Rectangular integrated radio frequency connector

A connector and radio frequency technology, applied in the direction of contact parts, fixed/insulated contact components, etc., can solve the problems of restricting the high-density integration of products, increasing the diameter of the radio frequency hole, and increasing the spacing of the radio frequency contacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

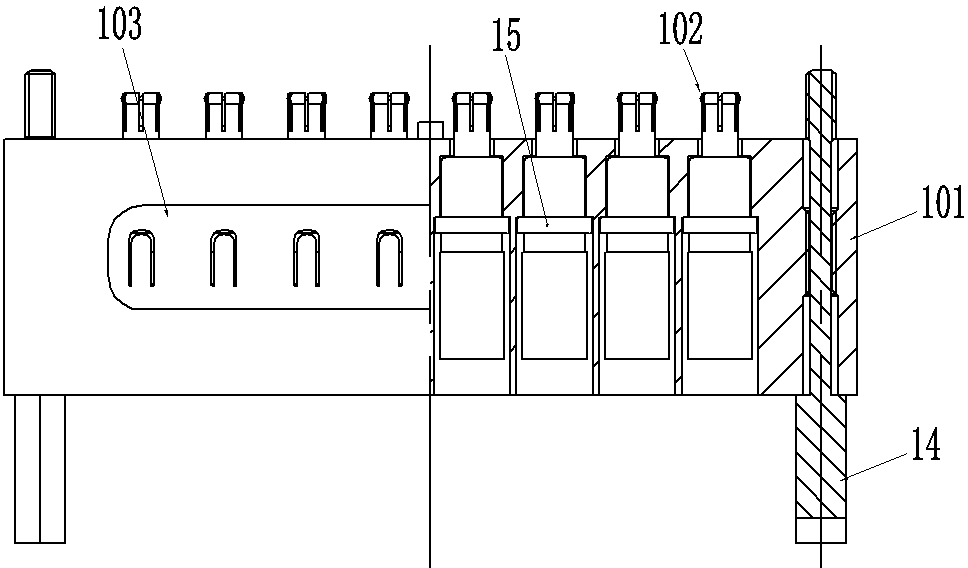

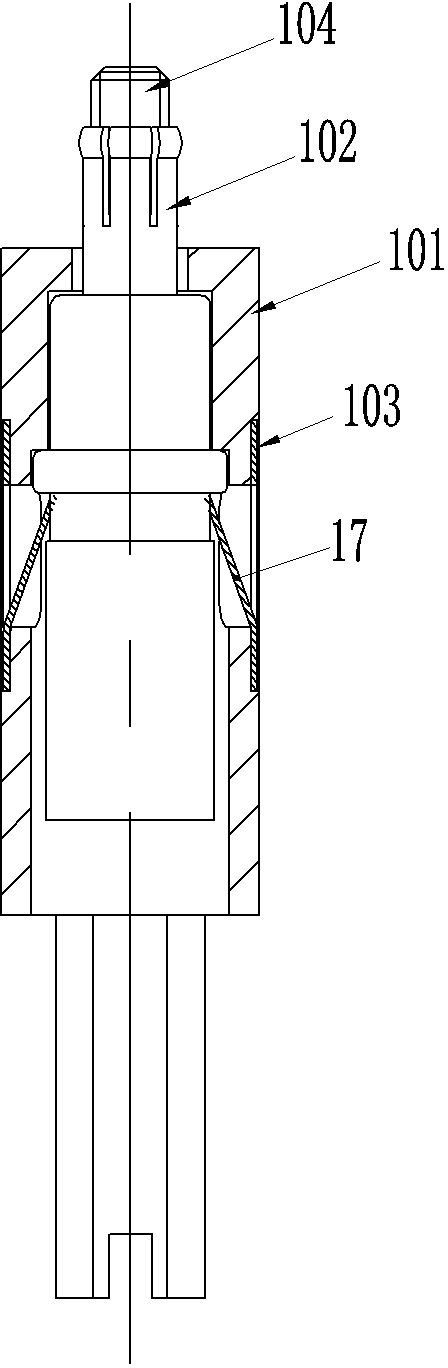

[0019] Examples of rectangular RF-integrated connectors, such as Figure 1-6 As shown, the connector has a front end as a plug-in end, and includes a housing 101 and a contact 102 .

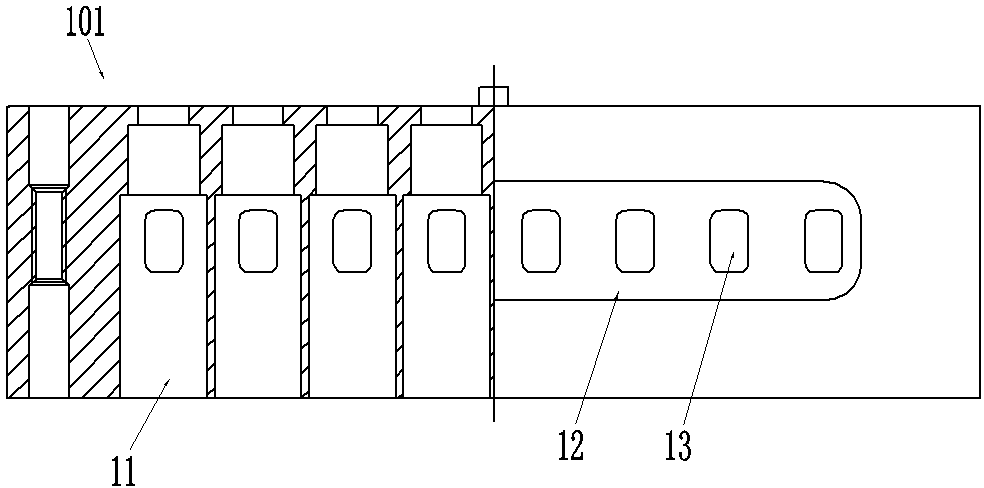

[0020] Such as image 3 As shown, the housing 101 is provided with a radio frequency hole 11, the radio frequency hole 11 is a three-stage stepped hole, and its aperture is gradually reduced from the back to the front. In this embodiment, there are eight radio frequency holes 11 and they are along the Arranged in the left and right directions, the radio frequency holes 11 are used for assembling the contacts 102 . In addition, the upper and lower sides of the housing 101 are respectively provided with attachment grooves 12 , and the bottom of the attachment groove 12 is provided with through windows 13 , and the windows 13 correspond to the radio frequency holes 11 one by one. Both ends of the housing 101 are respectively provided with connecting screw rods 14 for locking the connector and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com