Parallel four-linkage carrying device

A technology of parallel four-bar linkage and handling device, which is applied in the direction of lifting device, transportation and packaging, lifting frame, etc., which can solve the problems of low energy utilization rate, large torque variation range, unfavorable energy saving and emission reduction, etc., and achieve the improvement of loading and unloading civilization level, avoiding interference, and saving logistics energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is an embodiment of the "parallel four-bar linkage conveying device" of the present invention, which is only a preferred solution and does not limit the content of the present invention, and is now further described in conjunction with the accompanying drawings.

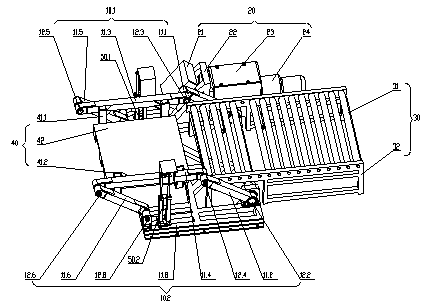

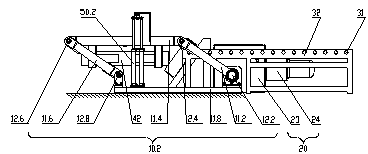

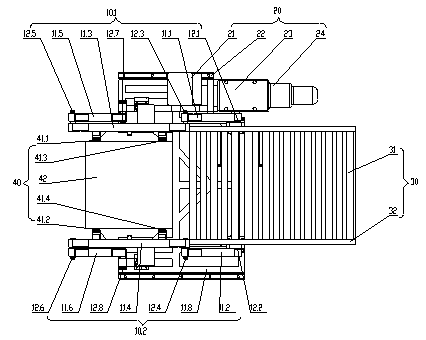

[0027] Such as Figure 1 to Figure 3 As shown, it is an embodiment of a parallelogram handling device of the present invention, which consists of two sets of parallelogram hinge mechanisms (10.1 and 10.2), two sets of driving force supply devices (50.1 and 50.2), a set of electric power systems (20), a group of cargo transmission mechanism (30) and a cargo platform (40) are composed of five units, and its characteristic is that each group of parallelogram hinge mechanism (10.1, 10.2) is connected with a short shaft and its bearing ( 12.3 and 12.4, 12.5 and 12.6, 12.7 and 12.8) use known methods to connect the four connecting rods (11.1 and 11.2, 11.3 and 11.4, 11.5 and 11.6, 11.7 and 11.8) end to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com