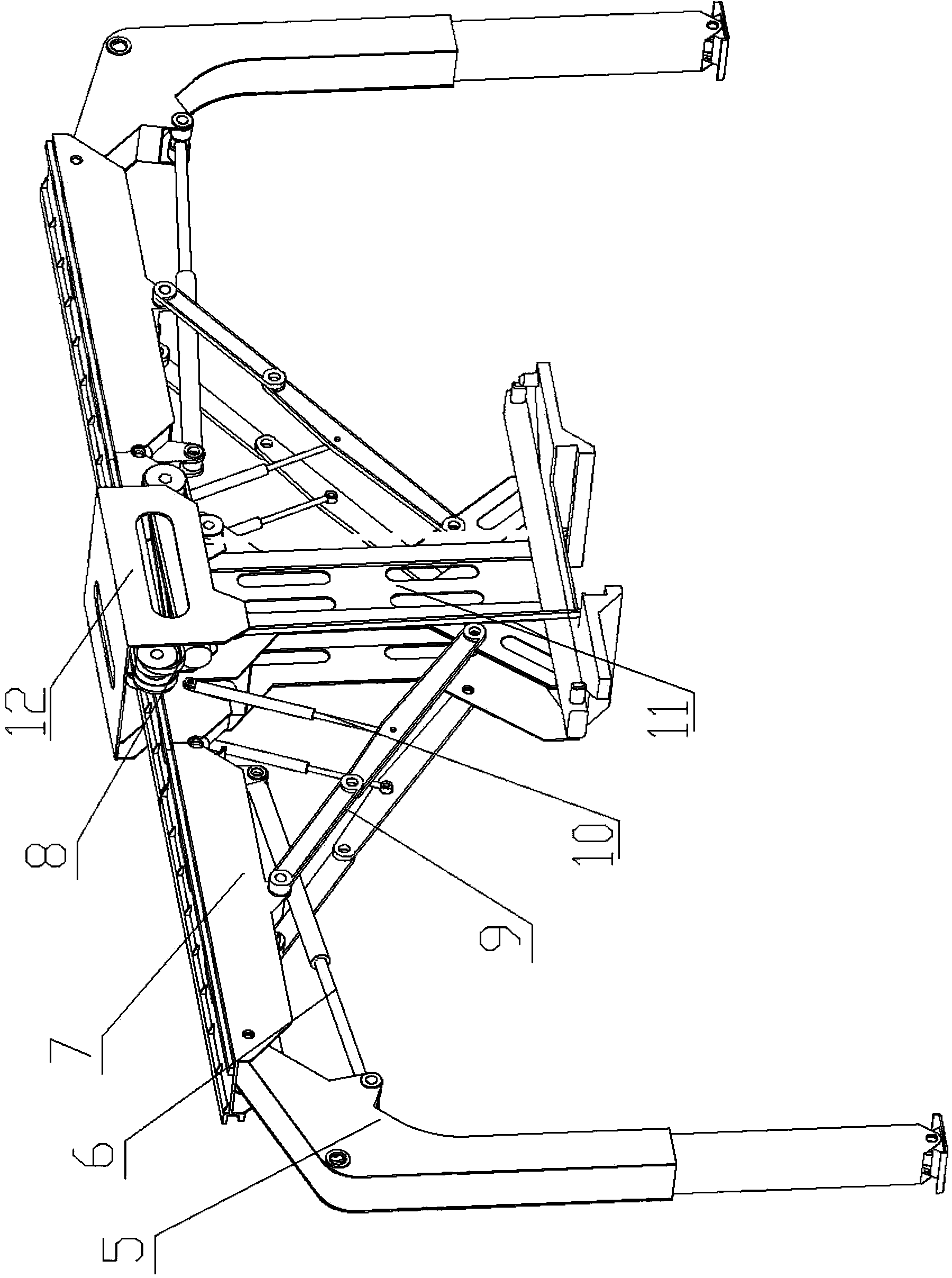

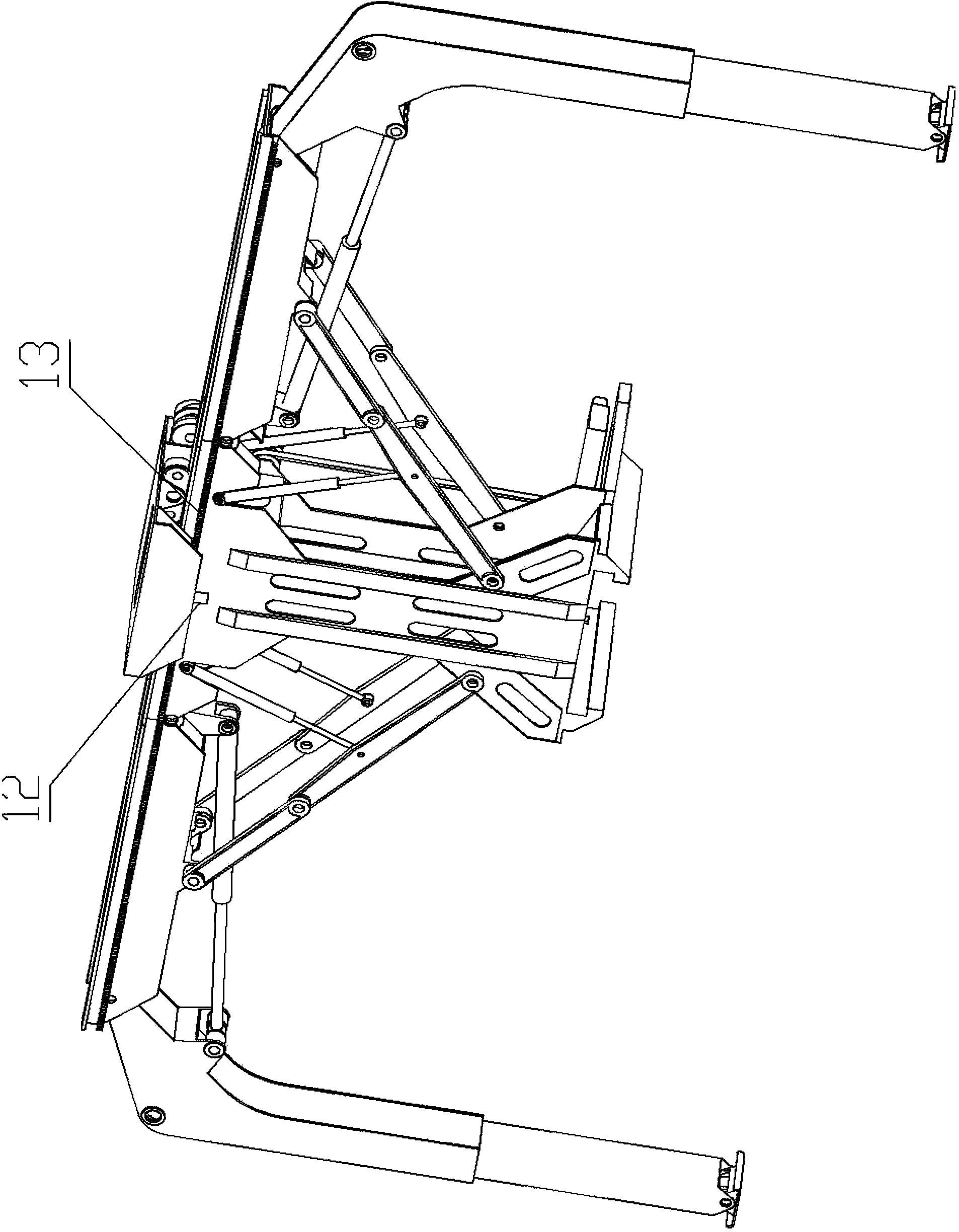

[0030] Further, the crane 1 is composed of an intermediate frame 11, a lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com