High-pressure oxygen cabin door

A technology of hyperbaric oxygen chambers and hatches, which is applied in medical science, hospital equipment, treatment rooms, etc., can solve the problems of inconvenient stretcher vehicles, etc., and achieve the effect of smooth entry and exit, simple operation, and safe entry and exit of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

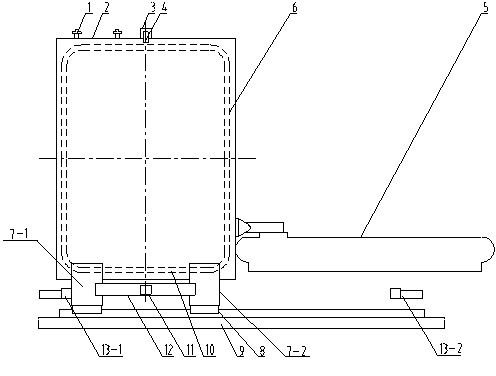

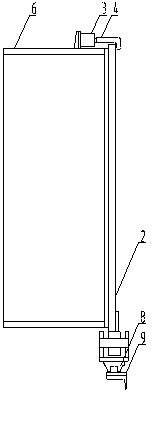

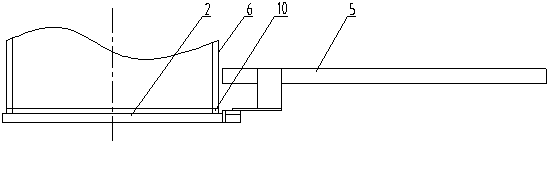

[0013] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further illustrate the structure of the present invention.

[0014] A kind of hyperbaric oxygen cabin hatch, refer to Figure 1-3 , including the hatch body 2, there is a hatch door sealing rubber 10 maintaining good airtightness on the periphery of the hatch body 2, a door frame 6 is arranged inside the hatch body 2, and a pulling locking device is installed above the hatch body 2 4 and the pulling and locking cylinder 3 that provides power for the pulling and locking device 4, the main movement cylinder 5 that pulls the hatch body 2 to open and close is installed on one side of the hatch body 2, and the bottom of the hatch body 2 is equipped with a push and move device, the main moving device 8 is installed under the pushing moving device, and the main moving device 8 is installed on the base 9, and the pushing moving device has two left pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com