Stable and smooth molding machine structure with low failure rate

A low failure rate, molding machine technology, applied in the field of molding machine structure, can solve the problems of uncompact structure of molding capping machine, dirty molding machine, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

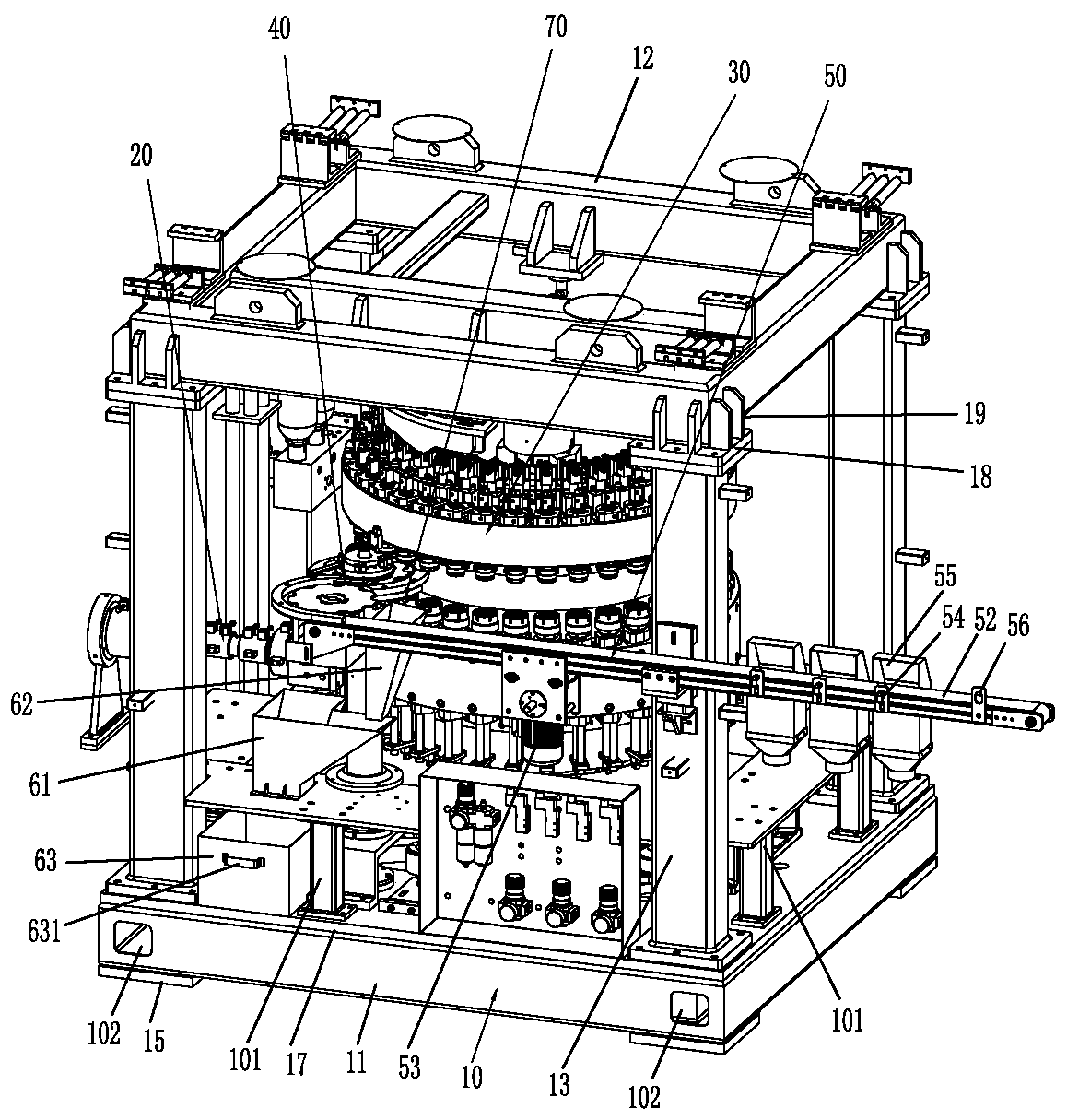

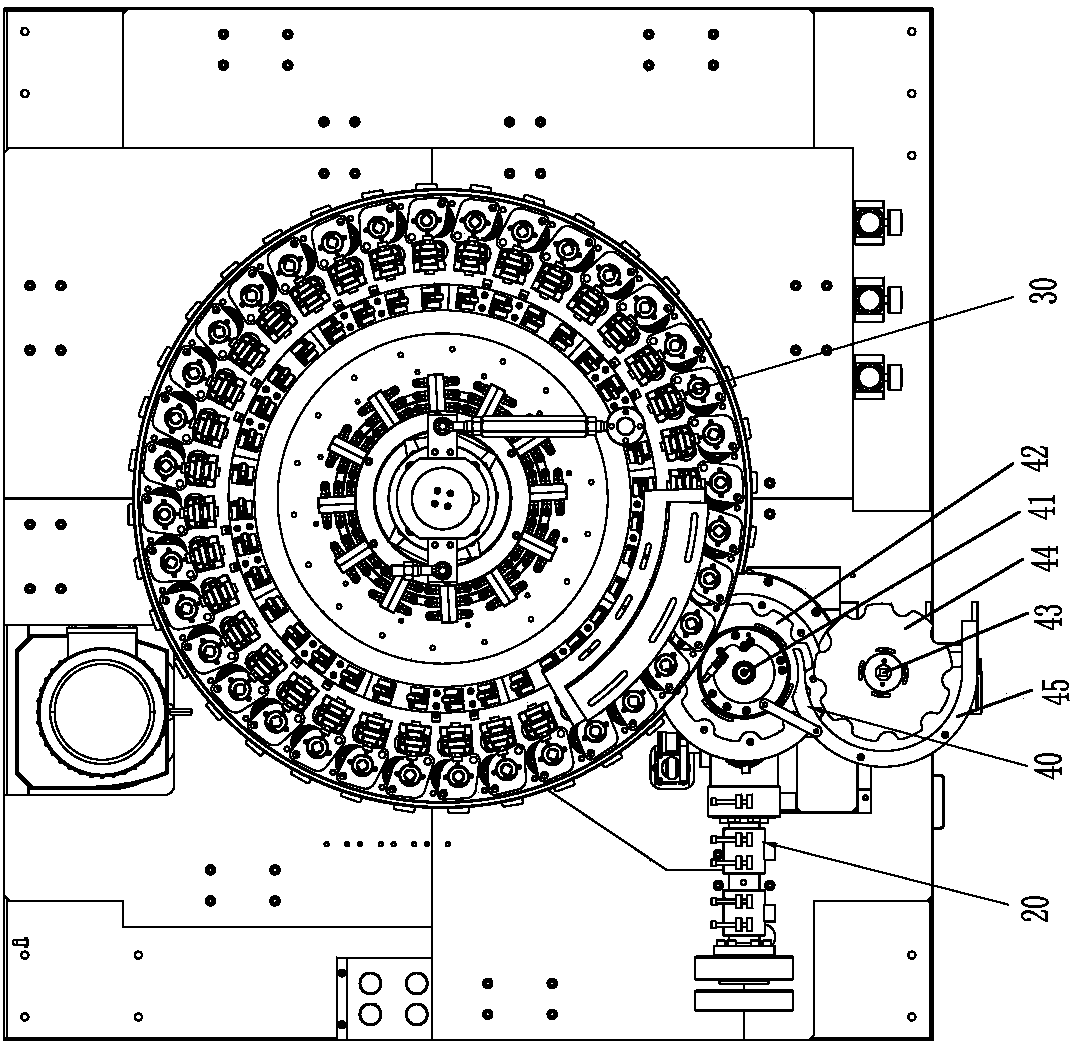

[0087] Please refer to Figure 1 to Figure 17 As shown, it has shown the concrete structure of the embodiment of the present invention, comprises frame 10, is arranged on the pressing mold group 30 on the frame 10, joins in the feeding and discharging mechanism 40 of one side of pressing module group 30 and is used for A bottle cap output track assembly 50 for automatically outputting formed bottle caps.

[0088] The pressing module 30 includes a molding disc rotating shaft, an upper molding pressing disc, and a lower molding pressing disc; The connecting plate is integrated with the upper mold plate and the lower mold plate and rotates synchronously with the rotary shaft of the mold plate; on the periphery of the upper mold plate, there are a plurality of upper molds that are equidistant and evenly distributed from the rotary axis of the mold plate; A bottom mold matched with the upper mold is arranged on the lower mold pressure plate, and the bottom mold is located directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com