Manufacturing method of sheet assembly

A manufacturing method and joint body technology, applied to flat products, other household appliances, transportation and packaging, etc., can solve problems such as damage efficiency, accidental contact of sheet components, and damage to the next sheet component, and achieve the goal of suppressing quality degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

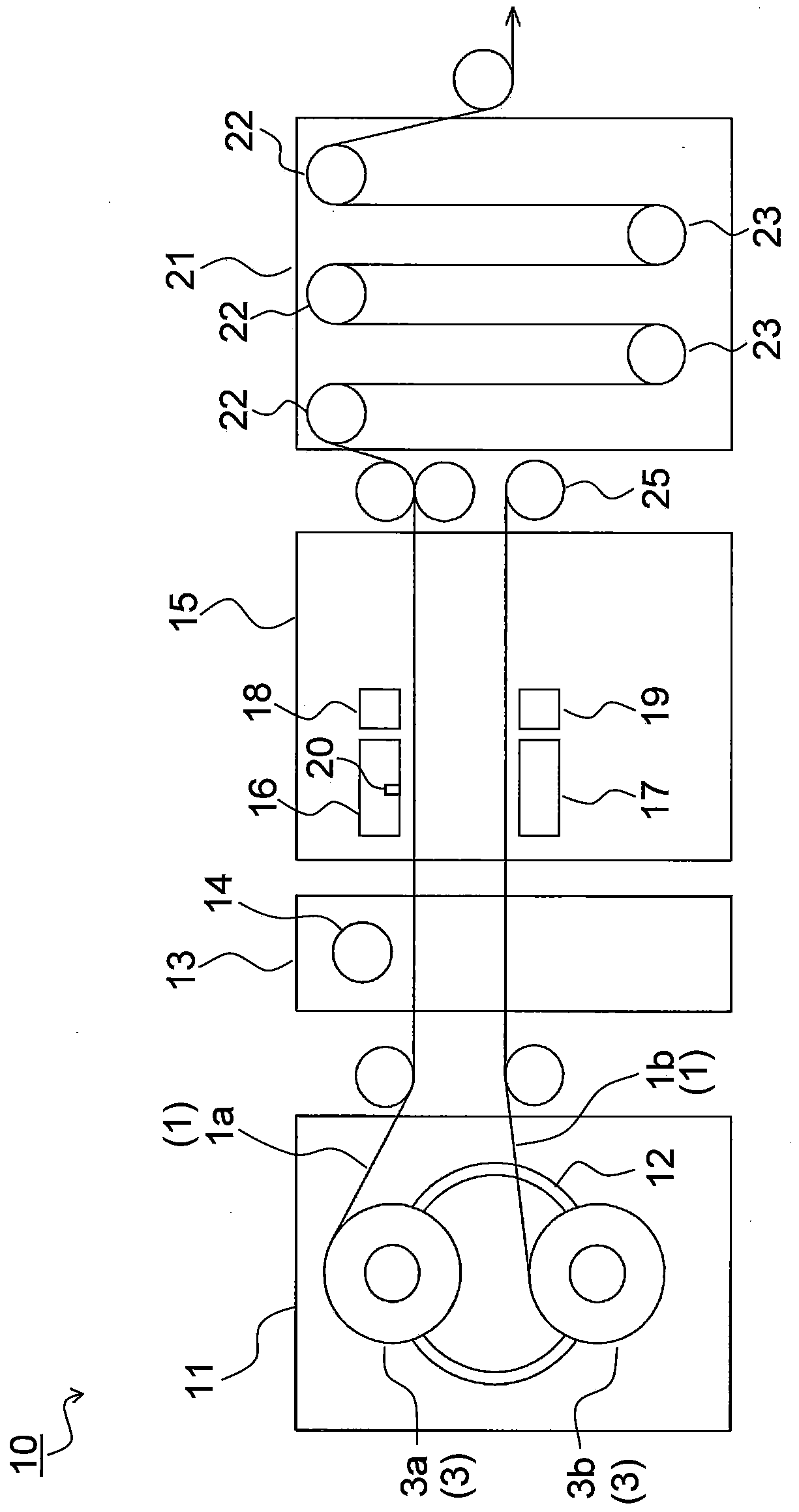

[0024] Next, a method of manufacturing the sheet assembly of the present invention will be described with reference to the drawings. First, the manufacturing apparatus of the sheet assembly used in the manufacturing method of this embodiment is demonstrated.

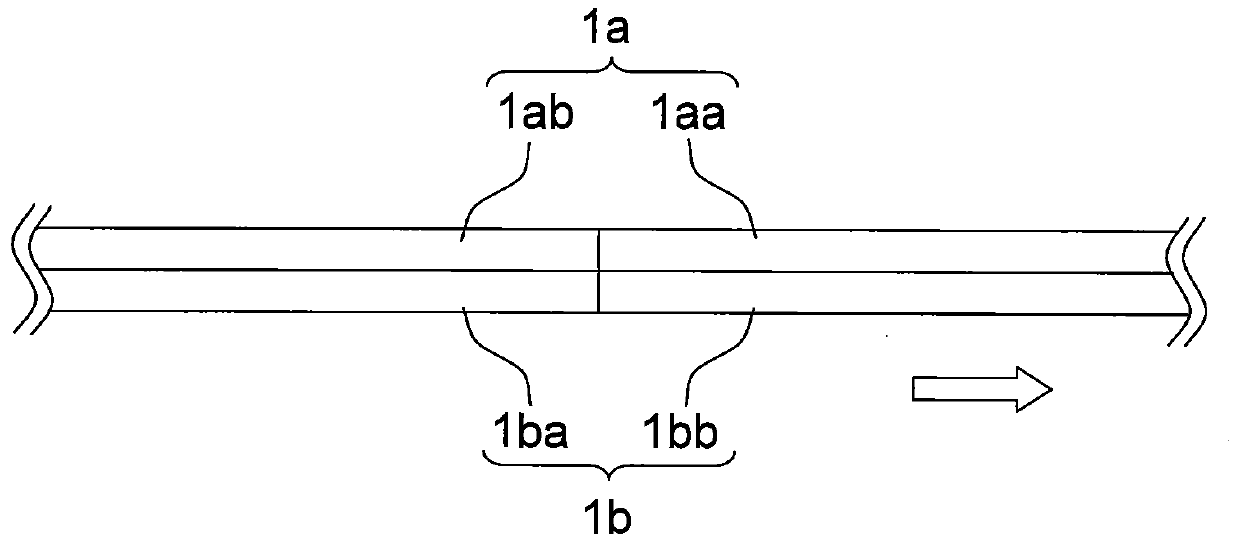

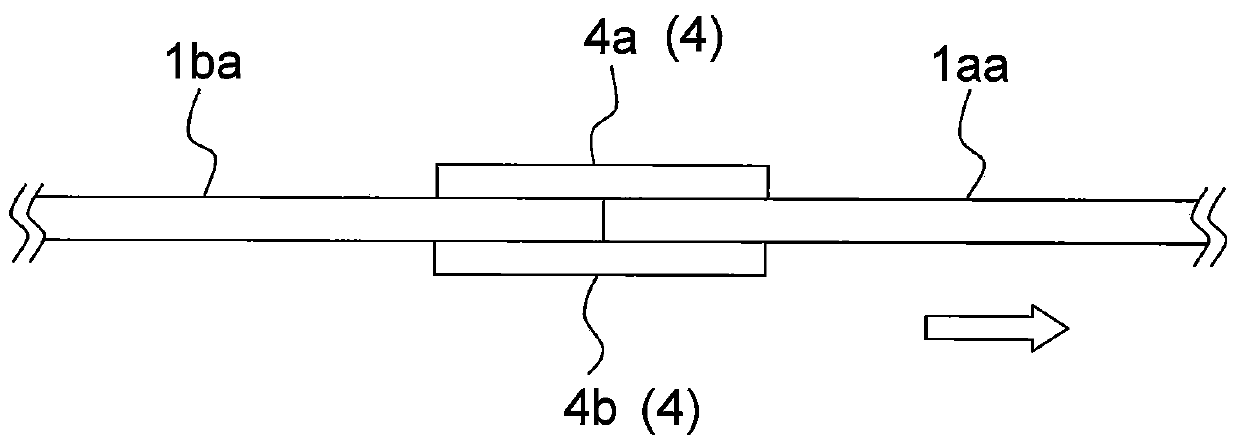

[0025] like figure 1 As shown, the manufacturing apparatus 10 of a sheet bonded body includes: a turntable unit 11 that places one of the two rolls 3 formed by winding a strip-shaped sheet member 1 on the upper side and the other roll on the lower side, and can Two volumes 3 are supported by exchanging their arrangement, and the sheet members 1 are respectively released from the above-mentioned rolls 3; the joining device 15 cuts off the top sheet member 1a discharged from the turntable part 11, and can make the formed part due to cutting. The end 1aa (cut end) is joined to the lower sheet member 1; the recovery part 13 is used to cut off the unnecessary part 1ab of the sheet member 1a by the joining device 15 (refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com