Bidirectional-sensing compensating tank bearing and tank locking device for hoisting container

A sensing device and tank locking technology, which is applied in the field of cage receiving and compensating for locking the cage, can solve the problems of inability to detect the size of the tank supporting force and locking force of the equipment, the limited error height of the cage stopping the tank, and cumbersome operations, etc. Achieve the effect of shortening the lifting cycle time, improving the lifting efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

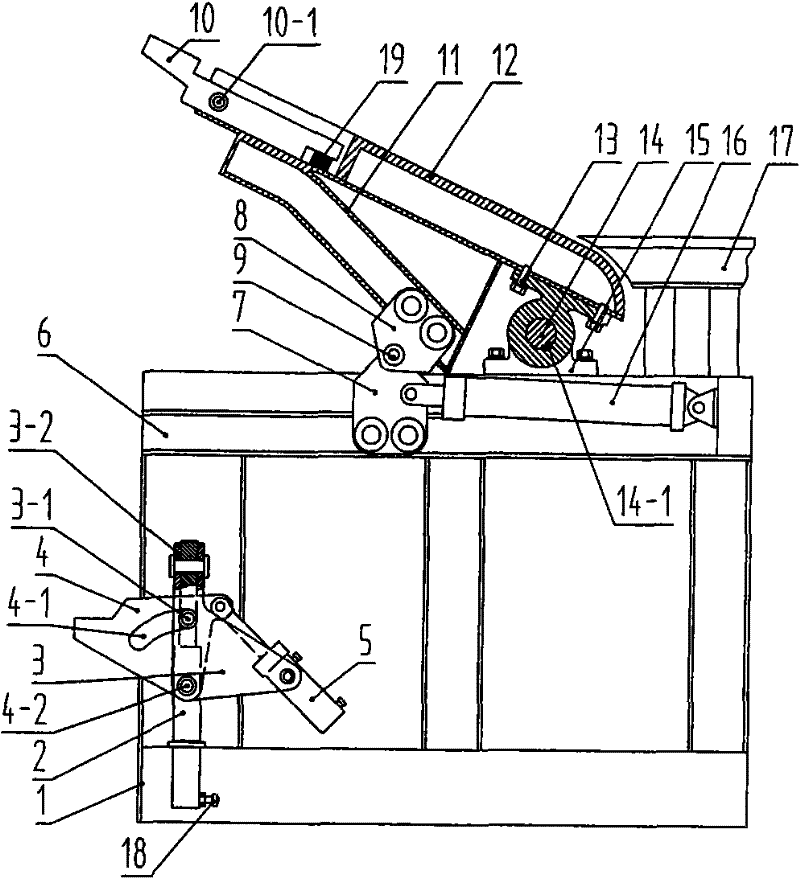

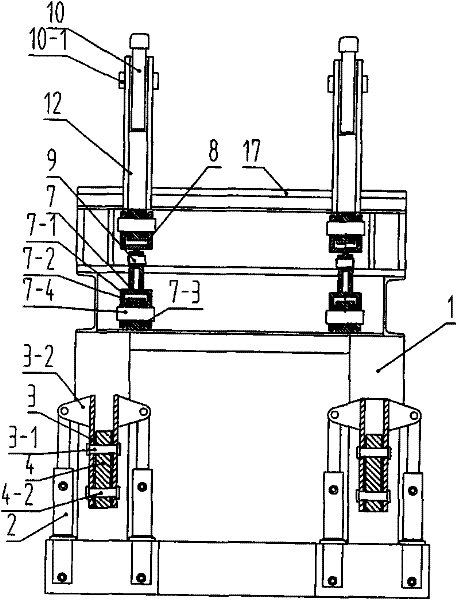

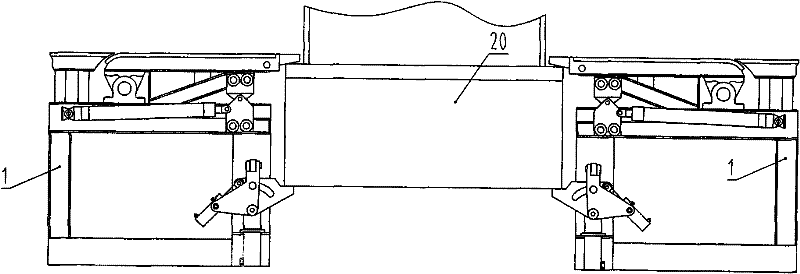

[0035] like figure 1 , figure 2 As shown: a two-way sensory compensation tank lock device for lifting containers includes: a frame 1, a tank support device installed inside the frame 1, and a tank lock device installed on the upper part of the frame 1; it is characterized in that: The load sensing device 18 is set on the device, and the tank locking device 19 is set on the tank locking device; the frame 1 is a steel rectangular frame;

[0036] The tank supporting device includes: a lifting cylinder 2, a lifting bracket 3, a supporting claw 4 and a conversion cylinder 5; the lifting bracket 3 is an asymmetrical triangular plate, and the upper part of the triangular plate vertically fixes the ear plate 3-2; The piston rod of the lift cylinder 2 is connected to the ear plate 3-2, and the cylinder body of the lift cylinder 2 is installed on the frame 1; the claw 4 is similar to a prismatic plate, and the claw 4 is clamped on the Between the two lifting brackets 3, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com