Vehicle tire

A technology for tires and vehicles, applied in special tires, vehicle parts, tire parts, etc., to solve problems such as slow, uneven transmission of vehicles, and lack of directional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

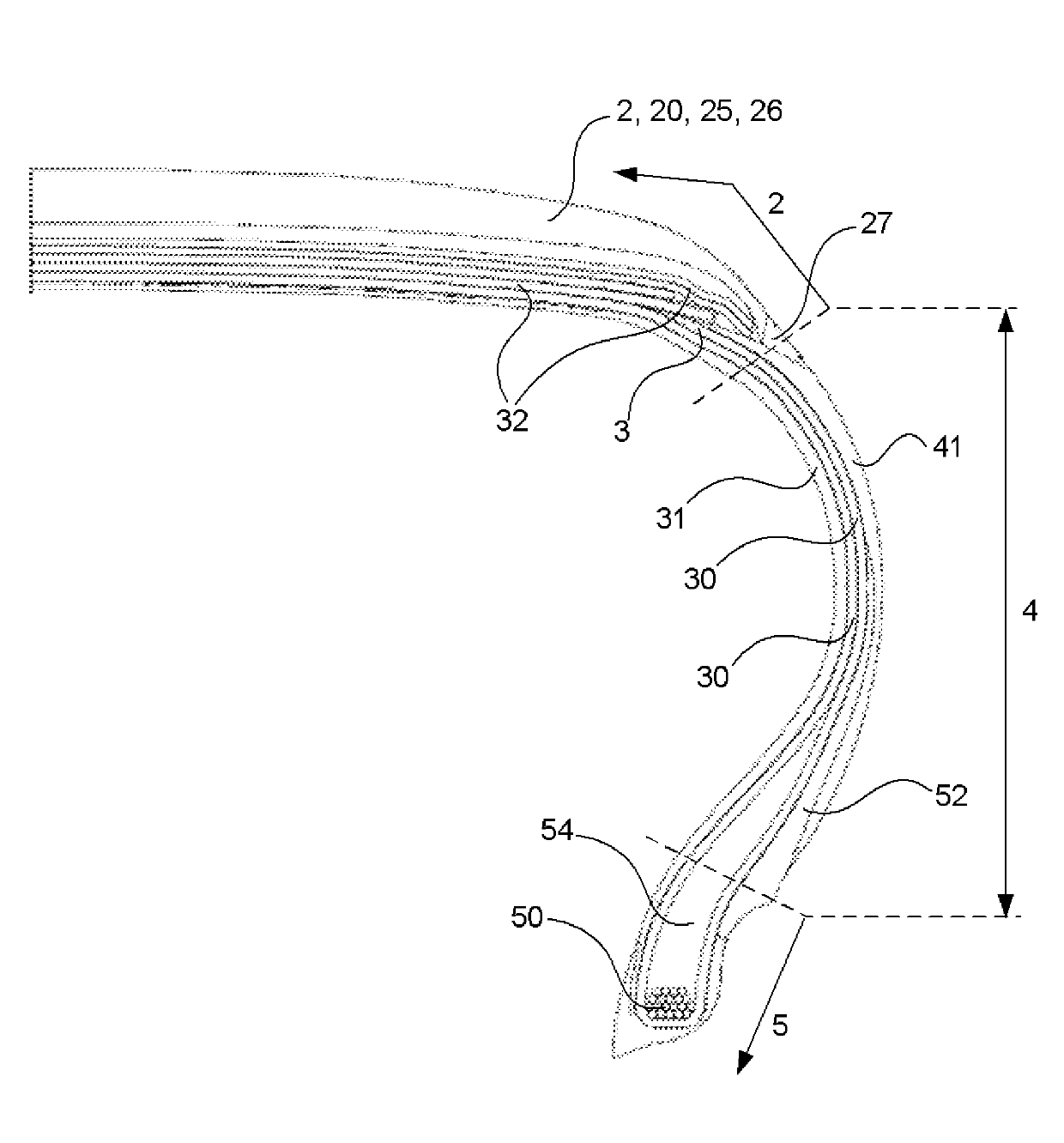

[0042] using the arrows, figure 1 The regions that may be considered to be included in the bead area 5 , the sidewall 4 and the tread 2 are generally indicated. The arrowed areas are not exact and in various tire compositions these locations can be slightly different. With regard to the carcass 3 , the figures refer only to individual components, but the carcass covers almost the entire cross-sectional area of the tyre.

[0043] According to a preferred embodiment, the aramid fibers have a length of 3±1 mm, preferably 3±0.5 mm. In addition, according to a preferred embodiment, the aramid fiber has a diameter of 5-30 μm. Individual strands of aramid fibers within the range defined by these dimensions have given particularly good results in tire research work.

[0044] exist figure 1 In the embodiment shown, said outermost sidewall layer 41 of the vehicle tire is the layer immediately outwards from the body cords 30 . In this solution, possible slash or puncture forces fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com