Piezoelectric type hydrogen sensor and its preparation and uses

A sensor and piezoelectric technology, applied in the field of hydrogen sensors, can solve the problems of transportation and storage leakage, non-quantitative detection, small hydrogen molecular weight, etc., and achieve the effects of simple operation, low manufacturing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take 50mg of multi-walled carbon nanotubes (MWNTs), in 3M HNO 3 Reflux for 3 hours, then wash, filter, and dry at 60°C for later use.

[0026] 2) Take 5mg of MWNTs, in turn in 0.1M SnCl 2 +0.1M HCl, 1mM PdCl 2 Immerse in +0.1M HCl for 10min, 4 consecutive times, filter, wash and dry.

[0027] Disperse it in 1 mM PdCl with 2 mL of ammonia added dropwise 2 +0.1M HCl+60g / L EDTA100ml solution, add 50μL N 2 h 4 , heated to 50°C, after 50min, filtered, washed and dried. Pd nanoparticles can be well combined with carbon nanotubes, such as Figure 1 Show.

[0028] 3) Put the quartz crystal sheet Cr / Pt (9M Hz) in concentrated H 2 SO 4 : 30%H 2 o 2 Soak in the solution of (1:3) for 20 minutes, take out and soak in absolute ethanol for 20 minutes, and then dry under infrared lamp.

[0029] 4) Disperse 2mg of Pd-MWNTs composite material into 2mL of DMF solution, and sonicate for 30 minutes.

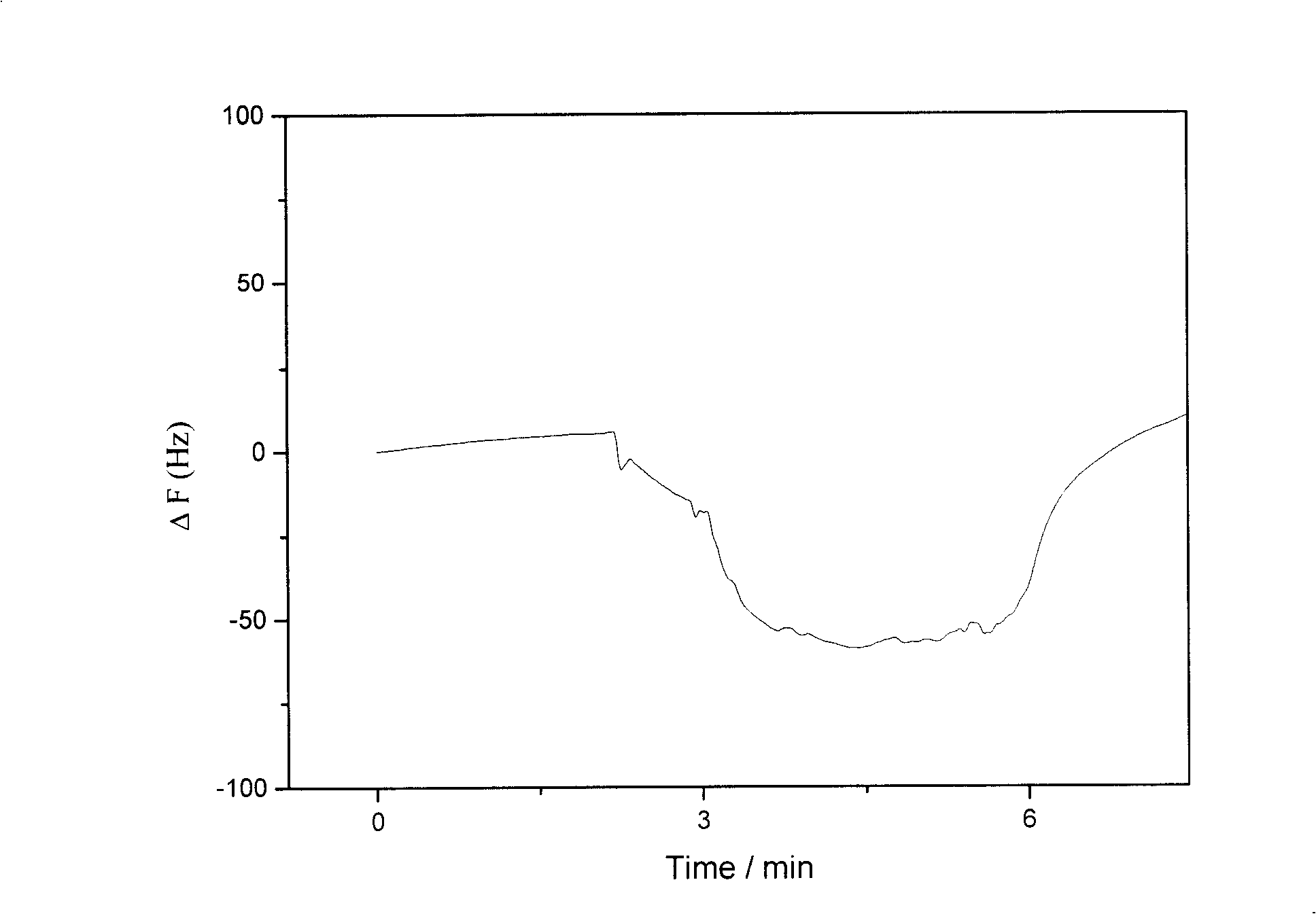

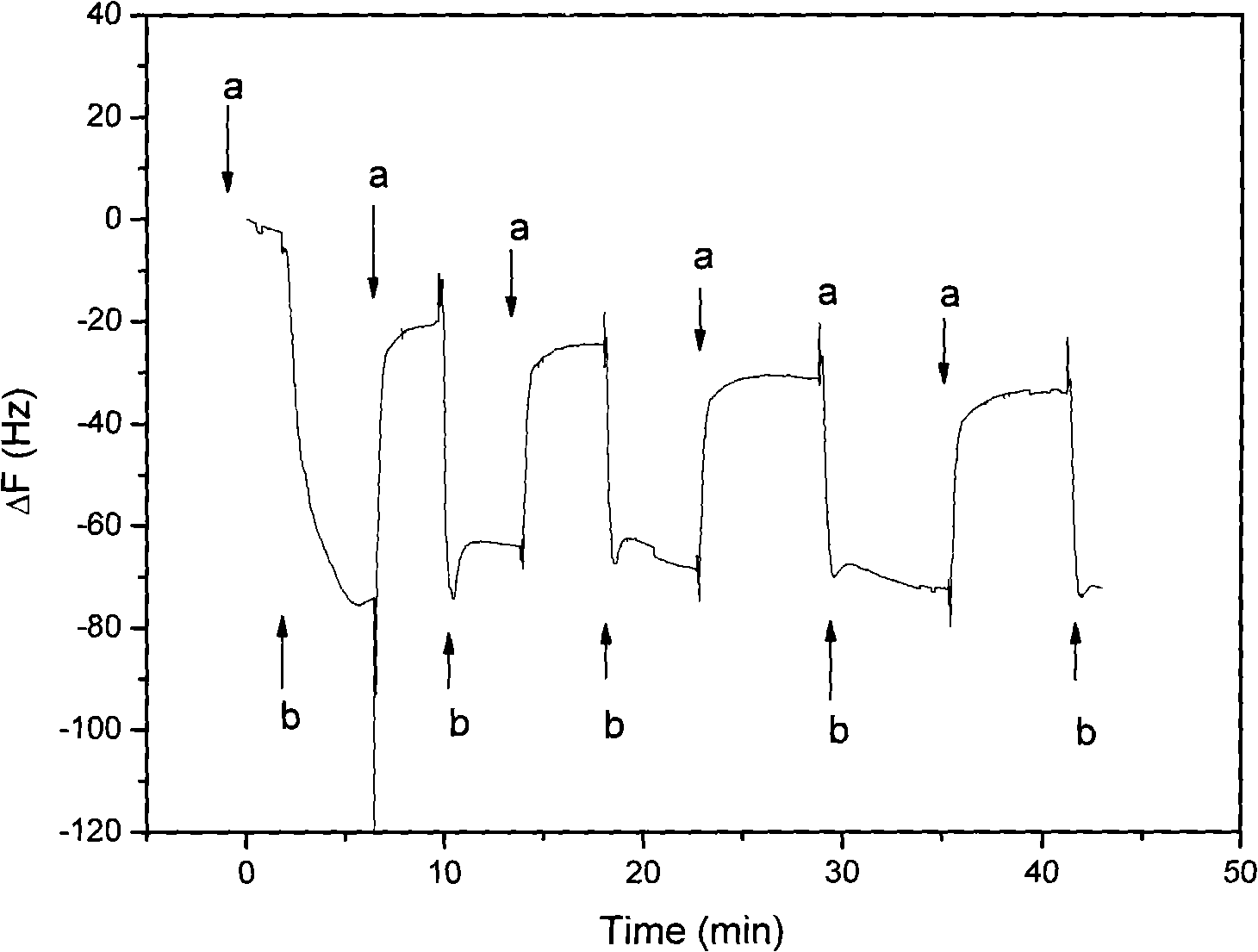

[0030] 5) Take 10 μL of the above dispersion liquid and drop it on the ele...

Embodiment 2

[0032] 1) Remove 100mg of SiO 2 (100 mesh), followed by 0.1M SnCl 2 +0.1M HCl, 1mM PdCl 2 Immerse in +0.1M HCl for 10min, 4 consecutive times, filter, wash and dry.

[0033] Disperse it in 1 mM PdCl with 2 mL of ammonia added dropwise 2 +0.1M HCl+60g / L EDTA100ml solution, add 50μL N 2 h 4 , heated to 50°C, after 50min, filtered, washed and dried to obtain Pd-SiO 2 nanocomposites.

[0034] 2) Quartz crystal plate Cr / Pt (9M Hz) in concentrated H 2 SO 4 : 30%H 2 o 2 Soak in the solution of (1:3) for 20 minutes, take out and soak in absolute ethanol for 20 minutes, and then dry under infrared lamp.

[0035] 3) Take 2mg of Pd-SiO 2 The composite material was dispersed into 2mL DMF solution and sonicated for 30 minutes.

[0036] 4) Take 10 μL of the above-mentioned dispersion liquid, drop it on the electrode surface of the quartz crystal plate, test it on the quartz crystal microbalance after the solvent evaporates, and record the relationship between the frequency chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com