Clamp for repairing pipe

A clamp and pipe technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of reducing installation work efficiency, difficult to connect clamp bolts, and investing a long time, so as to improve the installation work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

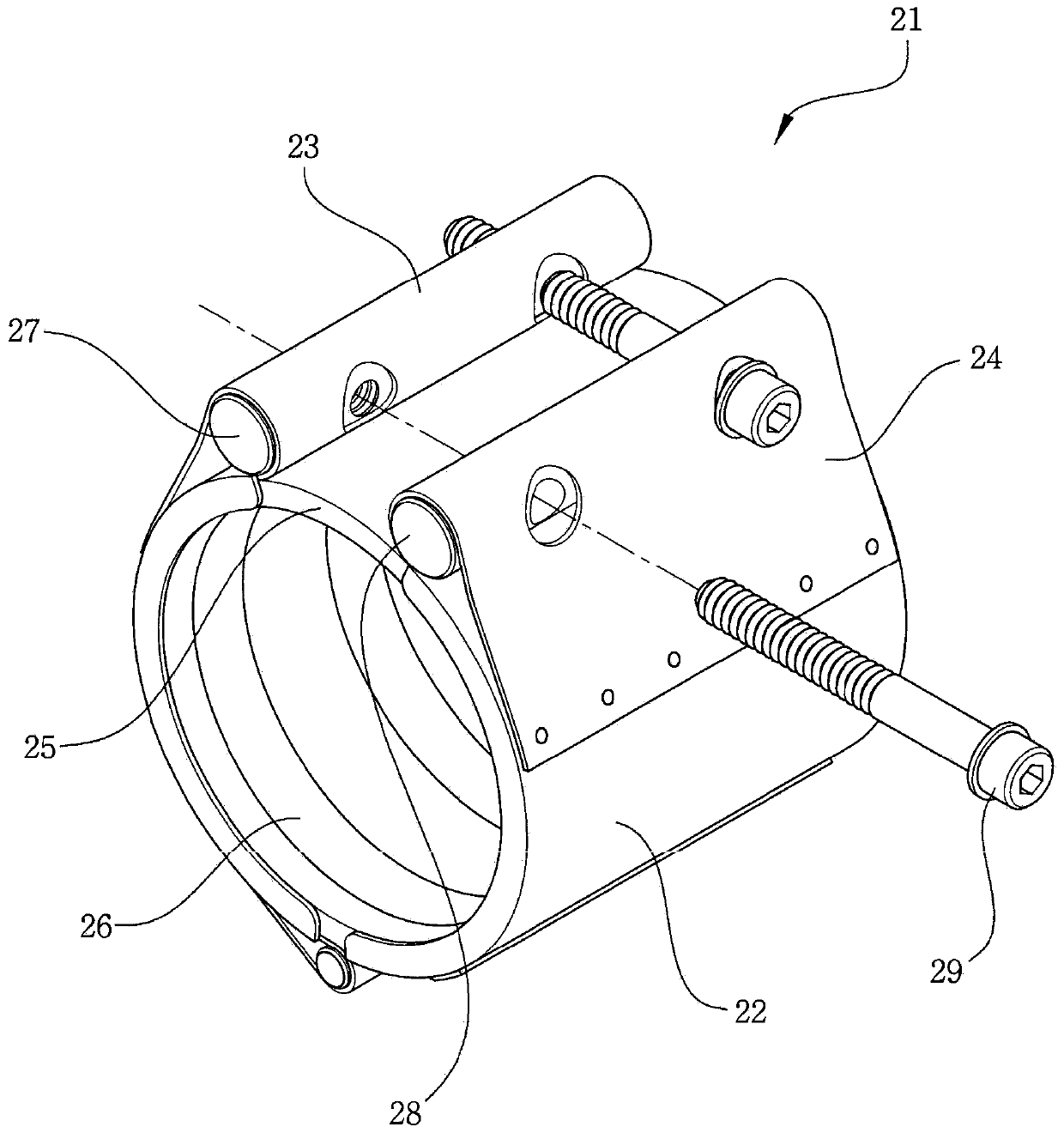

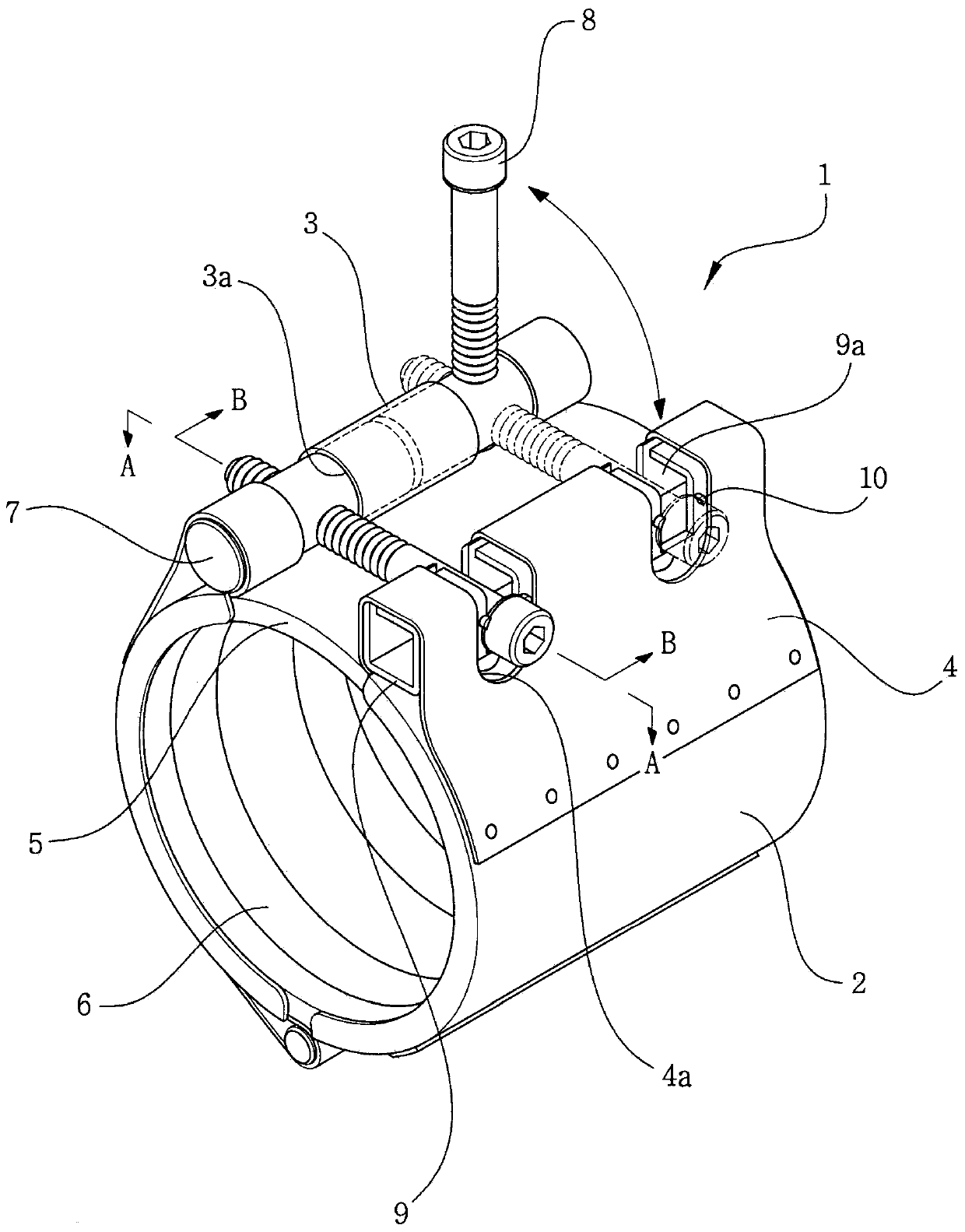

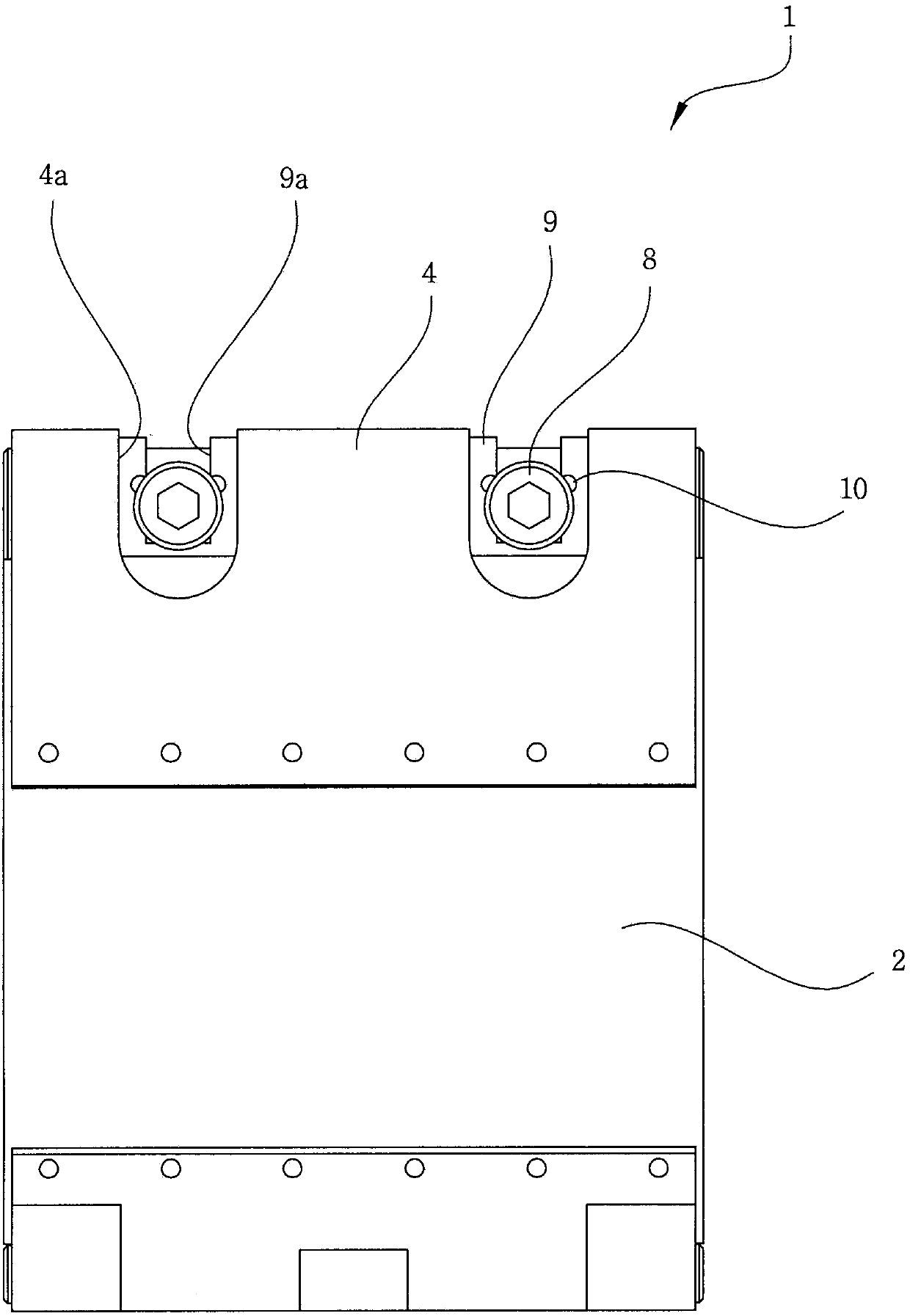

[0027] In order to achieve the above-mentioned object of the present invention, refer to figure 2 or Image 6 , as detailed below:

[0028] The clamps for pipe maintenance of the present invention are used to quickly repair the leaking part of the pipe, as figure 2 , consists of a main body 2 wrapped around a pipe and a sealing sleeve 6 installed on the inner surface of the main body 2 .

[0029] The above-mentioned main body 2 is that the upper part of the main body has an incision part formed in the longitudinal direction, and the incision part is the center, which can be opened or closed to both sides. The main body is in the shape of a circular tube.

[0030] The above-mentioned main body 2 is made of an auxiliary material in the shape of a circular tube, or two auxiliary materials in the shape of a semicircular tube connected by a hinge.

[0031] The nut mounting part 3 and the washer mounting part 4 of the above-mentioned main body 2 have a double number of bolt tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com