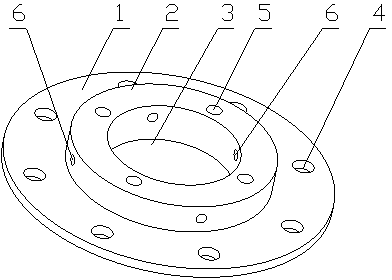

Integrated flange for mutual inductor

An integrated, transformer technology, applied in the direction of inductors, transformers, transformer/inductance components, etc., can solve problems such as poor sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0008] Such as figure 1 As shown, a transformer integrated flange includes a flange body 1, the flange body 1 is disc-shaped, and a circular boss 2 is provided in the middle, and a circular boss 2 is provided in the center of the flange body 1. Through hole 3 is evenly provided with a plurality of threaded through holes 4 on the circumference of described flange body 1, is evenly provided with a plurality of threaded through holes 5 on the upper surface of described circular boss 2, and its side is provided with at least Four pairwise symmetrical threaded holes 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap