A kind of preparation method of sensory plastic geogrid

A geogrid and sensor-type technology, applied in the field of civil engineering, can solve the problems of inability to strengthen the detection of solid deformation information, increase the difficulty and cost of detection, single reinforcement effect, etc., and achieve the effect of avoiding the decline in the accuracy of deformation testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the sensor type plastic geogrid of the present invention has the following steps:

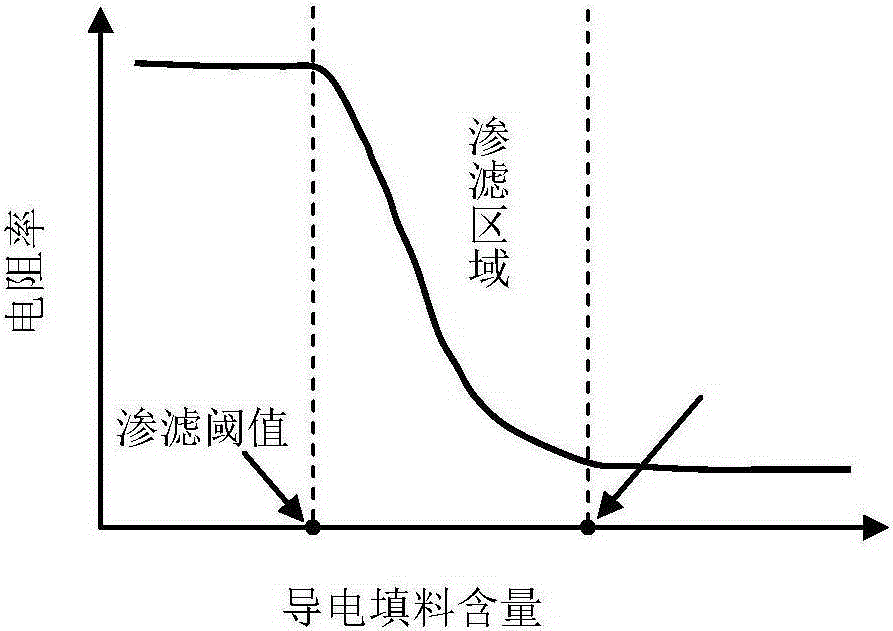

[0034] (1) Determination of filling amount of superconducting carbon black

[0035] In order to obtain the required composite material, the composite material is developed in an experimental way in the room. The high-density polyethylene is selected as the base material, and the conductive masterbatch with superconductive carbon black is used as the filler, and the conductive masterbatch accounts for the mass of the mixture. Melt and mix the two in the range of 40% to 60%. After plasticizing and extruding, they are cooled and pelletized to obtain a conductive composite material. In order to ensure the uniformity of the composite material, it is mixed and plasticized for multiple times. Granulate to obtain the required composite material for use.

[0036] (2) Calibration of smart polymer deformation-resistance relationship

[0037] Conducting a tensile test of conductiv...

example 1

[0044] Example 1: Preparation of sensing plastic geogrid for road

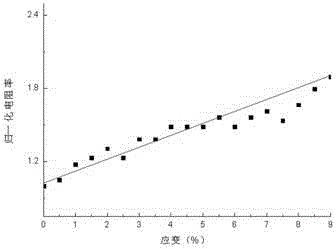

[0045] In road engineering, the geogrid is mainly used to reinforce the soil and prevent settlement. In order to prepare a sensor-type plastic geogrid suitable for roads, a conductive composite material with a filler ratio of 45% is selected (its normalized resistivity and strain The relation is Such as Figure 5 (Shown), the production process of the composite material of this ratio is as follows: the base material HDPE and superconducting carbon black masterbatch are prepared and mixed according to the mass ratio; the mixture of the two is melted and extruded through an extruder, and then pelletized after cooling. The high-density polyethylene composite material is obtained. In order to ensure the uniformity of the carbon black in the composite material, the prepared composite material particles are remelted and re-granulated, and the re-granulation process is repeated twice to obtain a composite material with ...

example 2

[0046] Example 2: Preparation of sensing plastic geogrid for mine

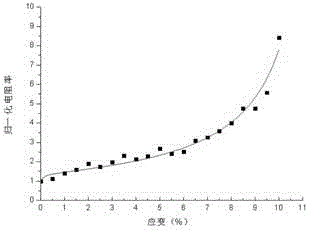

[0047] In mine production operations, the stability and firmness of the roadway is the guarantee of safe production. In order to reinforce the roadway, the method of burying geogrid is usually used, which not only improves the robustness of the roadway, but also reduces the construction cost. But even so, due to the effect of confining pressure and other factors, the roadway wall will still be deformed and destroyed, or even collapsed, causing loss of life and property. If special equipment is used for regular inspection, it will be time-consuming and labor-intensive and inconvenient to operate. The above problems can now be solved by laying a sensor-type geogrid. The composite conductive high-density polyethylene composite material (carbon black is conductive filler) with a filler mass ratio of 48% is selected as the raw material (the normalized resistivity and strain relationship is Ω Ω 0 = ϵ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com