Environment-friendly type polymer emulsion building waterproof coating

A polymer emulsion, building waterproofing technology, applied in the direction of coating, can solve the problems of living environment hazards, elasticity index and stability cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

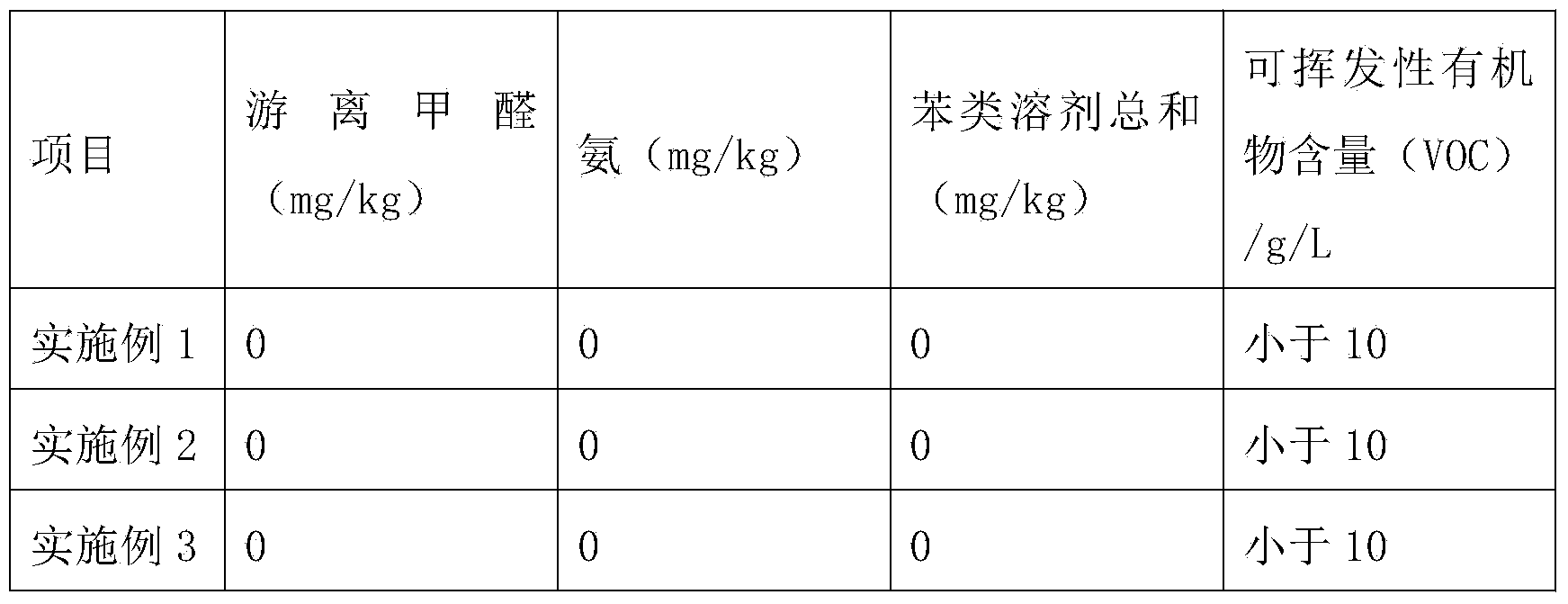

Examples

Embodiment 1

[0020] Premixed powder: 10 weights of 800 mesh kaolin, 15 weights of 350 mesh quartz powder, 15 weights of 600 mesh wollastonite, 10 weights of 600 mesh mica powder, 3 weights of titanium dioxide with an average particle size of 30nm, and 2 weights of 20 nanometer silicon dioxide. Micropowder, 8 weights of 400 mesh diatomaceous earth are premixed at high speed in a horizontal mixer for 15 minutes, and set aside;

[0021] After fully dispersing 80 wt. of Celanese 1350 emulsion, 1 wt. of defoamer, and 63 wt.

Embodiment 2

[0023] Premixed powder: 10 weights of 800 mesh kaolin, 10 weights of 400 mesh quartz powder, 20 weights of 400 mesh wollastonite, 15 weights of 600 mesh mica powder, 3 weights of titanium dioxide with an average particle size of 15nm, and 3 weights of 30 nanometer silicon dioxide. Micropowder, 10 weights of 500 mesh diatomaceous earth are premixed in a horizontal mixer for 10 minutes at high speed, and set aside;

[0024] After fully dispersing 85 weights of Celanese 1603 emulsion, 2 weights defoamer, and 71 weights of premixed powder, add 7 weights of 0.5% titanium dioxide photocatalyst to obtain an environment-friendly polymer emulsion building waterproof coating.

Embodiment 3

[0026] Premix powder: 15 weights of 600 mesh kaolin, 10 weights of 400 mesh quartz powder, 15 weights of 500 mesh wollastonite, 18 weights of 700 mesh mica powder, 10 weights of titanium dioxide with an average particle size of 50nm, and 5 weights of 50 nanometer silicon Micropowder, 12 weights of 450 mesh diatomite are premixed in a horizontal mixer for 20 minutes at high speed, and set aside;

[0027] After fully dispersing 100 wt. of polyacrylate emulsion, 3 wt. of defoamer, and 85 wt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com