Splicing clip for bellows units and application thereof

A corrugated pipe and compatible technology, applied in the field of splicing clips for corrugated pipe units, can solve problems such as the separation of arc-shaped corrugated pipe units due to gravity, the threat to the construction safety of dismantling personnel, and the large size of corrugated pipes, so as to achieve rapid alignment and improve Installation splicing efficiency, increase the effect of quick alignment and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

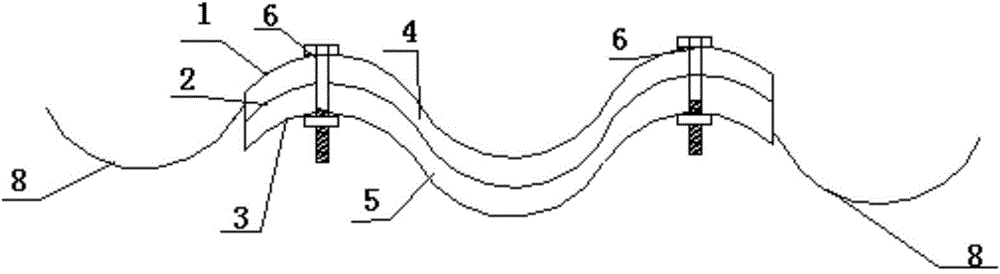

[0029] Such as figure 2 , 3 shown.

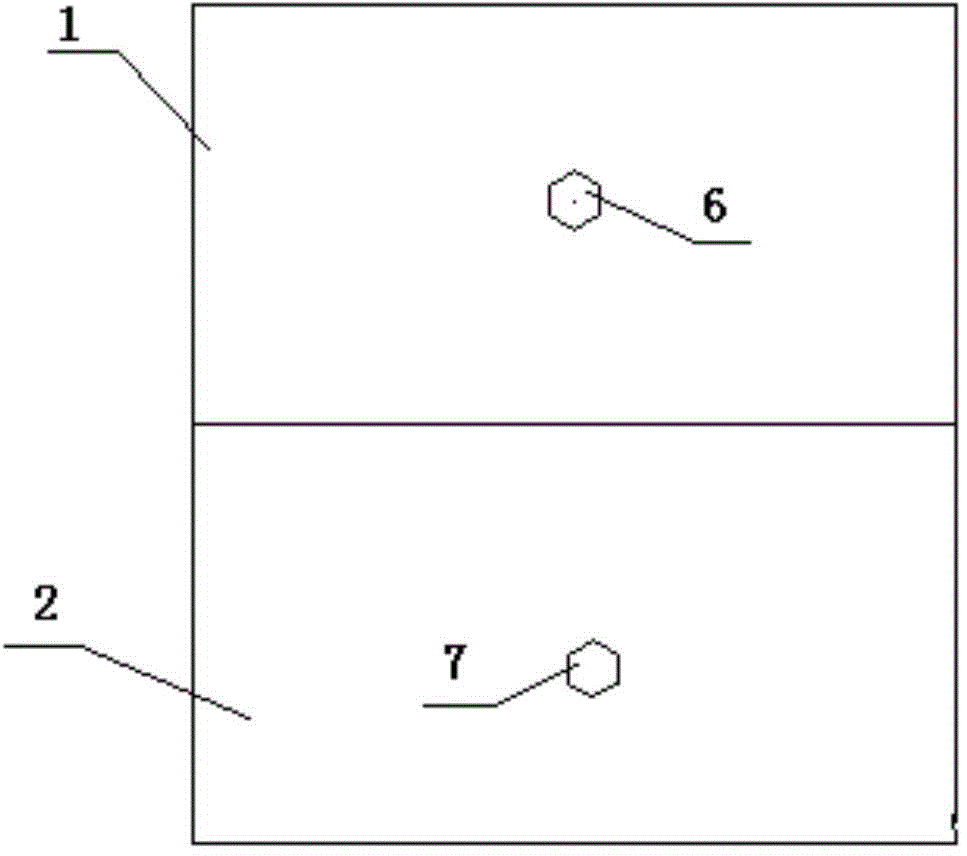

[0030] A bellows unit splicing clip, comprising three first guard plates 1, a support plate 2, and a second guard plate 3 arranged adjacent to each other. The first recess 4, the second guard plate 3 and the support plate 2 form the second recess 5 that accommodates the edge of the bellows unit; Mounting holes 6 are provided, and the mounting holes coaxially penetrating through the first guard plate, the support plate and the second guard plate form a group of mounting holes.

[0031] The length of the support plate 2 is greater than the first guard plate 1 and the second guard plate 3, and the end of the support plate 2 protrudes from the first guard plate 1 and the second guard plate 3, and at the protruding part of the support plate 2 A fixing hole 7 adapted to the splicing hole of the bellows unit 8 is provided on the top.

[0032] The number of the fixing hole 7 is one.

[0033] The arc shapes of the first guard plate 1 , the sup...

Embodiment 2

[0036] Such as Figure 4 shown.

[0037] A bellows unit splicing clip as described in Embodiment 1, the difference is that the number of the fixing holes 7 is two. Two sets of mounting holes are provided on the splicing clip of the bellows unit 8 .

Embodiment 3

[0039] A method for splicing bellows by using the bellows unit splicing clips as described in Embodiments 1 and 2, comprising the following steps:

[0040] (1) Snap the two pre-spliced bellows units 8 into the first recess 4 and the second recess 5 of the bellows unit splicing clip respectively, so that the edges of the two bellows units coincide;

[0041] (2) partially fixing the two bellows units 8 through the mounting holes 6 with bolts;

[0042] (3) After the preliminary fixing in step (2), the staff bolts the splicing holes of the two bellows units 8 one by one;

[0043] (4) Detach the splicing clip of the bellows unit, and finally bolt the splicing holes left on the two bellows units 8 in step (2).

[0044] In step (2), the two bellows units 8 are fixed by using bolts through the splicing holes of the bellows units 8 and the fixing holes 7 on the support plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com