A horizontal well reverse circulation jet screw drill

A technology of screw drilling and reverse circulation, which is applied in the research field of downhole operations in oilfield development, can solve the problems that the sand washing operation cannot be continued, affects the sand washing progress, and cannot be completely carried out of the ground, etc., and achieves compact structure, high torque Large, not easy to stick the effect of the drill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

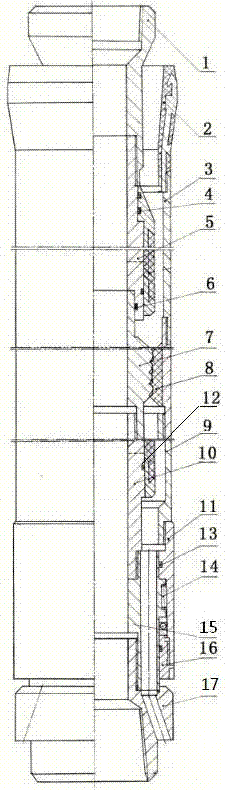

[0025] In order to overcome the problems that cables are easy to wear, drill tools are easy to get stuck, high safety risks, complex tripping procedures, low efficiency, and high labor intensity during the downhole process, this embodiment provides a method such as figure 1 As shown in the horizontal well reverse circulation jet screw drill, the outside of the screw drill includes the upper part of the upper joint 1, the upper cardan shaft housing 3, the stator 8, the lower cardan shaft housing 9, and the transmission shaft housing 11 connected in sequence from top to bottom And the sealing head 16, the inside of the screw drill includes the lower part of the upper joint 1, the upper cardan shaft 5, the rotor 7, the lower cardan shaft 10, the transmission shaft 15 and the spray head 17 connected sequentially from top to bottom, the middle of the upper joint 1 The sealing cup 2 is connected, the injection head 17 is provided with injection holes in the circumferential direction,...

Embodiment 2

[0030] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the shown horizontal well reverse circulation jet screw drill, the outer sides of the upper cardan shaft 5 and the lower cardan shaft 10 are connected with a sealing rubber tube. Since there are holes on the upper cardan shaft 5 and the lower cardan shaft 10, when the liquid flows through, a short flow phenomenon will occur, and the short flow of the liquid can be effectively prevented by the sealing effect of the sealing rubber tube.

[0031] Further, the rotor 7 is a hollow hollow rotor. The liquid entering from the casing passes through the sealing cup 2 to make the liquid flow together and then enters the working chamber of the motor. The motor is composed of the rotor 7 and the stator 8, which converts the liquid energy into the mechanical energy of the hollow rotor 7 to drive the spray head to rotate and make full use of it. energy, reducing costs.

Embodiment 3

[0033] On the basis of embodiment 2, this embodiment provides a kind of figure 1 In the shown horizontal well reverse circulation jet screw drill, the upper end and the lower end of the transmission shaft 15 are connected with bearings. The bearing has effectively prevented the transmission shaft 15 from jumping up and down during the rotation process.

[0034] Further, in order to prevent radial deflection of the transmission shaft 15 during rotation, a circle of needle rollers 14 is connected to the outer circumference of the transmission shaft (15), and both ends of the needle rollers 14 are round heads.

[0035] Furthermore, the injection holes of the injection head 17 are radially inclined from the inside to the outside. The spray head 17 rotates at a high speed, the spray holes are radially inclined from the inside to the outside, and the liquid is sprayed out in a divergent manner through the spray holes to form a high-pressure spray rotating fluid, requiring less circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com