Pulling plate structure of explosion-proof dry-type transformer iron core

A dry-type transformer, pulling plate technology, applied in the direction of transformer/inductor magnetic core, inductance/transformer/magnet manufacturing, electrical components, etc. Concise, guaranteed fastening, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

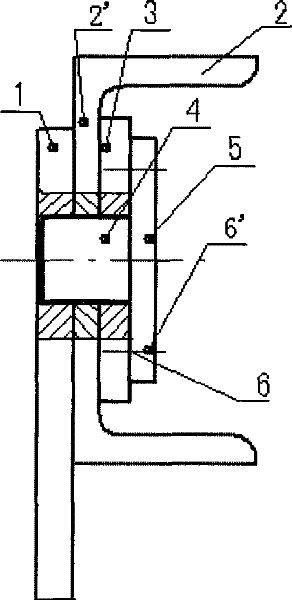

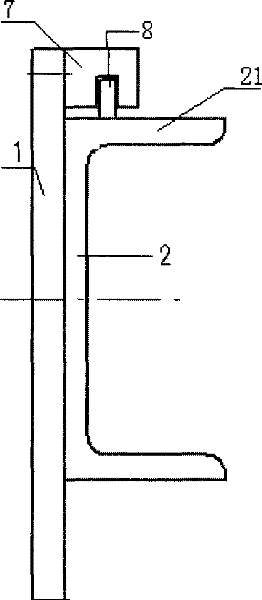

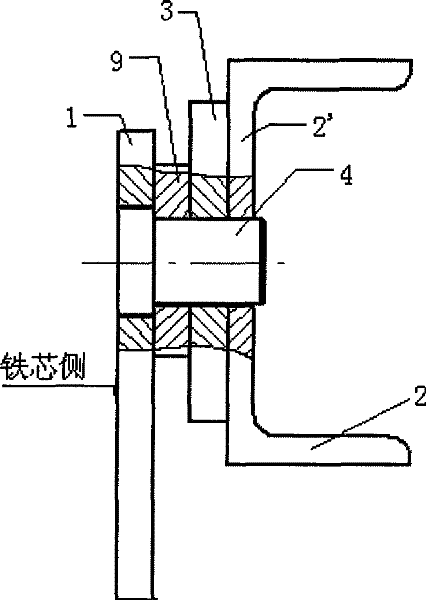

[0018] Such as image 3 , Is a schematic diagram of the pull plate structure of the present invention, including pull plate 1, clip 2 and pin 4, pull plate 1 and clip web 2'of clip 2 are connected by pin 4, pull plate 1 and clip web The opposite sides of the plate 2'are respectively welded with reinforcing plates, one end of the pin shaft 4 is stepped, the pull plate 1, the pull plate reinforcing plate 9, the clamping member reinforcing plate 3 and the clamping member web 2'are provided with pins at corresponding positions The corresponding hole of the shaft 4 forms a stepped pin hole from the pull plate 1 to the clamp 2. The larger end of the stepped pin hole is located on the pull plate 1, the pull plate 1, the pull plate reinforcing plate 9, and the clamp reinforcing plate 3. It is leaned against the web 2'of the clamping member in pairs, and is rigidly connected by the pin 4.

[0019] The extension plate 9 welded on the extension plate 1, considering the need to leave a weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com