Solid wood imitated lock type aluminum floor

An aluminum alloy, imitation solid wood technology, applied in the direction of floor, building, building structure, etc., can solve the problem of not tight enough lock, and achieve the effect of tight lock and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

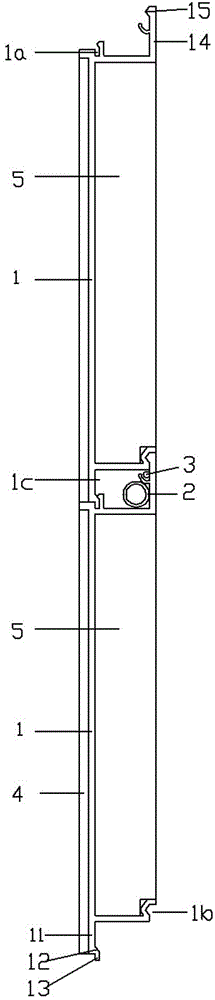

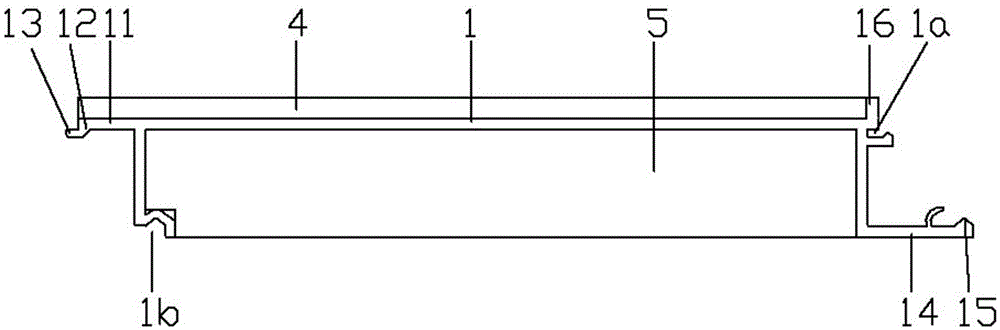

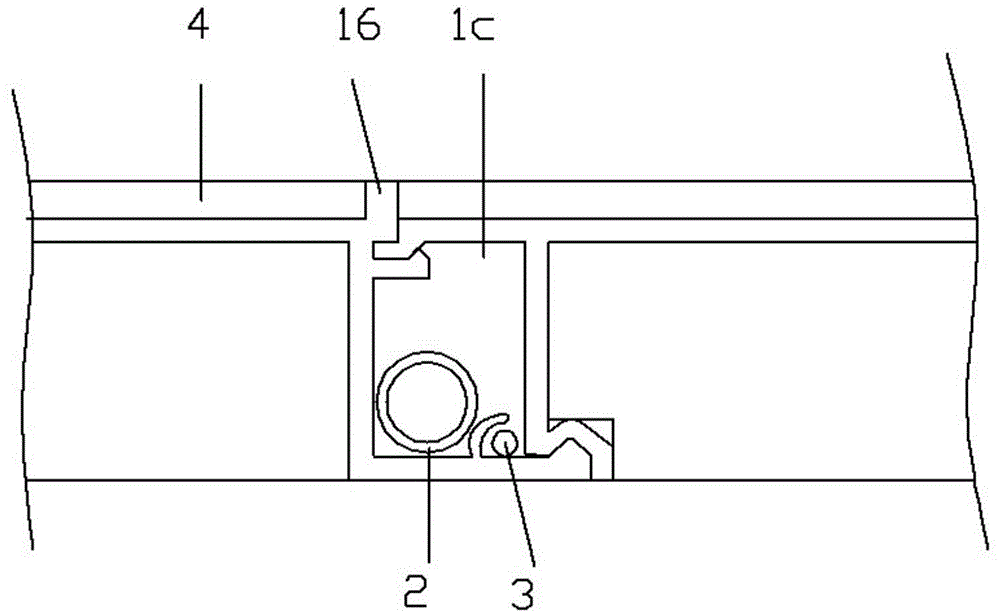

[0027] Example 1: see Figures 1 to 3 As shown, a solid wood-like lock-type aluminum alloy floor includes a support block 5, an upper horizontal tenon 11 extends from the upper left side of the floor plate 1, and a vertically upward tenon 12 is formed on the left end of the upper horizontal tenon 11, which is inserted vertically upward. The lower part of the left end face of the tenon 12 is formed with a small horizontal tenon 13; the lower part of the right side of the floor board 1 is extended with a lower horizontal tenon 14, and the right end of the lower horizontal tenon 14 is formed with a vertical downward tenon 15;

[0028] The upper slot 1a and the lower slot 1b are formed on the floor board 1, and the vertical upper tenon 12 and the small horizontal tenon 13 of the two adjacent floor boards 1 are inserted and sleeved on the other floor board. In the upper slot 1a, the vertical lower tenon 15 on one floor board 1 is inserted into the lower slot 1b on the other floor b...

Embodiment 2

[0032] Example 2, see Image 6 , 7 As shown, the lower surface of the floor board 1 is higher than the lower surface of the support block 5 . All the other are with embodiment 1.

Embodiment 3

[0033] Example 3, see Figure 8 As shown, the floor board 1 is formed with a support block transverse tenon 1e, and the support block transverse tenon 1e is inserted into the matching slot of the support block 5). All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com