Tobacco product heating device

A technology for heating devices and smoking products, which is applied to electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of inconvenience to consumers and the changing laws of components released by smoking products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 (the ventilation part of the first heating matrix is a ventilation hole type)

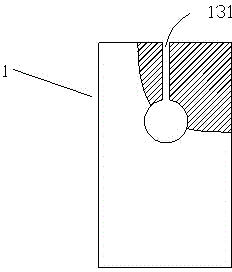

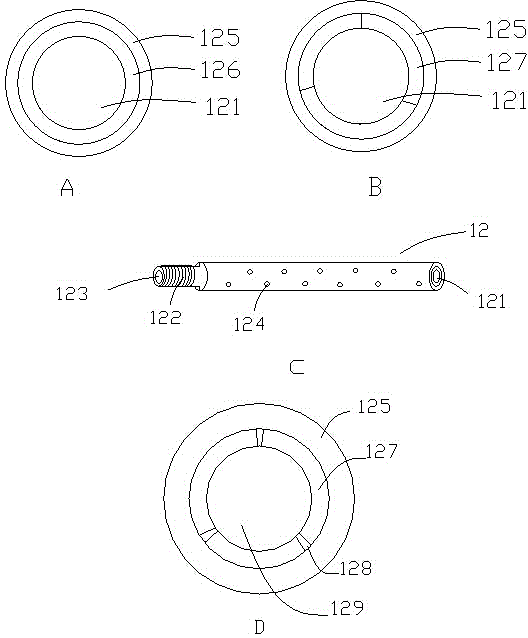

[0084] The structure of the heating device of the present invention is as Figure 1~Figure 12 shown. It includes a first heating body 1, a second heating body 6, and a controller 2 for controlling the heating of each heating body. The first heating body 1 includes a first heating matrix 13 and a first sleeve 12. The first set The tube 12 is provided with a first accommodation chamber 121, the first sleeve 12 is provided with at least one row of openings 124 arranged in the axial direction, and the first heat generating matrix 13 is provided with a ventilation part 131, and the openings and ventilation The relative positions of the parts are adjustable, so that the opening 124 can communicate with the ventilation part 131, and one end of the first sleeve 12 is provided with an air inlet 123, and the other end is provided with an air outlet;

[0085] The second heating body 6 ...

Embodiment 2

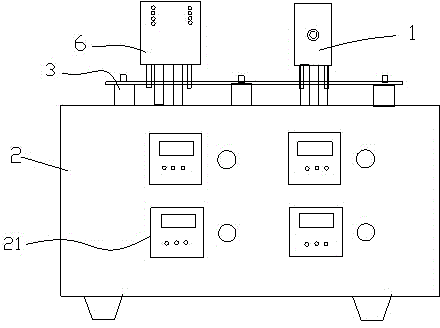

[0118] The structure of the heating device of the present invention is as Figure 8 shown. It includes a heating element 1 and an electric box loaded with a controller 2 for controlling heating of the heating element 1 . The top of the electric box is provided with a fixed bracket 3, and the heating element 1 is fixed on the fixed bracket 3. The electric box is provided with a display screen 21 and operation buttons, which can monitor and control changes in parameters such as temperature and time in the heating process.

[0119] The structure of the heating element 1 is the same as that of the first embodiment.

Embodiment 3

[0120] Embodiment 3 (the ventilation part is a ventilation groove type)

[0121] The structures of the heating device and the heating matrix described in this embodiment are as follows: Figure 13~Figure 14 shown. It includes a first heating body 1 and a controller 2 for controlling the heating of the heating body. The first heating body 1 includes a first heating matrix 13 and a first sleeve 12. The first heating matrix 13 is provided with a ventilation groove 131. The first The structure of the casing 12 refers to that of the first embodiment. The relative position of the opening 124 on the first sleeve 12 and the ventilation slot 131 is adjustable, so that the opening 124 can communicate with the ventilation slot 131 . The width ratio of the ventilation groove is slightly larger than the diameter of the hole 124 on the casing 12, and the width of the ventilation groove 131 is 1.1-1.5 mm.

[0122] The structure of the remaining parts of this embodiment is the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com