Three sets of elastic self-sealing safety valves

A self-sealing, safety valve technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve problems such as unstable valve action performance, failure to meet standard requirements, and large user feedback, to achieve easy action repeatability, stability, The action repeatability is stable and reliable, and the effect of improving the adjustment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

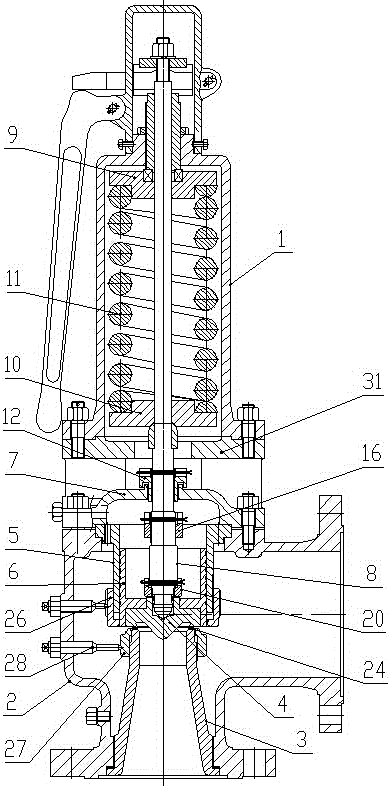

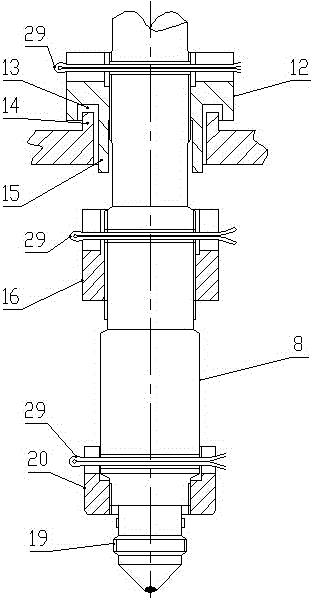

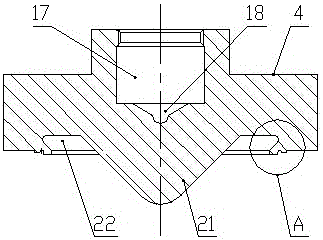

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, three sets of elastic self-sealing safety valves of the present invention include a valve cover 1, a valve body 2, a valve seat 3, a valve disc 4, a guide cylinder 5, a sleeve 6, a lower cooling fin 7, an upper cooling fin 31 and a valve Rod 8, described bonnet 1 is provided with upper spring seat 9, lower spring seat 10 and the spring 11 that two ends are respectively inserted into upper spring seat 9, lower spring seat 10, described upper spring seat 9, spring 11, The lower spring seat 10 is threaded on the outside of the valve stem 8 in sequence, the valve cover 1, the upper cooling fin 31, the lower cooling fin 7, and the valve body 2 are fixedly connected by bolts in turn, and the valve seat 3 is placed in the valve body 2 and located on the valve body. At the lower end of the body 2, the guide cylinder 5 is fixed at the junction of the lower cooling fin 7 and the valve body 2, the guide cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com