Hoisting and Suspension Method of Axial Flow Paddle Turbine Runner

A water turbine and runner technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of inconvenient operation and many processes, and achieve the effect of ensuring convenience, reducing processes and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

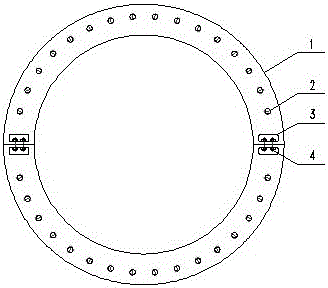

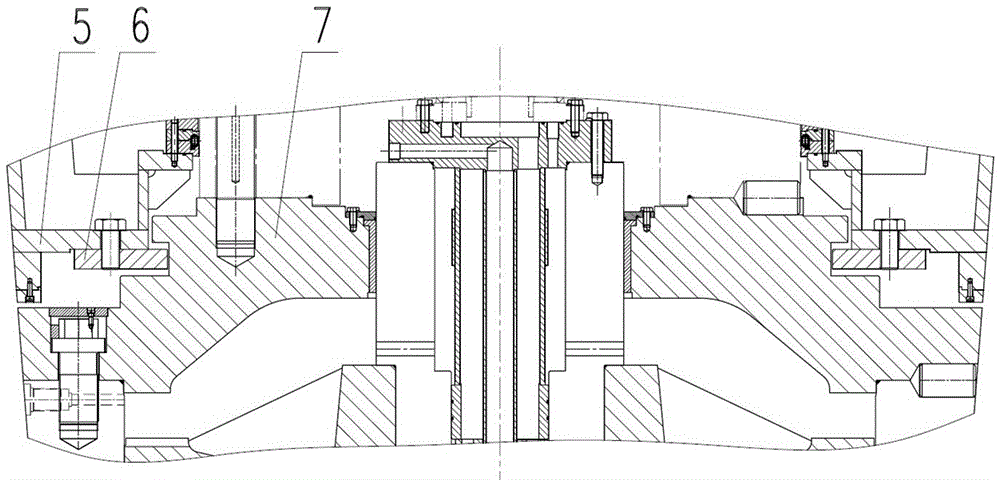

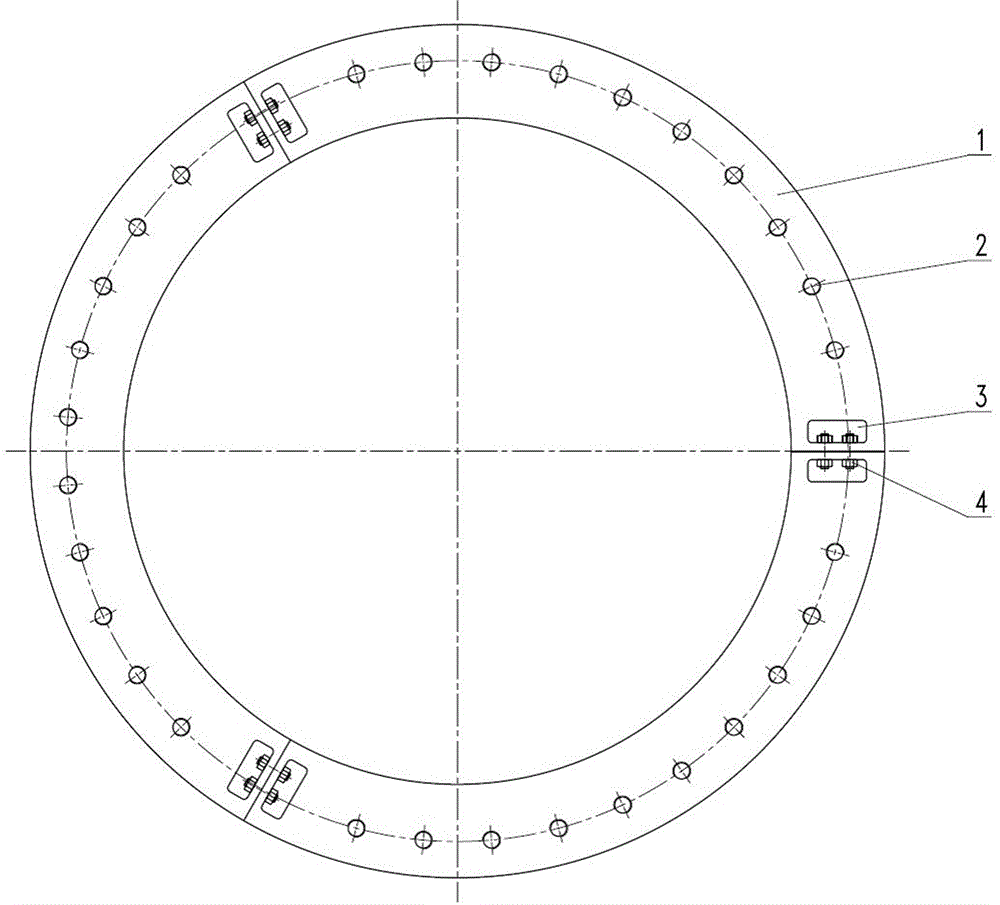

[0066] The hoisting and suspension snap ring of the runner of the axial flow paddle type water turbine in this embodiment is composed of two arc-shaped snap ring bodies connected end to end to form a ring. Screw holes; both ends of the clasp body are provided with inner digging cavities, and the inner digging cavities are provided with connectors connecting the two clasps. The connectors in this embodiment are bolts. The principle of this embodiment is to process a ring groove on the outer edge of the cylinder head of the runner servomotor as a clamping ring and the force-bearing area of the runner suspension; to process screw holes on the flange surface of the lower part of the diversion cone to snap ring, so that it is combined with the diversion cone. As a matter of course, the inner diameter of the snap ring should match the ring groove of the cylinder head of the runner servomotor; in order to connect the snap ring with the guide cone, when the snap ring snaps into the ...

Embodiment 2

[0069] The hoisting and suspension snap ring for the runner of the axial-flow paddle-type water turbine in this embodiment includes a three-lobed arc-shaped snap ring body, and the snap ring body is evenly distributed with screw holes for connecting the snap ring body and the turbine diversion cone. The use method of this embodiment is to process a ring groove on the outer edge of the cylinder head of the runner servomotor as a snap ring to snap into and the force-bearing area of the runner suspension; to process screw holes on the flange surface of the lower part of the diversion cone to The clasp ring is combined with the diversion cone; when in use, first snap the three clasp bodies into the ring groove of the cylinder head of the runner servomotor, and then use the screw hole to guide the clasp ring and the turbine cone. As a matter of course, the inner diameter of the snap ring should match the ring groove of the cylinder head of the runner servomotor; in order to conne...

Embodiment 3

[0071] The hoisting and suspension clasps of the runner of the axial flow paddle type water turbine in this embodiment are formed by four-lobed arc clasps connected from end to end to form a ring, and the clasps are evenly distributed with holes for connecting the clasps and the diversion cones of the water turbine. Screw holes; both ends of the clasp body are provided with inner digging cavities, and the inner digging cavities are provided with connectors connecting the two clasps. The connectors in this embodiment are bolts. The principle of this embodiment is to process a ring groove on the outer edge of the cylinder head of the runner servomotor as a clamping ring and the force-bearing area of the runner suspension; to process screw holes on the flange surface of the lower part of the diversion cone to snap ring, so that it is combined with the diversion cone. As a matter of course, the inner diameter of the snap ring should be compatible with the ring groove of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com