A reactor pressure vessel external cooling system

An external cooling and pressure vessel technology, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve the problems of no nanofluid technology, application of patent applications, etc., achieve high reliability and increase the effect of CHF value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

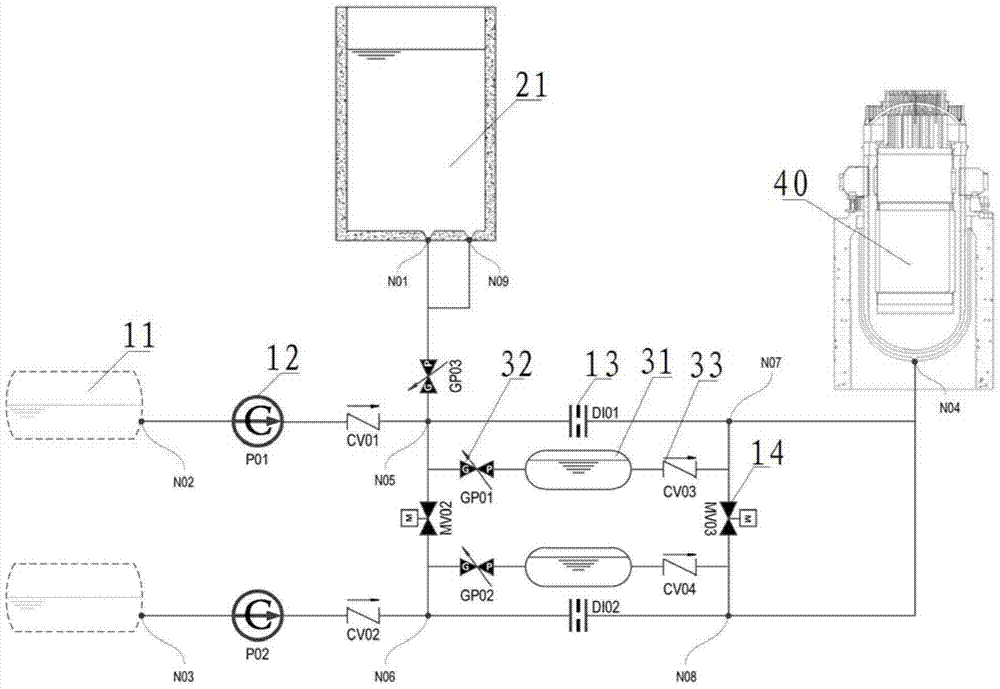

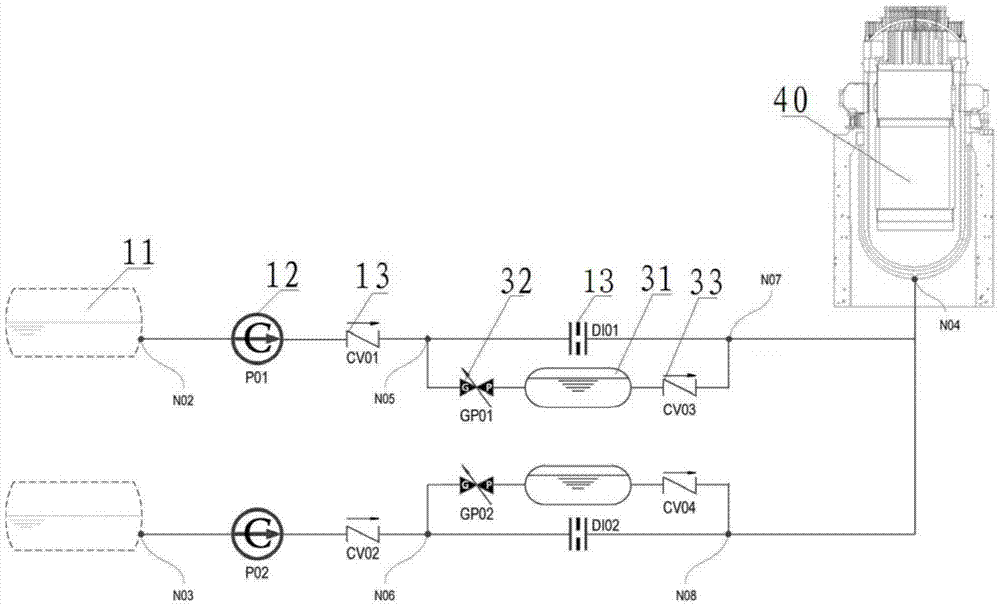

[0031] like figure 2 As shown, the external cooling system of the reactor pressure vessel in this embodiment is provided with two active injection paths, that is, two active injection units 10 are included, and two nanofluid units 30 are also provided, wherein the marks NO1-NO9 in the figure Indicates different nodes on the path, PO1 and PO2 are two active injection pumps 12, CV01-CVO4 are outlet check valves 33, GP01-GP03 are generalized passive fluid control units 32, DI01 and DI02 are flow calibration orifice plates 13, MV02 and MV03 are electric isolation valves 14 .

[0032] In this embodiment, in order to save the space occupied by the system, a common section, that is, a pipeline between N05→N07 and N06→N08, is set between the active injection path and the passive injection path. The two active injection paths are: N02→N05→N07→N04, N03→N06→N08→N04; the passive injection path is: N01&N09→N05&N06→N07&N08→N04. Two nanofluid storage tanks 31 are connected in parallel wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com