Lock-up mechanism for slippage door and slippage door

A technology of locking mechanism and sliding door, which is applied in the field of sliding door, can solve problems such as influence of service life of guide wheel, drop, positioning failure, etc., and achieve the effect of simple and compact structure, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

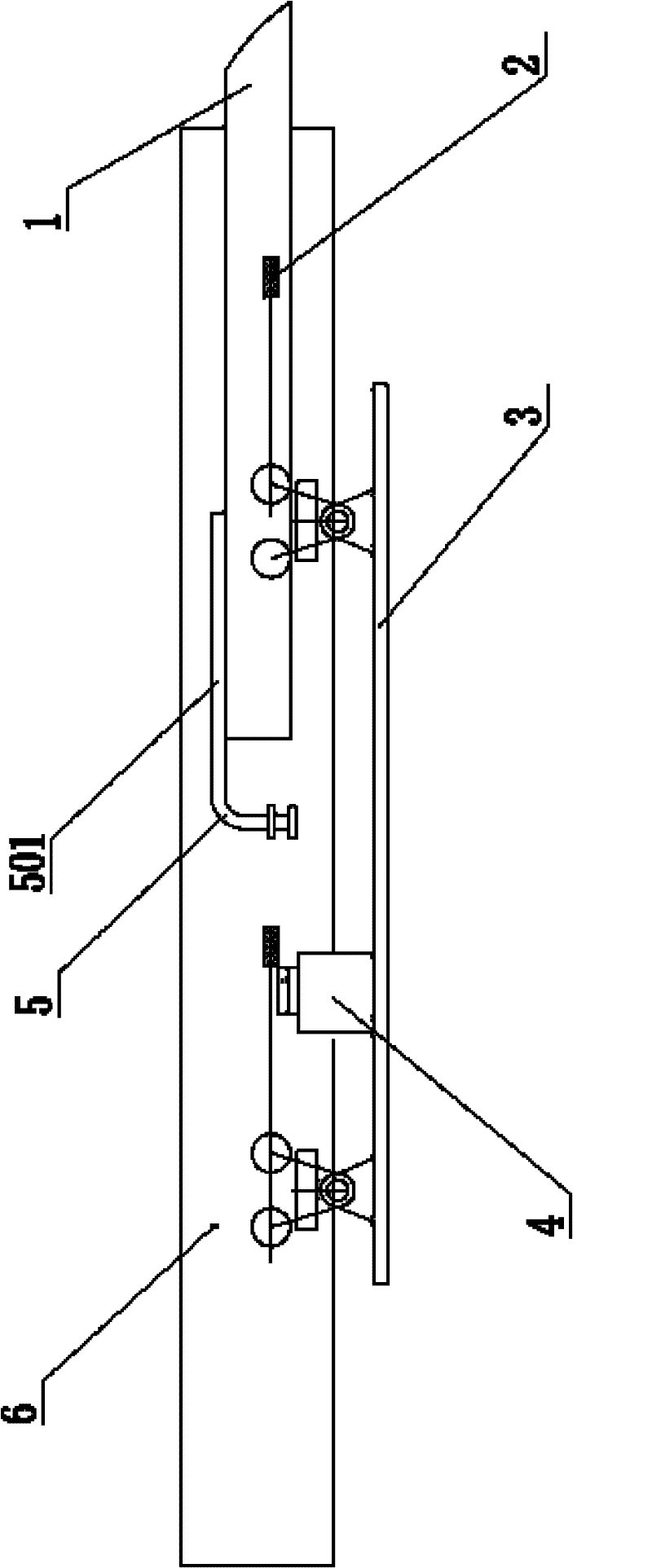

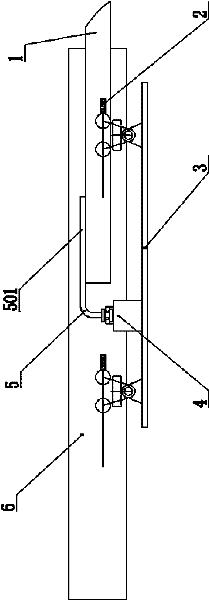

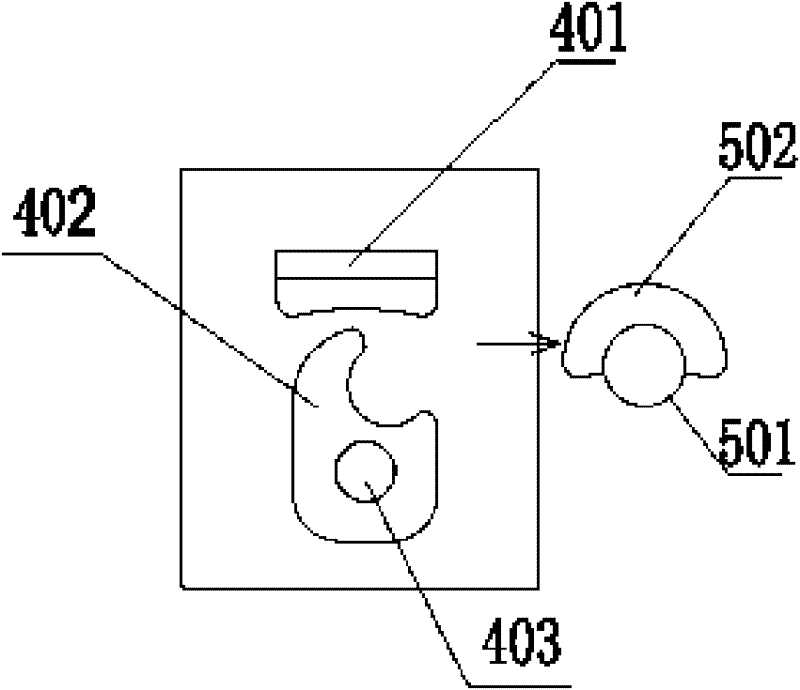

[0024] Such as figure 1 with figure 2 As shown, the present invention is used for the locking mechanism of the sliding door, and it comprises the fixed locking pile 5 and the positioning lock block device 4 installed on the door body 3, and the positioning lock block device 4 is connected with the door body 3 after the door body 3 is opened. The locking pile 5 cooperates to lock and locate the door body 3 . In this embodiment, the driver's cab applied to an engineering vehicle is taken as an example. The locking pile 5 is fixed on the vehicle body 1 and remains still, and the door body 3 can slide on the guide rail 6 to complete the opening and closing. see image 3 , Figure 4 with Figure 5 The positioning lock block device 4 includes a vertical limit block 401 and a dead bolt 402. The dead bolt 402 is fixed on the door body 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com