A resistive hydrogen sensor based on nanocomposite material and its preparation method

A nanocomposite material and composite material technology are applied in the field of resistive hydrogen gas sensor based on nanocomposite material and its preparation, which can solve problems such as non-quantification, and achieve the effects of simple operation, stable product performance and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take a 4cm×0.8cm titanium piece, ultrasonically clean it in ethanol and acetone for 1 hour respectively, dry it under nitrogen flow, and set it aside.

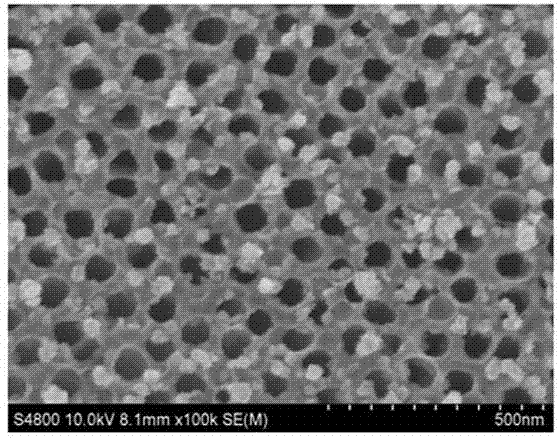

[0027] 2) Take 0.6686 g NH 4 Dissolve F in 5 ml of water, add 195 ml of ethylene glycol to it, stir, and use two electrodes to electrodeposit titanium oxide sheets to form TiO on the surface of the titanium sheets. 2 Nanotubes, using Pt as the negative electrode and titanium sheet as the positive electrode, with an oxidation potential of 60 V, were taken out after 1 h, washed with absolute ethanol, ultrasonicated in absolute ethanol for 3 s, dried in air, and placed in a muffle furnace at 450 °C Firing 3h.

[0028] 3) The fired titanium sheet was used as the working electrode, Pt was used as the counter electrode, and 0.1 mM PdCl at pH=3 2 , deposited at a constant potential of -0.3 V for 3 min, removed, washed with deionized water, and dried in air.

[0029] 4) Use the above titanium sheet as the working electrod...

Embodiment 2

[0032] Take a 4 cm × 0.8 cm titanium piece, ultrasonically clean it in ethanol and acetone for 1 hour each, and dry it under nitrogen flow for later use.

[0033] 2) Take 0.6686 g NH 4 Dissolve F in 5 ml of water, add 195 ml of ethylene glycol to it, stir, and use two electrodes to electrodeposit titanium oxide sheets to form TiO on the surface of the titanium sheets. 2 Nanotubes, using Pt as the negative electrode and titanium sheet as the positive electrode, with an oxidation potential of 60 V, were taken out after 1 h, washed with absolute ethanol, ultrasonicated in absolute ethanol for 3 s, dried in air, and placed in a muffle furnace at 450 °C Firing 3h.

[0034] 3) The fired titanium sheet was used as the working electrode, Pt was used as the counter electrode, and the 0.1 mM H 3 PtCl 6 , deposited at a constant potential of -0.5V for 3 min, removed, washed with deionized water, and dried in air.

[0035] 4) Use the above-mentioned titanium sheet as the working elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com